Floret bataloni

A technology of interweaving cloth and spun silk, applied in the field of textiles, can solve the problems of high proportion of Tencel and spun silk raw materials, difficult or even impossible to spin, and expensive production, and achieves good drape, rich elasticity and luster. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

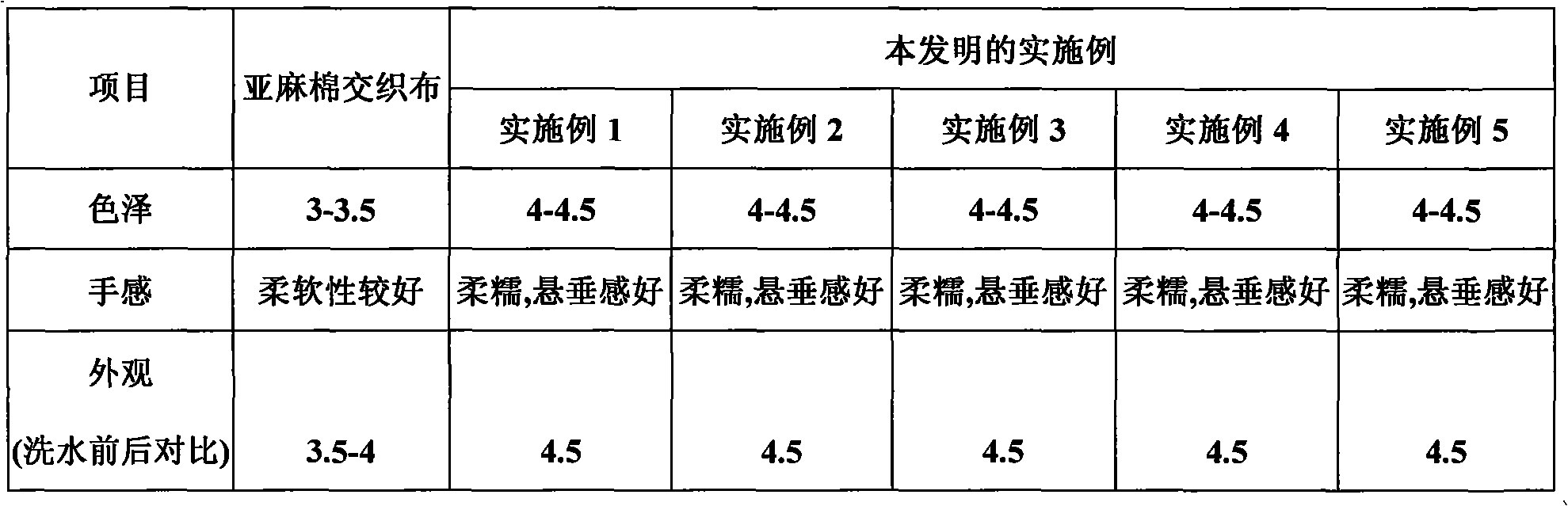

Examples

Embodiment 1

[0016] Cotton yarn with a specification of 40S is used as the warp yarn; spun silk with a specification of 80N / 2 and linen yarn with a specification of 28N are used as weft yarns. interval, wherein: the weight percentage of cotton yarn in the interwoven cloth is 52%, the weight percentage of spun silk in the interwoven cloth is 20%, and the weight percentage of linen yarn in the interwoven cloth is 28%. Utilize conventional production technology and equipment commonly used in the prior art to obtain silk, linen and cotton interwoven fabrics with a twill weave structure through finishing, pulping, weaving, scouring and bleaching, dyeing and finishing.

Embodiment 2

[0018] Cotton yarn with a specification of 60S is used as the warp yarn; spun silk with a specification of 210N / 2 and linen yarn with a specification of 36N are used as weft yarns. interval, wherein: the percentage by weight of cotton yarn in the interwoven cloth is 54%, the percentage by weight of spun silk in the interwoven cloth is 18.7%, and the weight percentage of linen yarn in the interwoven cloth is 27.3%, The weave structure of the obtained interwoven cloth is satin weave. All the other are the same as the description of embodiment 1.

Embodiment 3

[0020] Change the cotton yarn to 80S, change the percentage by weight in the interwoven fabric to 48%, change the specification of spun silk to 140N / 2, and change the percentage by weight in the interwoven fabric to 18.6%, and change the weight percentage of the linen yarn to 140N / 2. The specification is changed to 39N, and the percentage by weight in the interwoven cloth is changed to 33.4%. All the other are the same as the description of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com