Frame of heat exchanger

A technology of heat exchangers and tube heat exchangers, which is applied in the field of serpentine tube heat exchangers and can solve problems such as distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the following, reference is made to the corresponding drawings, wherein like reference numerals designate like elements throughout the different drawings.

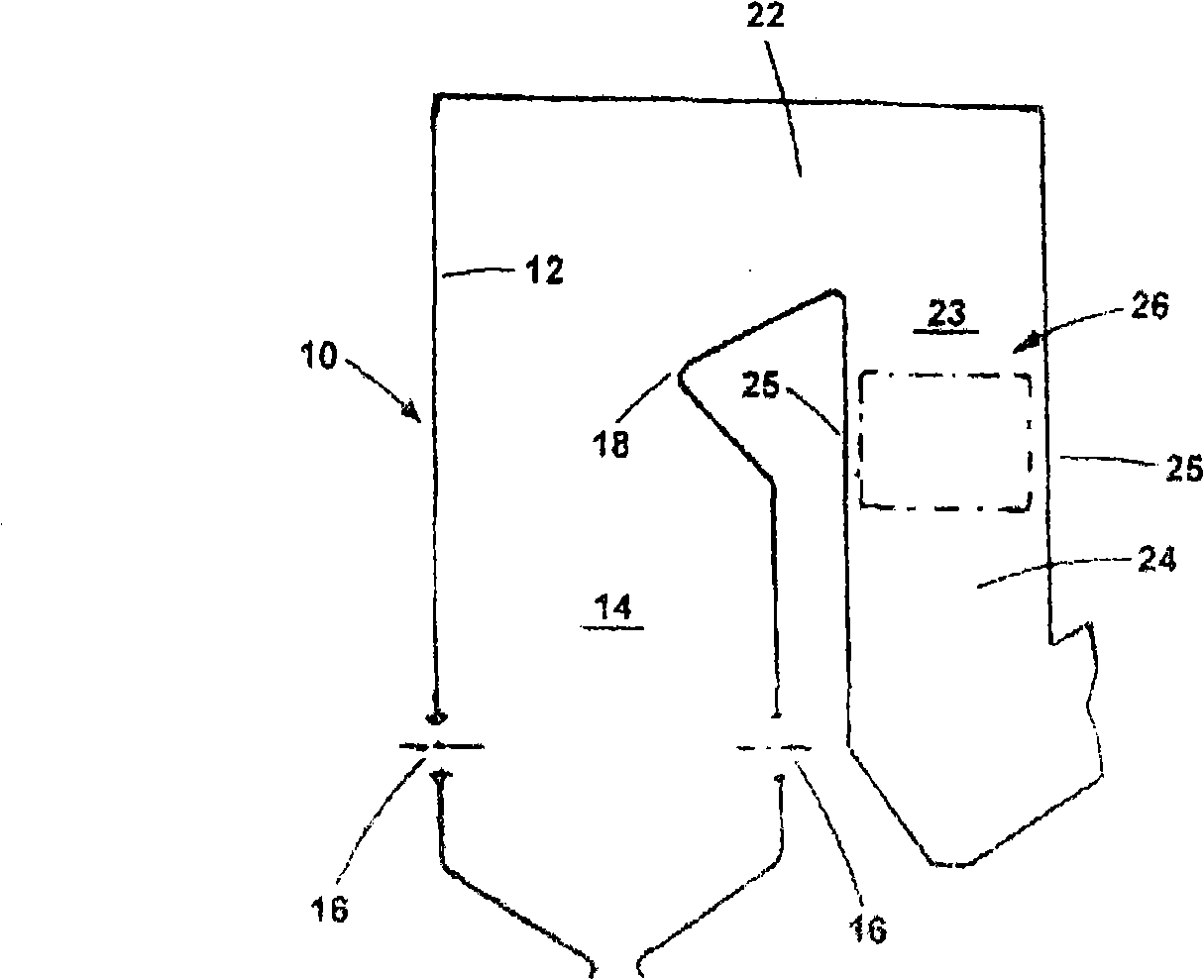

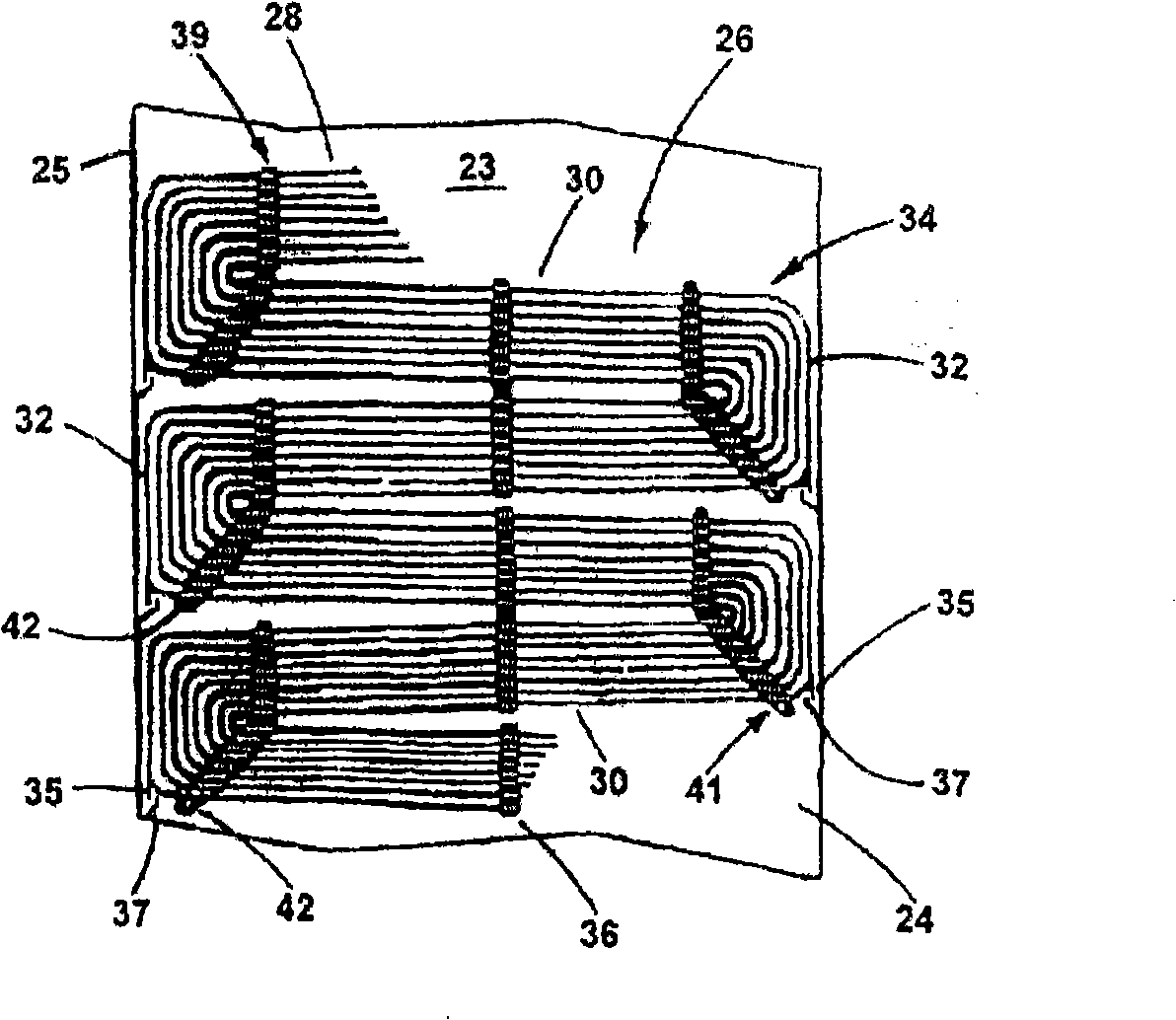

