Valve seat structure of self-decompression ball valve

A self-releasing, valve seat technology, applied in the valve seat field, can solve problems such as valve leakage, and achieve the effect of prolonging the service life, easy to use, and simple in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

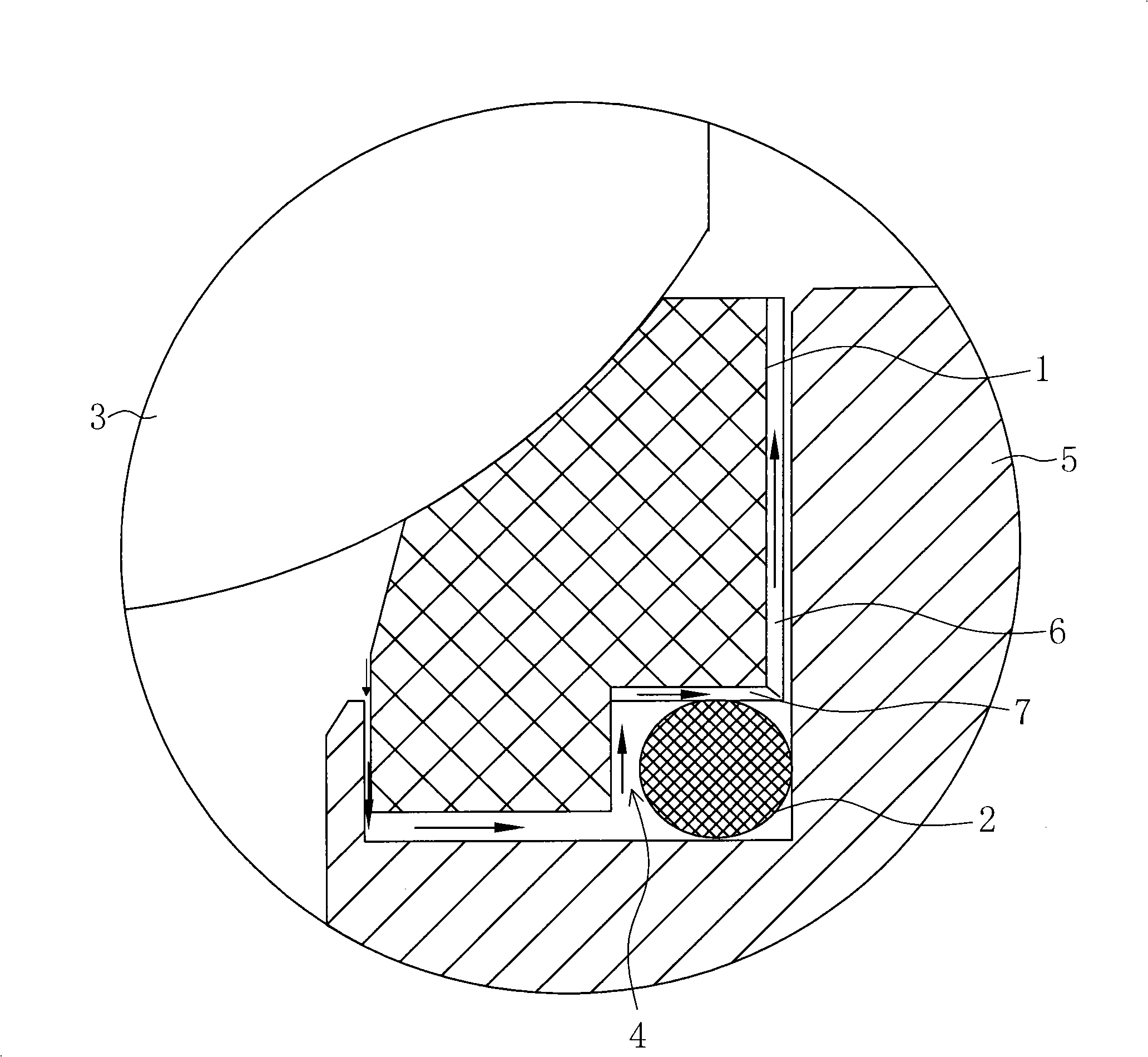

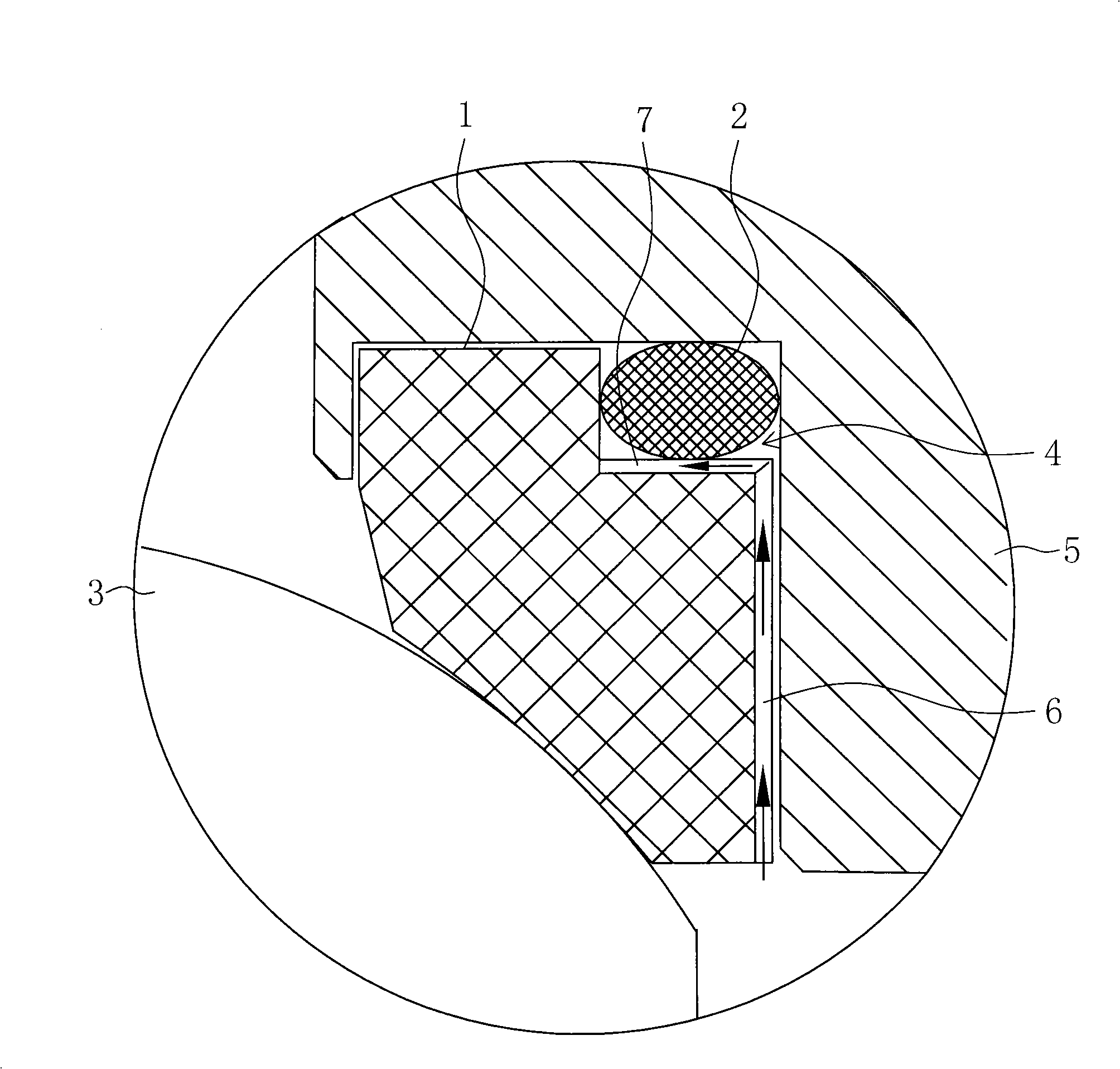

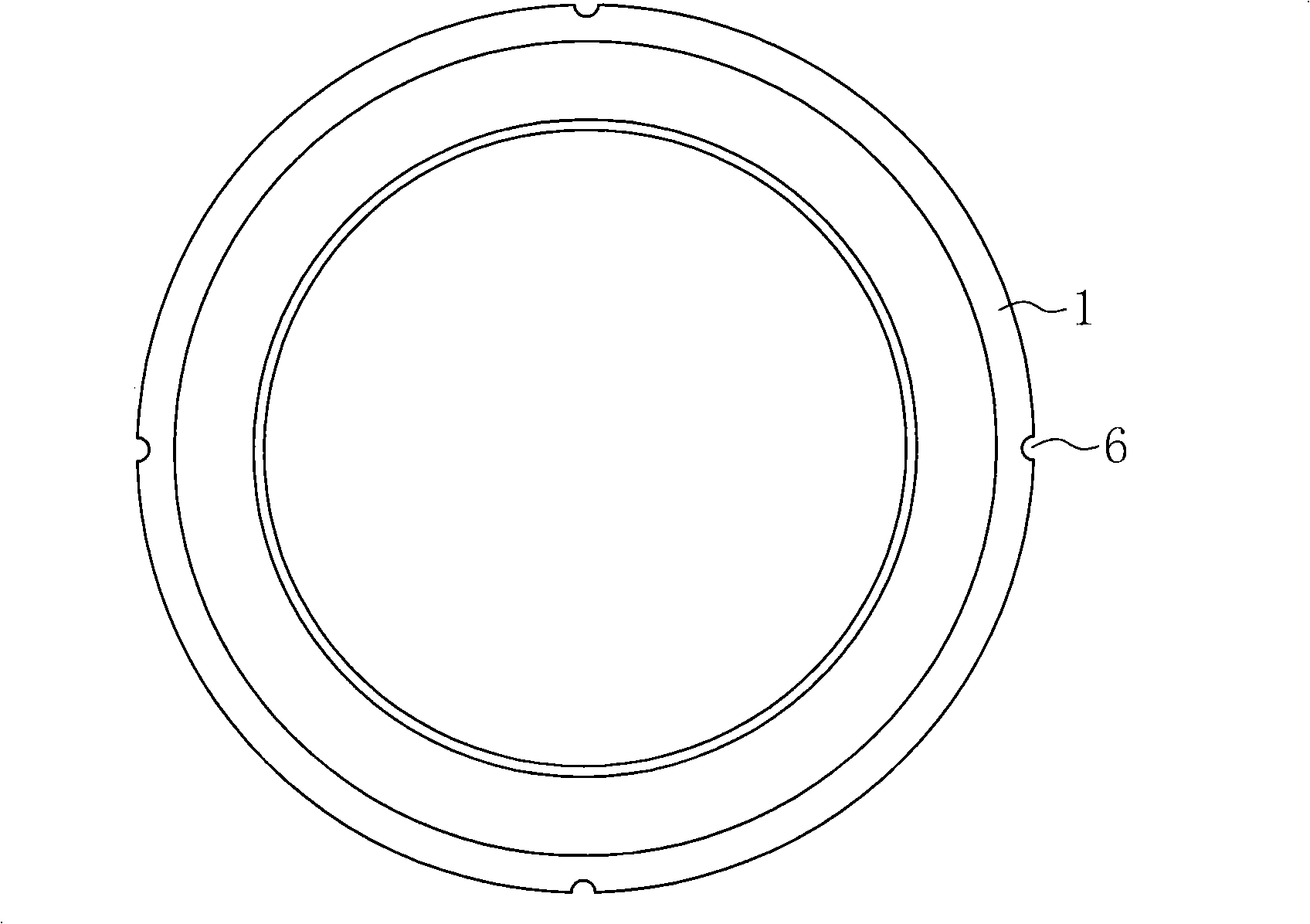

[0022] see Figure 1~4 As shown, a self-relieving ball valve seat structure includes a body 1, one side of the body 1 is bonded to the valve ball 3 to form a sealing surface, and the outer corner of the other side is provided with an annular gap 4, which is formed by cooperating with the valve cover 5 The ring channel that accommodates the O-ring 2, the outer wall of the valve seat 1 is provided