Equipment for separating mesocarp and oil gland layer of orange peel

A technology of orange peel and white skin layer and oil cell layer is applied in the field of fruit processing equipment, which can solve the problems of poor quality, high efficiency and low output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: (An orange peel segmentation device 1 and its application in segmenting Huyou peel)

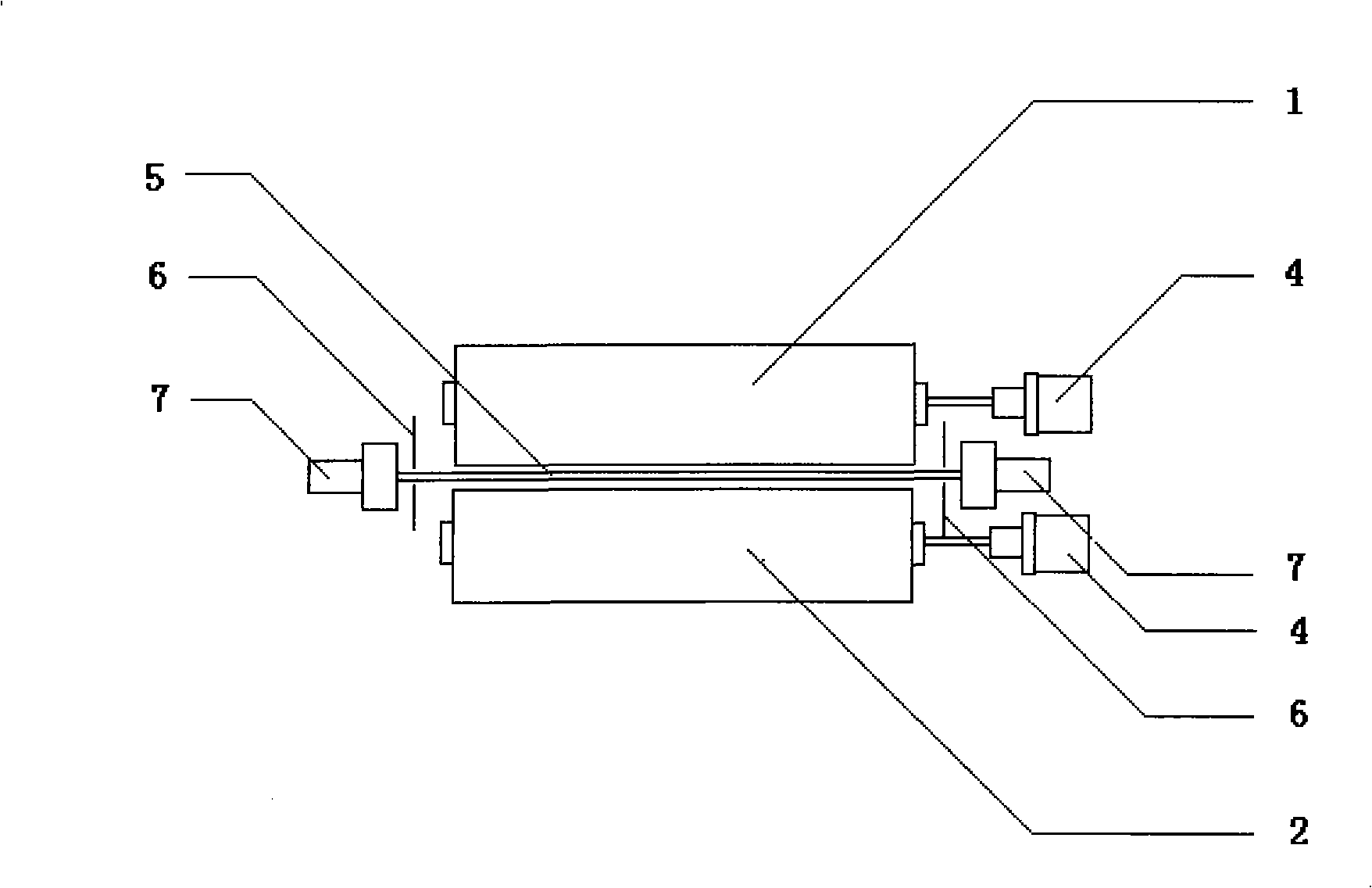

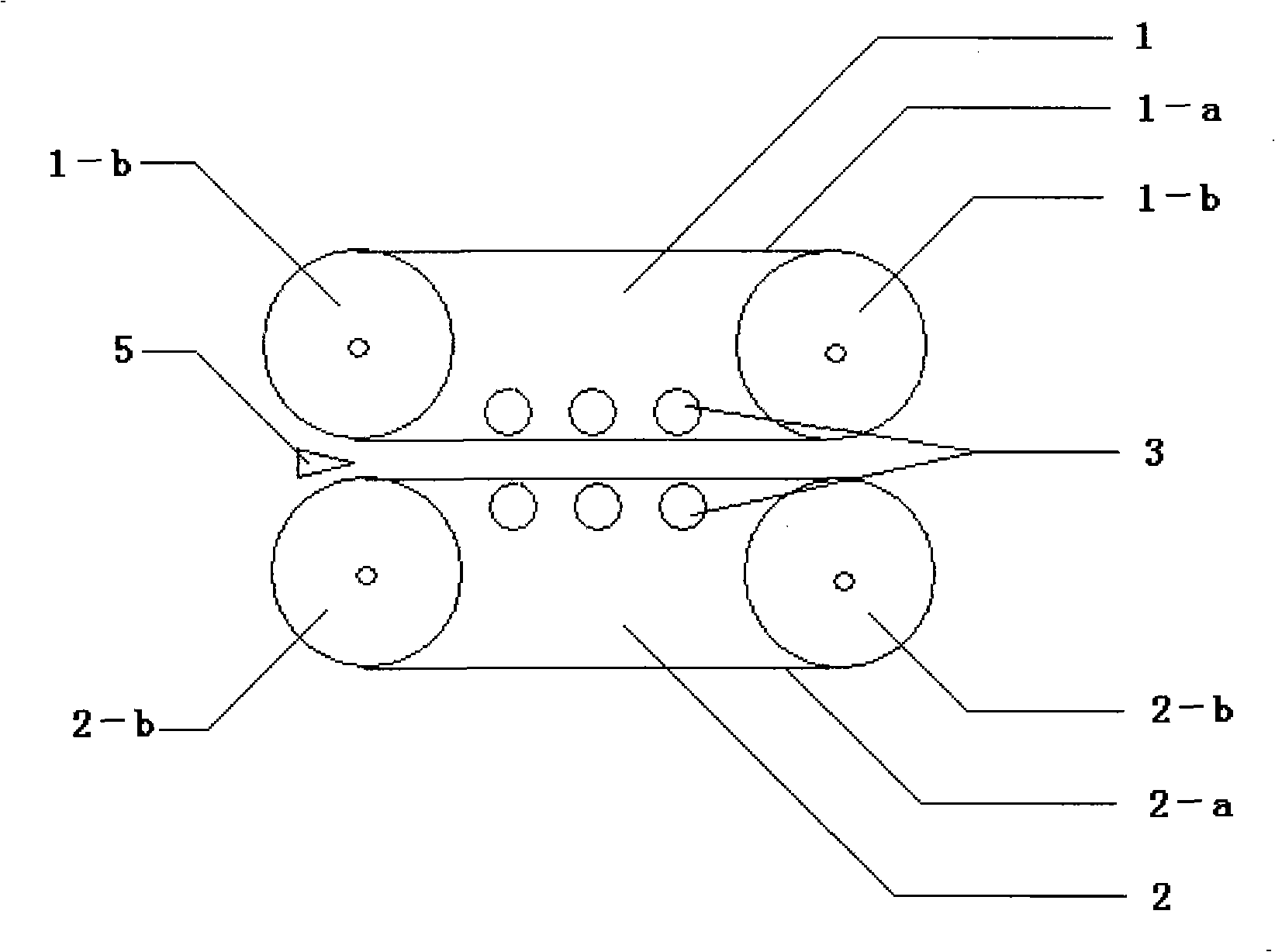

[0020] A device for separating orange peel white skin layer and oil cell layer, the device consists of: upper orange peel conveyor belt (1), lower orange peel conveyor belt (2), pressing roller (3), conveyor belt power device (4), cutter (5) ), a tool positioning device (6) and a tool power transmission device (7); wherein the upper orange peel conveyor belt (1) consists of an annular rubber material belt (1-a) and a rubber-coated metal material roller (1) -b), the lower orange peel conveyor belt (2) is composed of an endless rubber belt (2-a) and a rubber-coated metal roller (2-b). The roller (1-b) and the roller (2-b) are respectively It is movably connected with the power transmission device (4), the two orange peel conveyor belts (1, 2) are combined up and down in parallel, and a 2mm spacing is maintained between the two interlayers to form an orange peel conveyor system; on...

Embodiment 2

[0022] Embodiment 2: (An orange peel segmentation device 2 and its application in segmenting Wenzhou orange peel)

