Easy hydraulic extraction machine

A mining machine and hydraulic technology, applied to a simple hydraulic mining machine. It can solve the problems of lack of mechanical equipment, high price and high unit energy consumption in mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

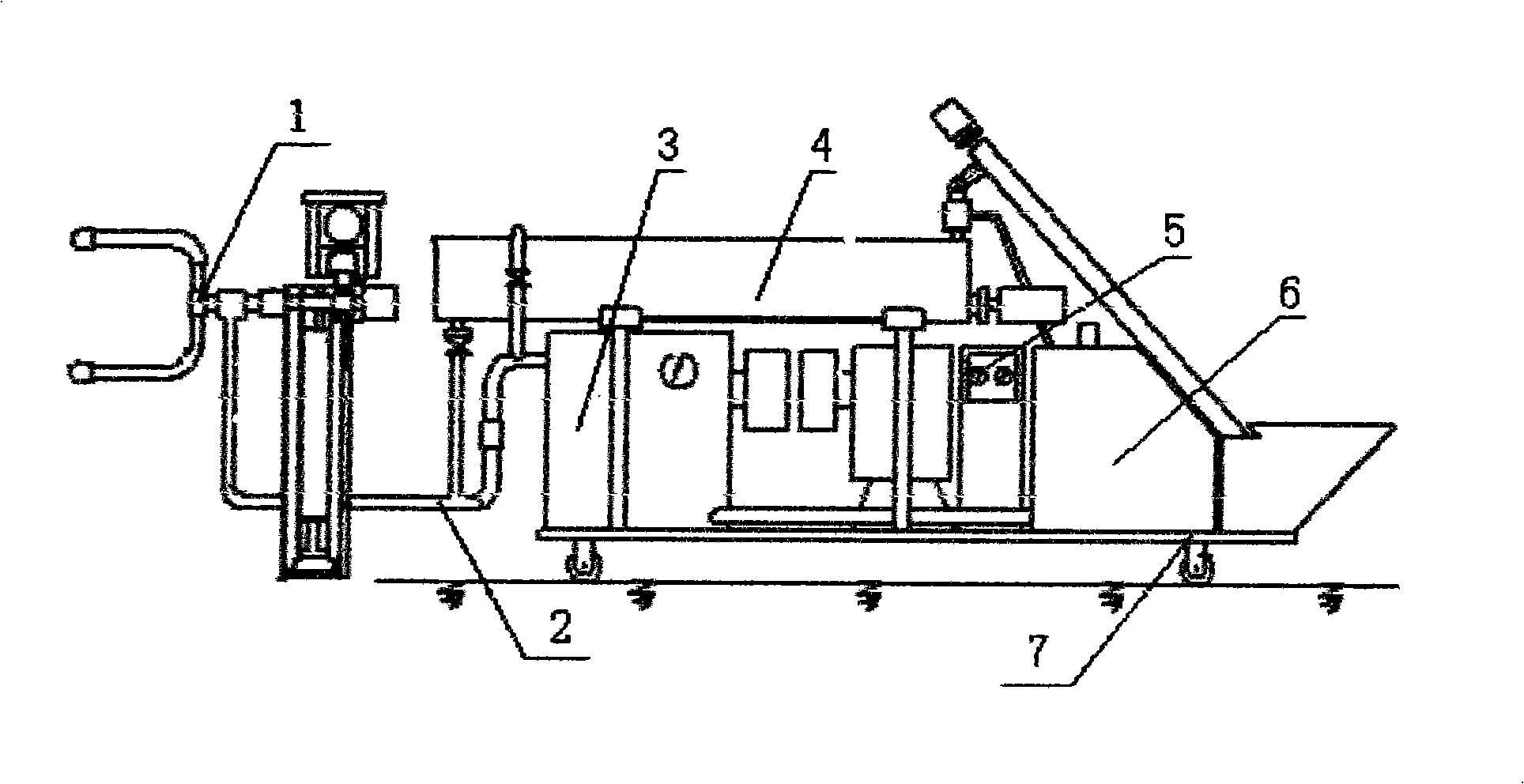

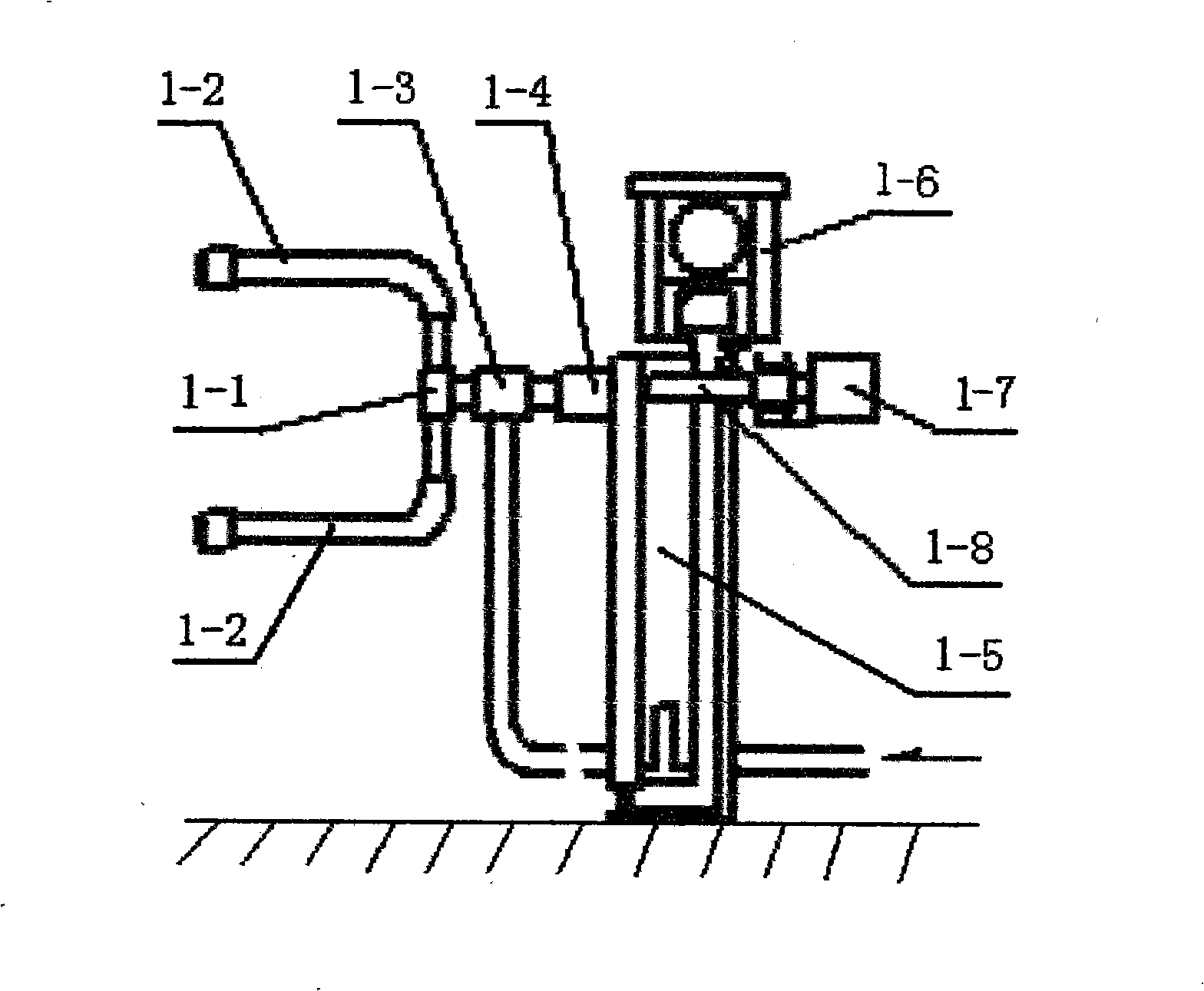

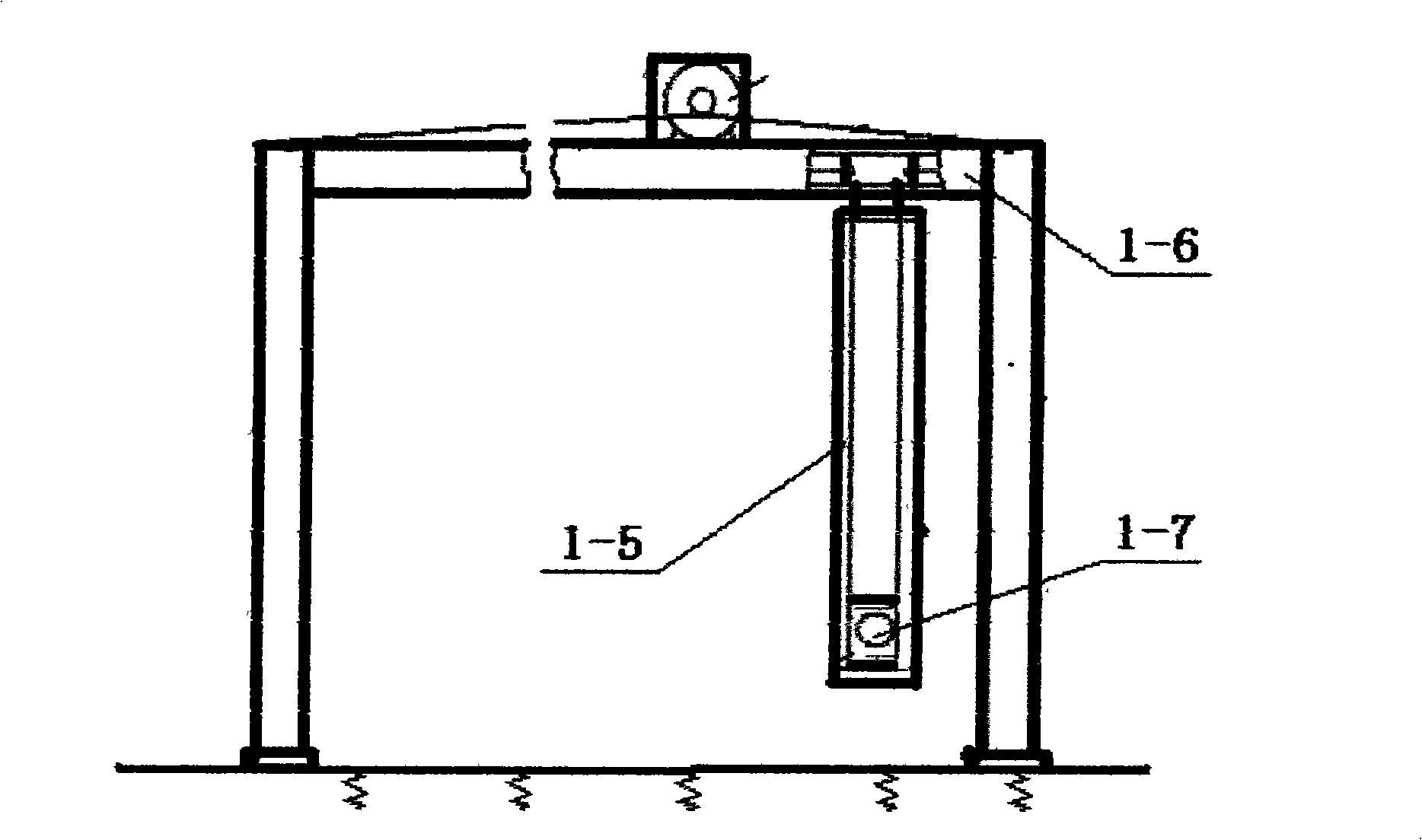

[0028] Example figure 1 As shown, the simple hydraulic mining machine is composed of a hydraulic cutter movement mechanism 1, a water-sand mixing manifold 2, a high-pressure water pump unit 3, a front-mixing abrasive continuous mixing device 4, a power monitoring system (control console 5), and waste water The recycling system 6 is composed of a self-propelled flatbed vehicle 7 and a simple ore breaking tool 8; its self-propelled flatbed vehicle 7 is fixed with a high-pressure water pump unit 3, a control console 5, a waste water recovery and treatment system 6, and a front-mixing abrasive continuous mixing device 4 The support frame is fixedly connected with the self-propelled flatbed vehicle 7, and the self-propelled flatbed vehicle 7 and the front-mixing abrasive continuous mixing device 4, the high-pressure water pump unit 3, the control console 5, and the waste water recovery and treatment system 6 constitute the main body of the mining machine, which is convenient for min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com