with at least two pressure relief grooves 6 uniformly distributed in the circumferential direction, and the inner wall of the annular gap 4 adjacent to the outer wall of the valve seat is correspondingly provided with The pressure relief groove 6 communicates with another pressure relief groove 7 .

[0023] In the above, the direction of medium entry is from bottom to top, figure 1 The medium enters the inner cavity from the inlet end of the ball valve through the pressure relief groove, figure 2 The medium medium is sealed by the valve seat and O-ring at the outlet end and cannot b...

Embodiment 2

[0026] A self-relieving ball valve seat structure, including a body, one side of the body is bonded with the valve ball to form a sealing surface, and the outer corner of the other side is provided with an annular gap, which cooperates with the valve cover to form a ring for accommodating an O-ring. The outer wall of the valve seat is provided with at least two pressure relief grooves uniformly distributed in the circumferential direction, and another pressure relief groove communicating with the pressure relief groove is correspondingly provided on the inner wall of the annular gap adjacent to the outer wall of the valve seat .

[0027] In the above, the number of pressure relief grooves on the outer wall of the valve seat is 8 and arranged axially, and the number of pressure relief grooves on the inner wall of the annular notch is also 8 and arranged radially, and communicate with the pressure relief grooves respectively . This situation is suitable for the occasion of high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com