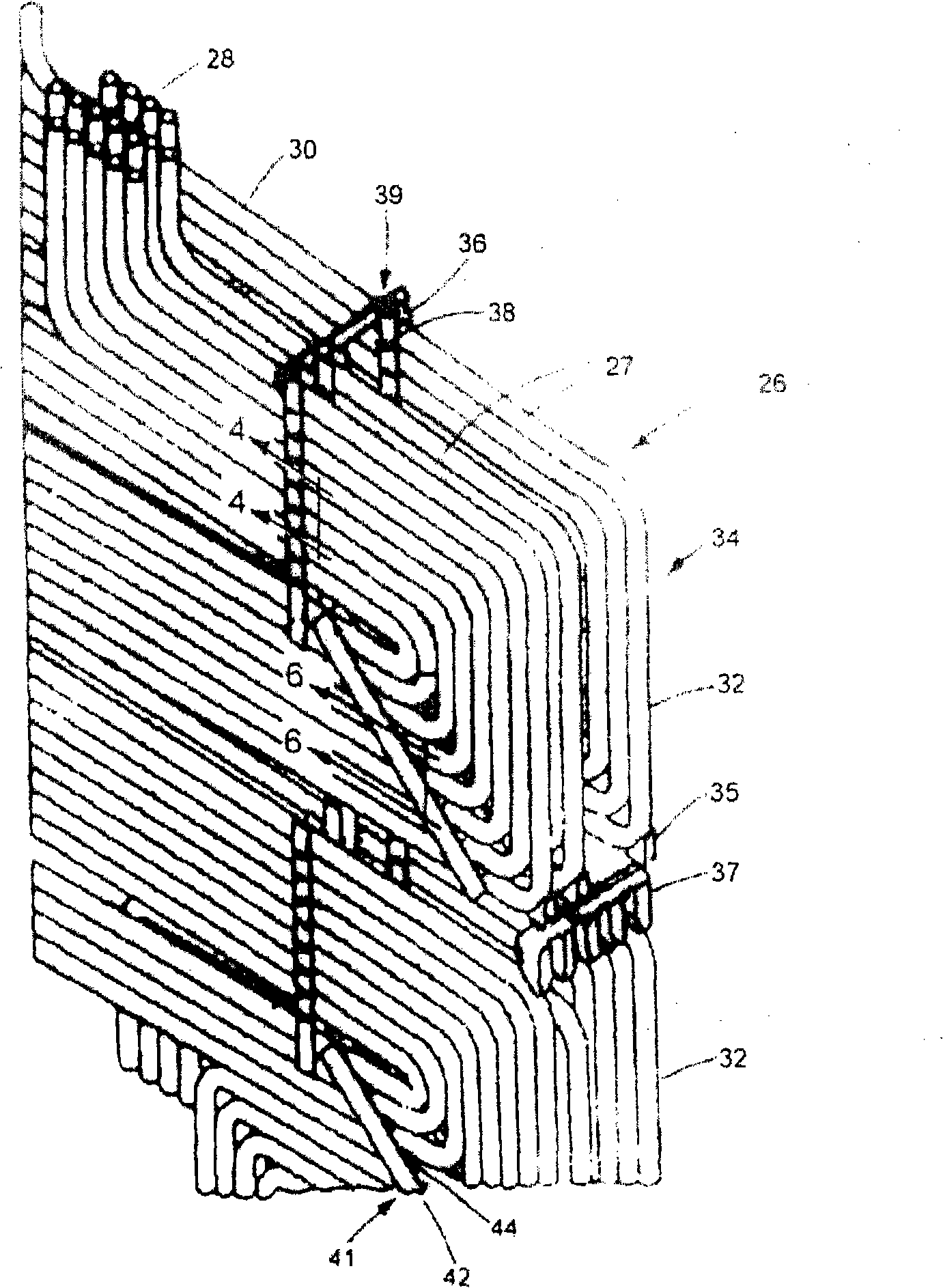

[0018] refer to figure 1 , figure 1 Shown is a steam generator 10 comprising water-cooled tube walls 12 defining a furnace cavity or combustion space 14 to which a fuel and air mixture is provided by a burner as indicated at 16 . After the combustion in the furnace chamber 14 is completed, the hot gas flows upwards and near the convex portion 18 of the furnace chamber, then crosses the horizontal portion 22 of the convection channel 23, and from there passes down the vertical portion 24 of the convection channel 23, vertically Section 24 is delimited by walls 25 and includes a heat exchanger such as a main superheater 26 . Typically, the gas leaving the vertical portion 24 of the convection channel 23 flows through a not shown air heater, from there through a not shown gas cleaning system, and then is discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com