Device and method for the layered production of a three-dimensional object from a powdered constituent

A technology of three-dimensional objects and powder materials, which is applied in the directions of processing and manufacturing, manufacturing tools, additive manufacturing, etc., and can solve problems such as dissatisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

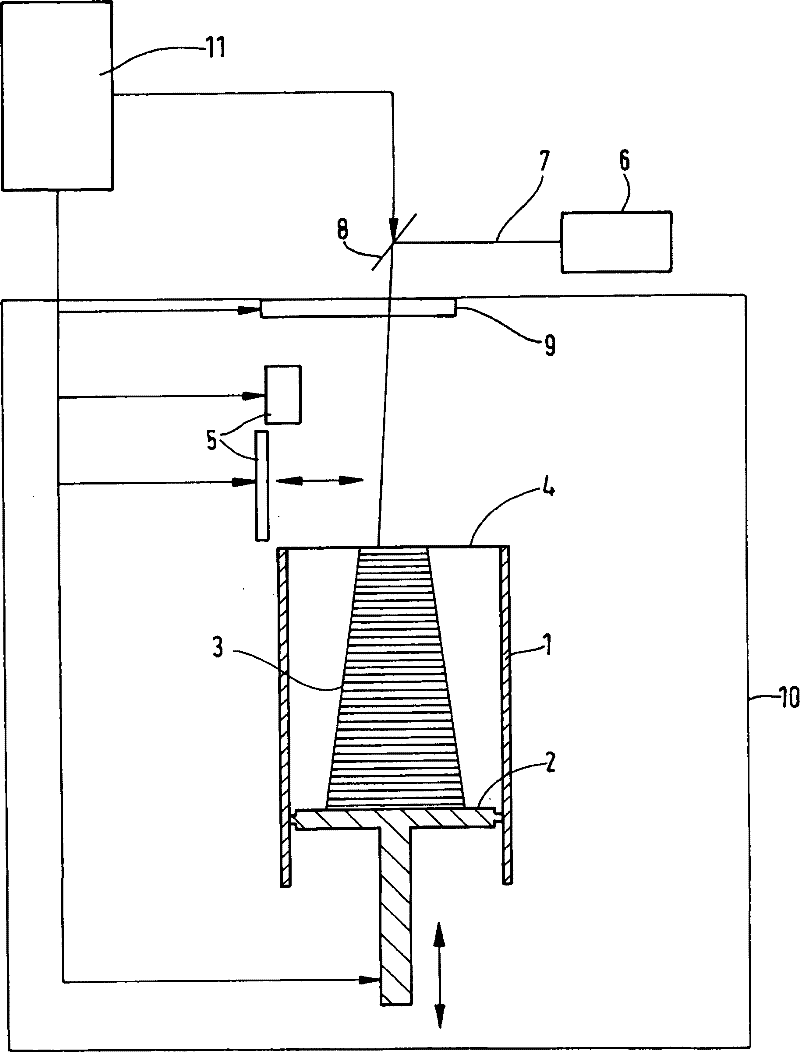

[0034] exist figure 1 The laser sintering system shown in FIG. 2 has an upwardly open container 1 with a vertically movable carrier 2 inside it, which carries an object 3 to be formed and defines a production area. The carrier 2 is adjusted vertically such that each layer of the object to be cured lies on the working plane 4 . An applicator 5 is further provided for applying the powdered manufacturing material curable by electromagnetic radiation. The device further has a laser 6 . The laser beam 7 generated by the laser 6 is deflected by the deflection device 8 onto the coupling window 9 , passes from the coupling window 9 into the processing chamber 10 and is focused at a predetermined point in the working plane 4 .

[0035] A control unit 11 is further provided, by means of which the components of the apparatus are controlled in a coordinated manner to perform the manufacturing process.

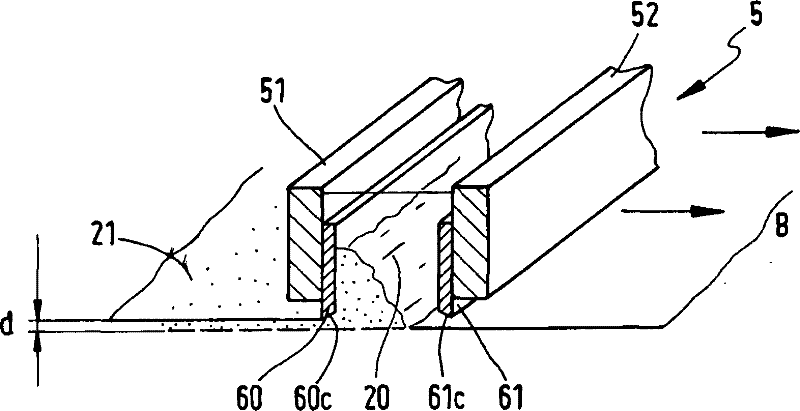

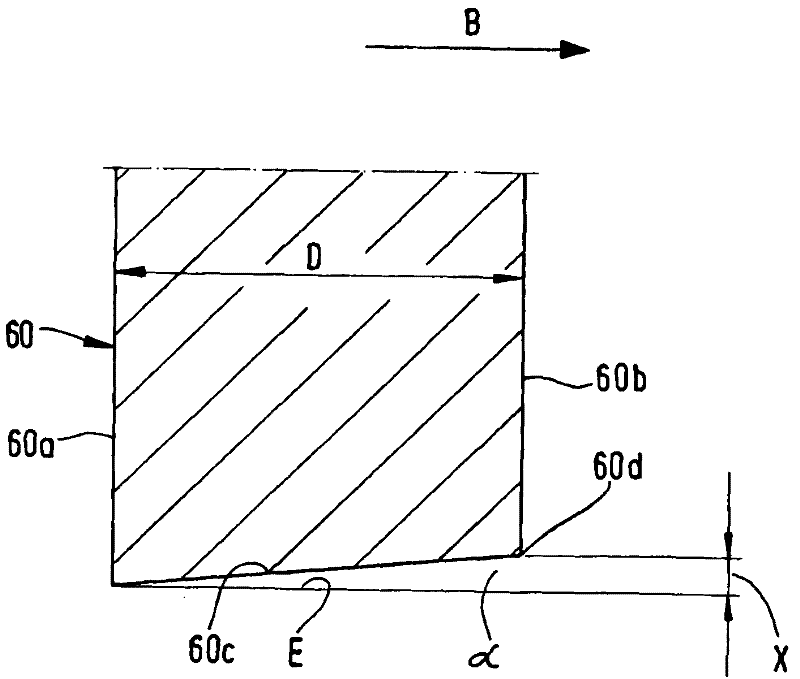

[0036] as in figure 2 As shown in , the applicator 5 has two clamping plates 51 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com