Four-cylinder spherical internal combustion engine main body mechanism

An internal combustion engine, spherical technology, applied in the direction of internal combustion piston engines, combustion engines, machines/engines, etc., can solve the problems of high sealing and lubrication conditions, not widely used, difficult processing and control, etc., to achieve the elimination of piston straight lines Reciprocating motion, broad market application prospects, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

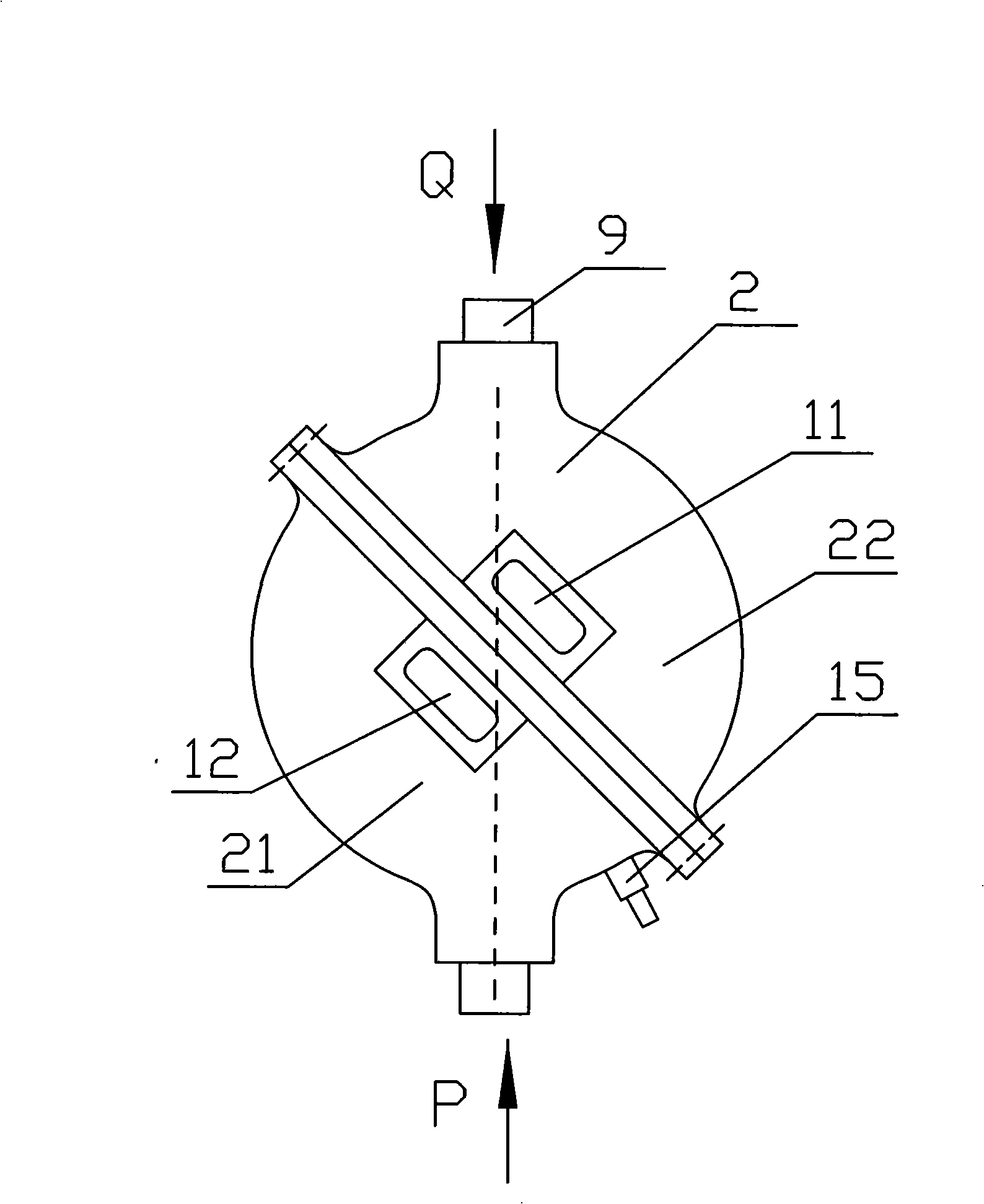