[0023] The belts (1-a, 2-a) of the orange peel conveyor belt (1, 2) of this equipment are all rubber materials; the rollers (1-b, 2-b) are all metal materials; the cutter (5) is without Tooth blade; the distance between the upper and lower conveyor belts (1, 2) after being pressed by the pressing roller (3) is 1mm; the cutter (5) is fixed, and the cutting edge is away from the lower orange belt (2) belt (2- a) 0.2mm; the rotating speed of the drum is 60 rpm, and the power of 100 watts can cut 80-90kg Wenzhou mandarin per hour. The rest of the equipment structure and use process in this example are the same as those in Example 1.

Embodiment 3

[0024] Embodiment 3: (An orange peel segmentation device 3 and its application in segmenting orange peels)

[0025] The belts (1-a, 2-a) of the orange peel conveyor belt (1, 2) of this equipment are all rubber materials; the rollers (1-b, 2-b) are all rubber-coated metal materials; the cutter (5) is Ring band saw; the distance between the upper and lower conveyor belts (1, 2) after being pressed tightly by the pressing rollers (3) is 1.5mm; the cutter (5) is fixed, and the cutting edge is away from the lower orange belt (2) belt (2-a) At 0.5mm; the rotating speed of the drum is 80 rpm, and the power of 150 watts can cut 120-130 kg orange peel per hour. The rest of the equipment structure and use process in this example are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com