Back adhesive surface joint method and joint apparatus thereof

A bonding device and skin technology, applied in the direction of lamination devices, chemical instruments and methods, layered products, etc., can solve the problems of skin bonding efficiency, easy to dirty the surrounding environment, shaking, shutdown cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

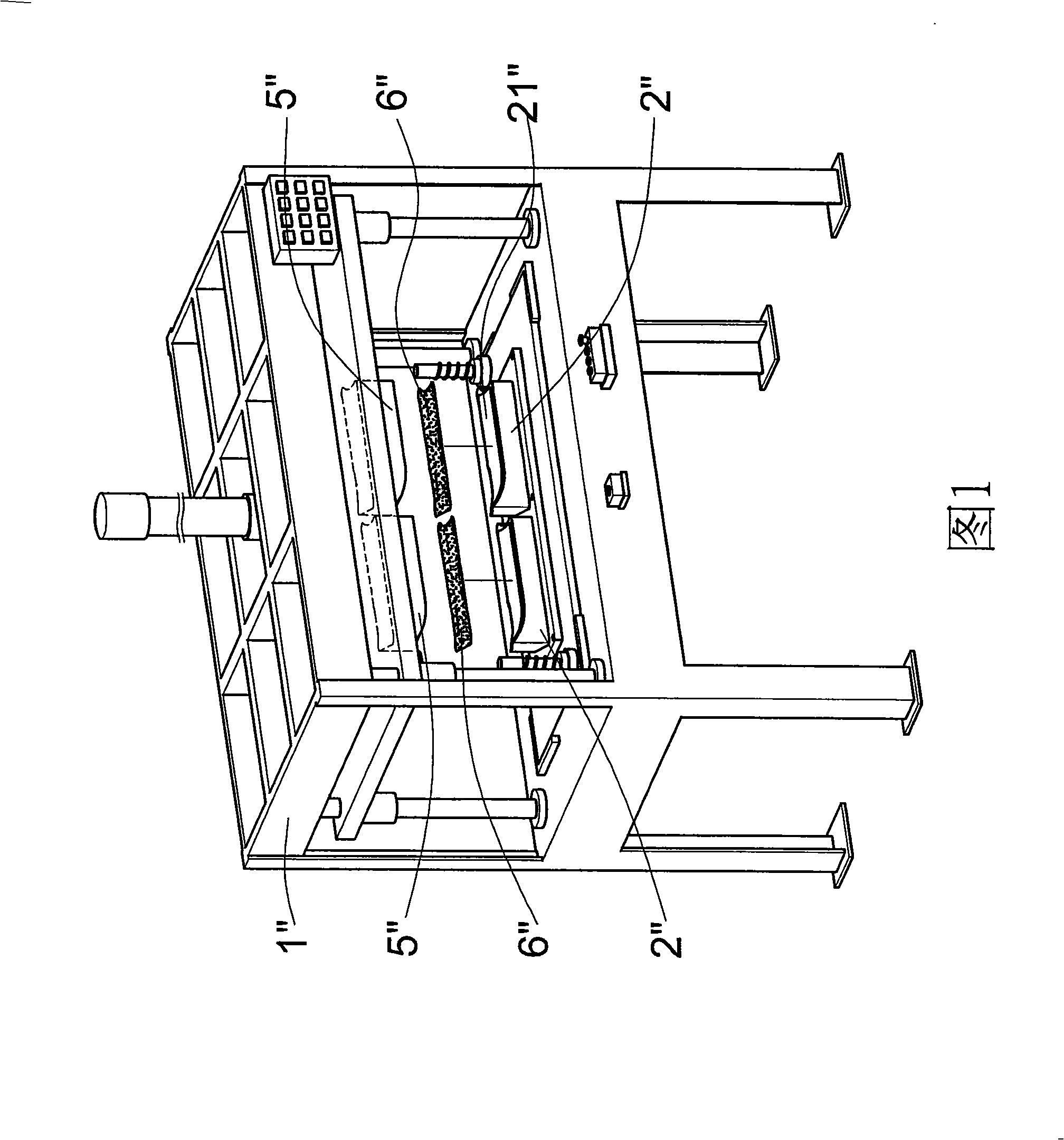

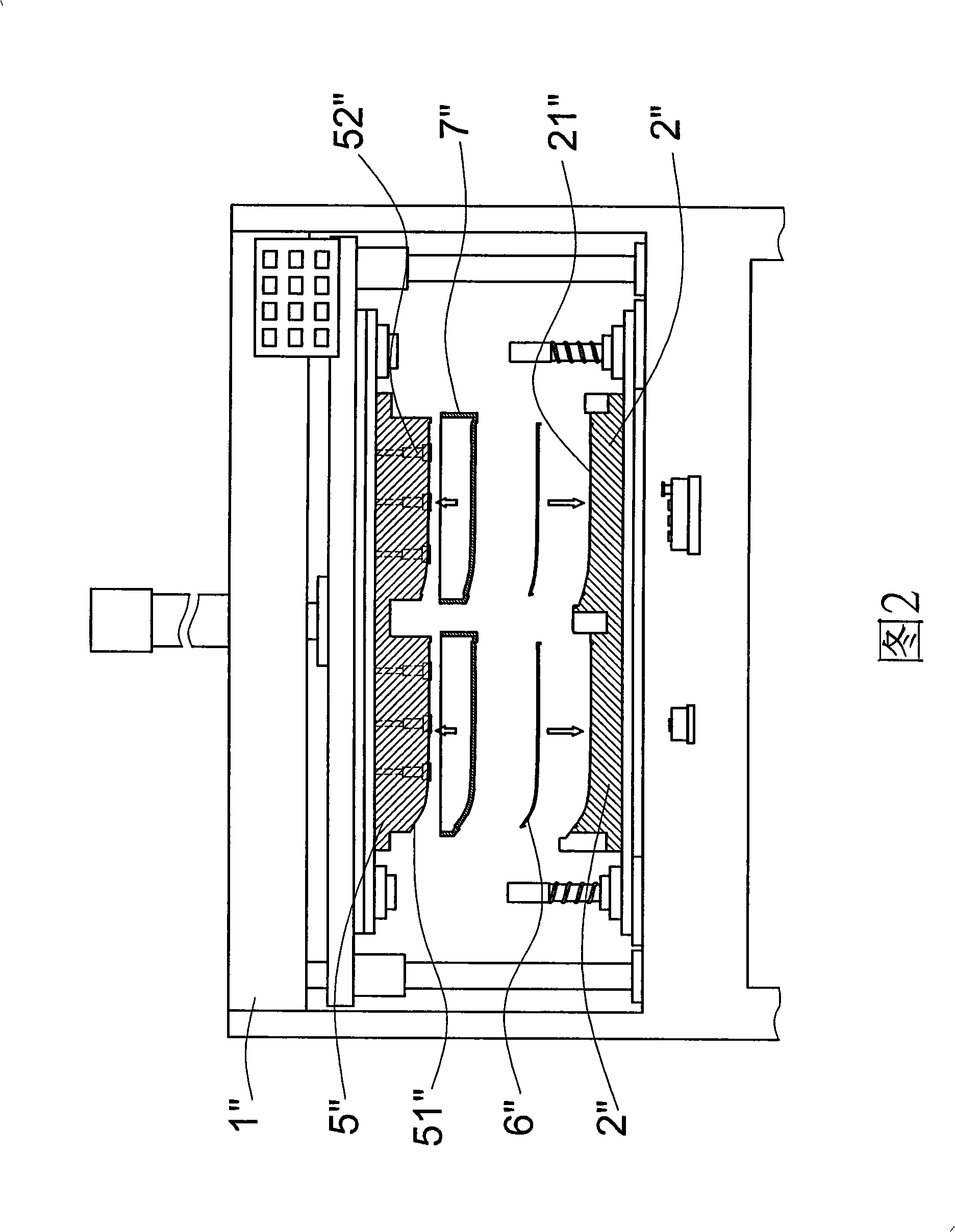

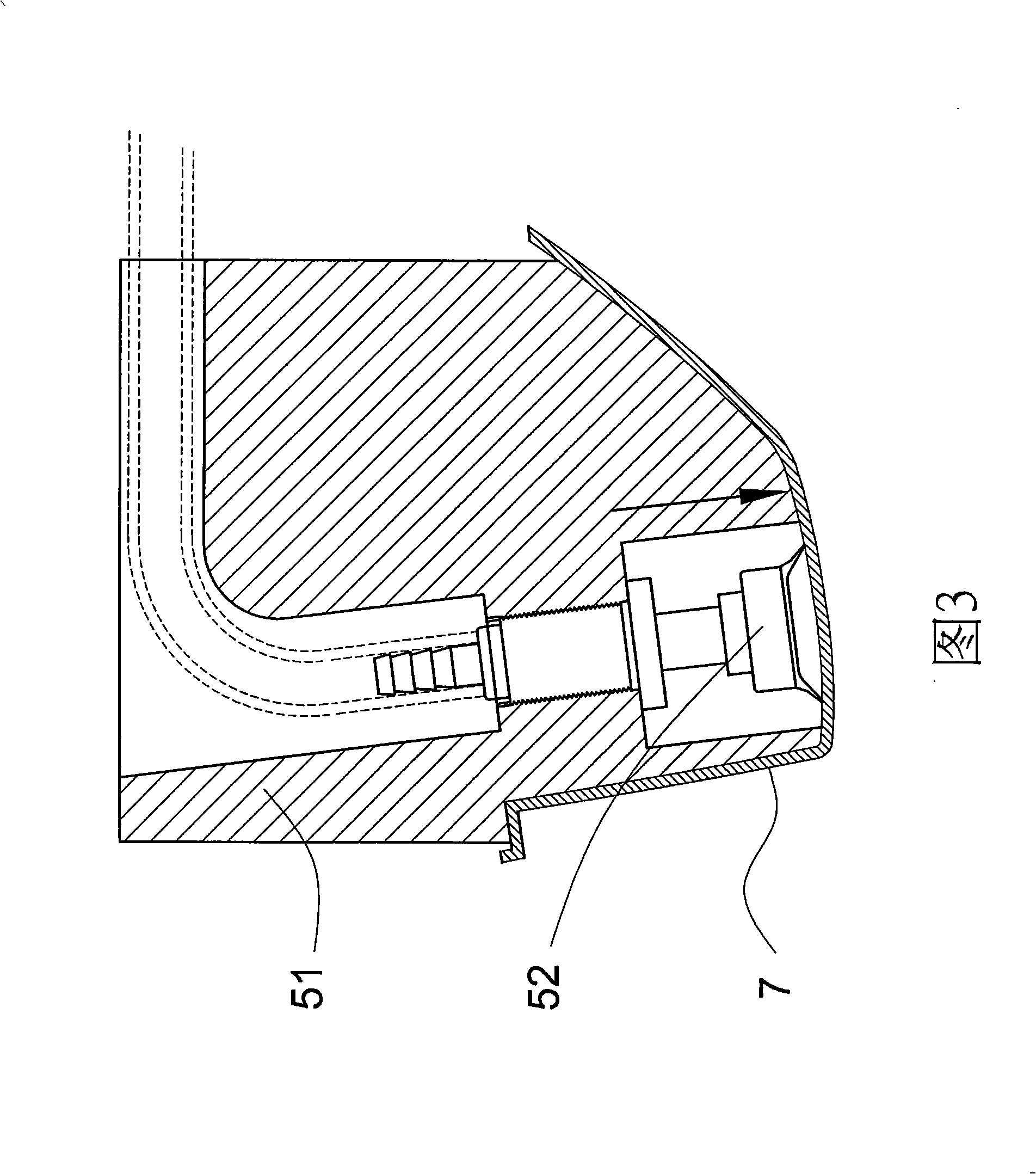

[0034] The present invention is a method and device for bonding the adhesive surface of a molded part. Please refer to Figure 1 to Figure 6. The method for bonding the adhesive skin includes preparing materials, placing the skin on the mold, and absorbing the molded part. Attaching steps on the mold, pressing and ejection of the finished product, for pasting the skin 6” on the surface of the molded part 7”;

[0035] And about the preferred embodiment of skin bonding of the present invention, then please further cooperate with referring to the bonding device of Fig. 2, and described bonding device is to be provided with an upper die unit 5 ", lower die unit on a machine platform 1 ". 2", the lower mold unit 2" has a mold cavity 21" for placing the skin 6".

[0036] The machine 1" is provided with an upper mold unit 5" that can slide up and down relative to the lower mold unit 2" above the lower mold unit 2", and the upper mold unit 5" has several punches 51 corresponding to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com