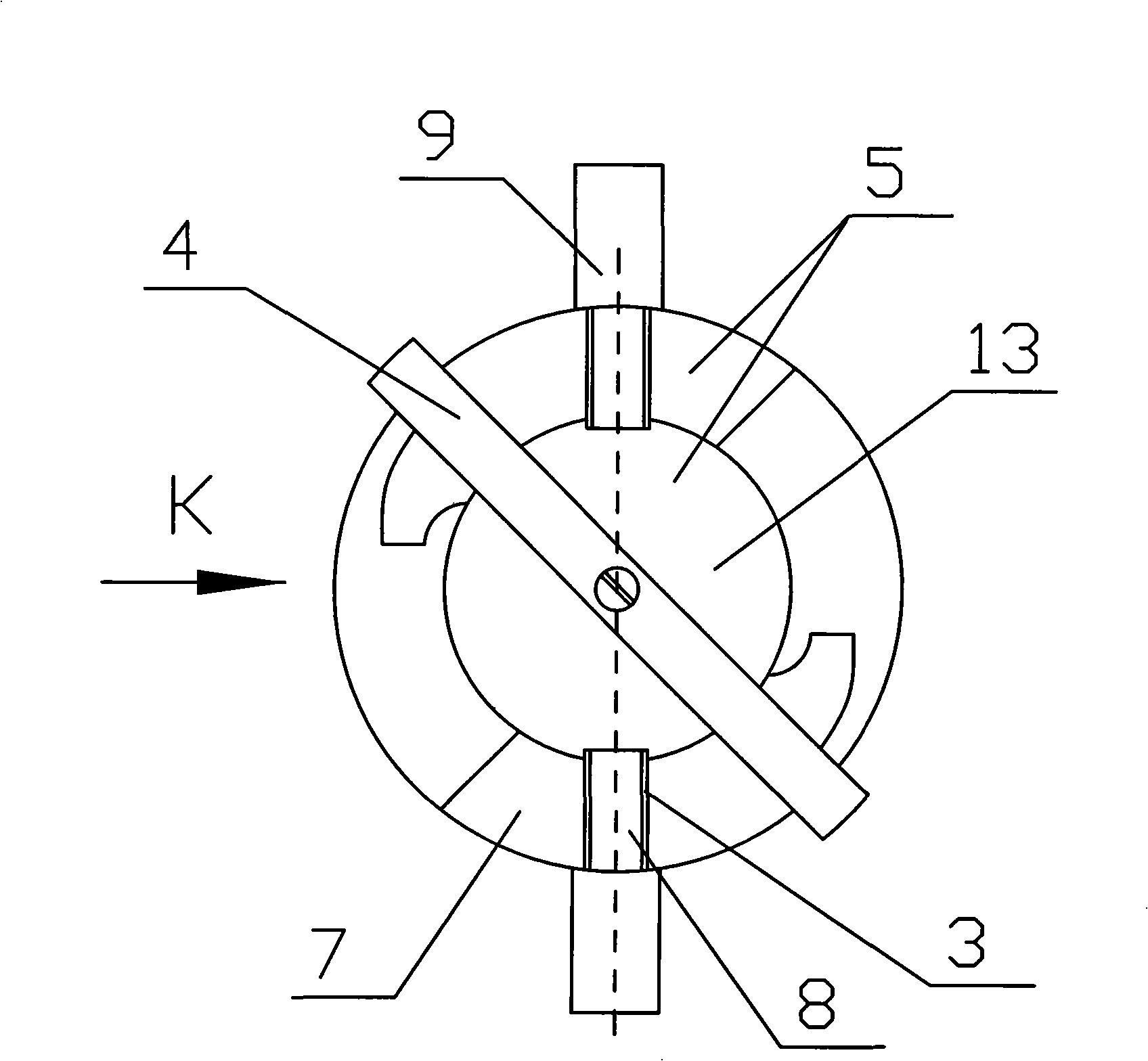

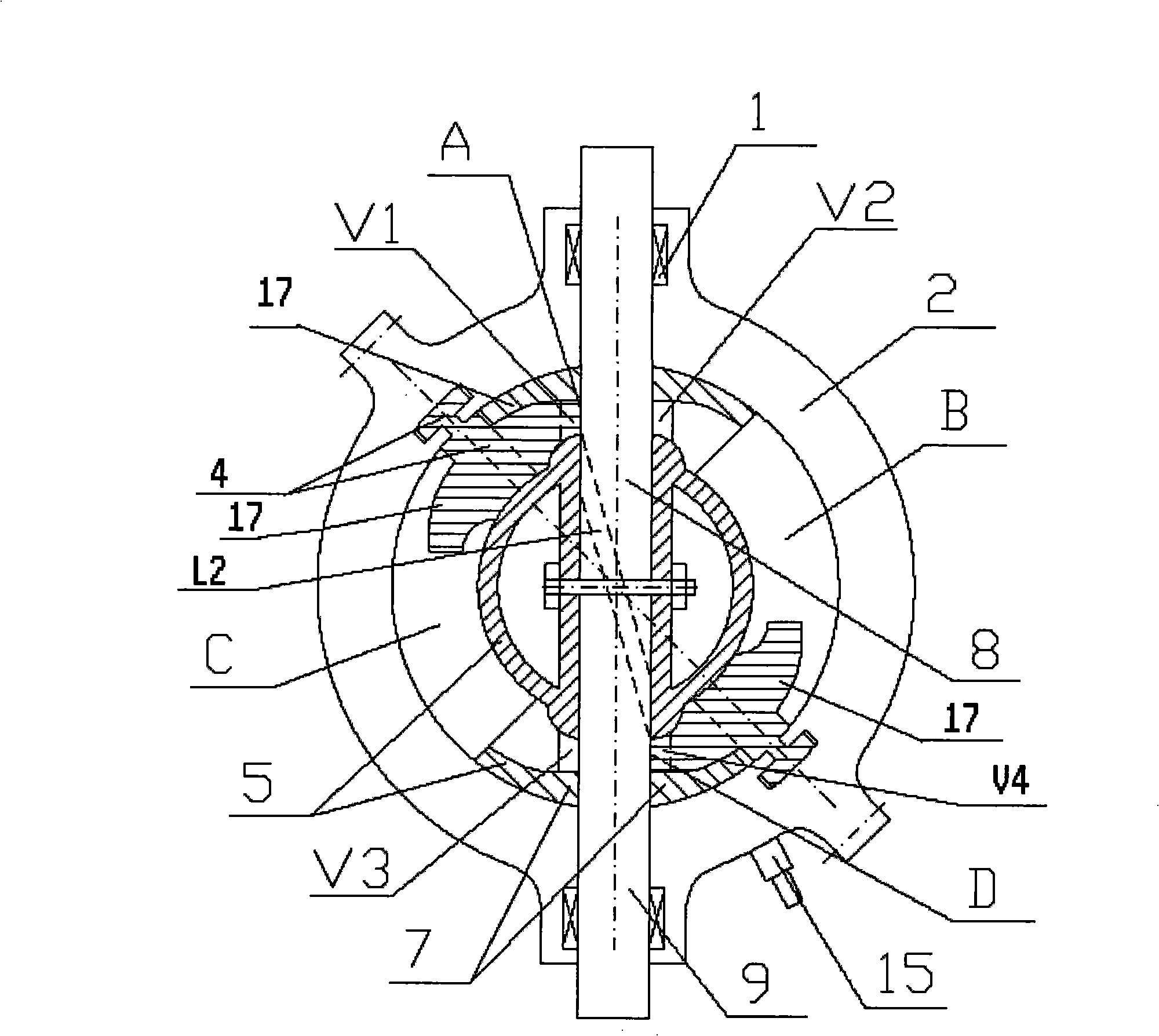

[0016] The main mechanism of the four-cylinder spherical internal combustion engine of the present invention includes a spherical casing 2 with main journal bearing seats 1 at both ends. In this embodiment, the spherical casing 2 is composed of a left half casing 21 and a right half casing 22 , the spherical casing 2 is provided with a septum ring 4 which forms an angle of 35 to 55 degrees with the center through holes of the main journal bearing seats 1 at both ends and can rotate relative to the spherical casing 2. The septum ring 4 4 The middle part of the body is provided with a spherical-like rotating piston 5 with a spherical top surface 13 on the upper and lower parts. The two sides of the rotating piston 5 are symmetrically connected with piston petals 7 with a spherical surface on the outer surface, so that the air chambers on both sides of the septum ring 4 form four working air chambers A, B, C, and D. The spherical casing 2. The upper or lower part corresponds to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com