Method for manufacturing ferritic stainless steel slabs with equiaxed grain structures and the ferritic stainless steel manufactured by it

A technology of equiaxed grain and ferrite, which is applied in the manufacture of ferritic stainless steel slabs with equiaxed grain structure and the field of ferritic stainless steel produced by this method, can solve the problem of ambiguity and accuracy of deoxidizer Reduce, do not specify the specific type of deoxidizer, etc., to achieve the effect of excellent formability, improved operation stability, and low wrinkle defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

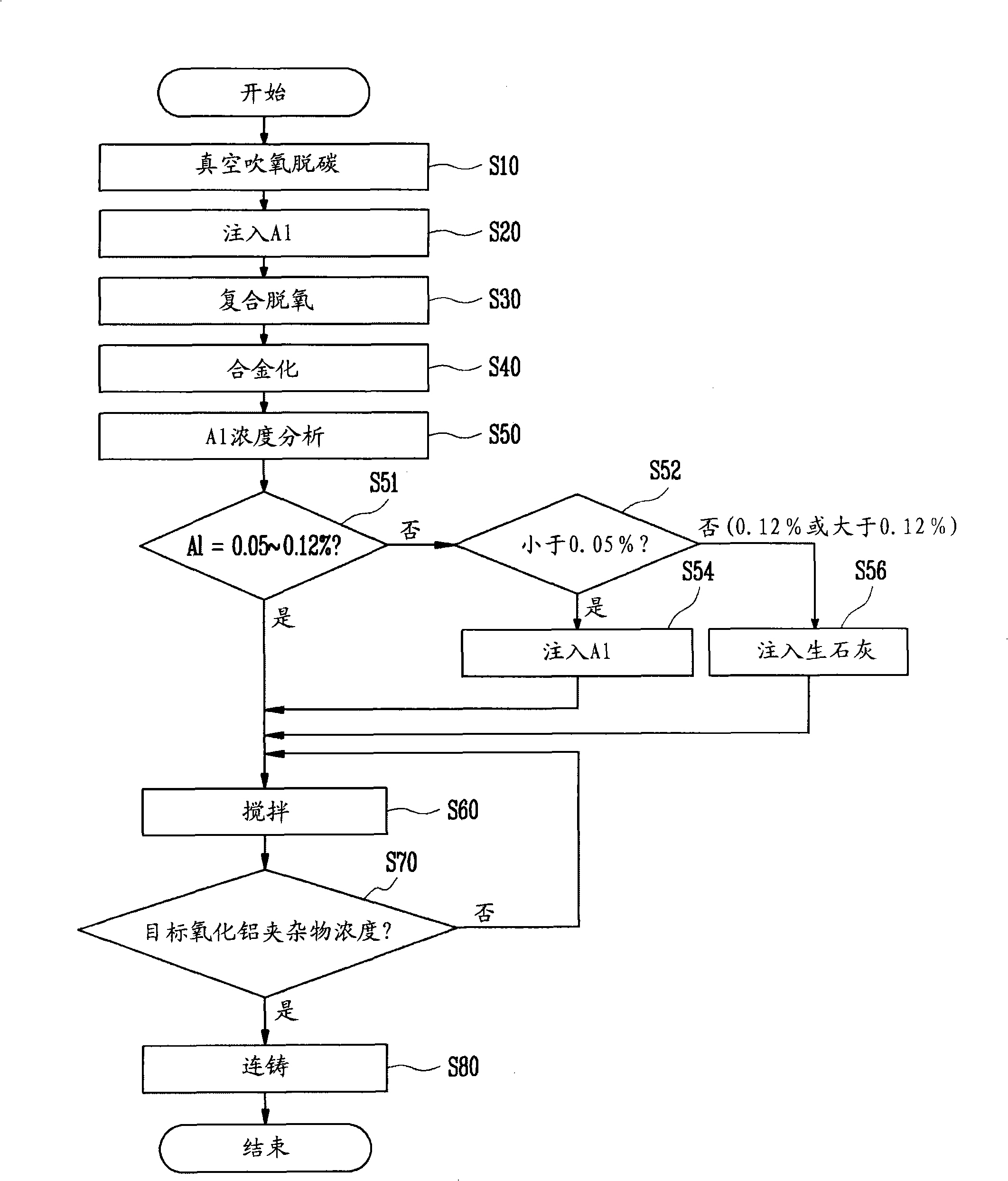

[0027] In order to achieve the object of the present invention, a method for manufacturing a ferritic stainless steel slab with an equiaxed grain structure is provided, the method comprising the following steps: Oxygen blowing, so as to carry out oxygen blowing decarburization reaction; in order to reduce Cr 2 o 3 , injecting Al into the molten steel that has undergone the oxygen blowing decarburization reaction; 2 o 3 And inject deoxidizer into the molten steel that injects Al to carry out compound deoxidation; Carry out alloying process by injecting alloying metal into molten steel; Judgment for the first time, wherein, judge for the first time by analyzing the concentration of Al in molten steel To judge whether the concentration of Al is within the range of the set value; if the concentration of Al meets the set value, then use inert gas to stir the molten steel, and make a second judgment, wherein the second judgment is used to judge the final molten steel Whether the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com