Electric machine double-layer disconnecting means of profiled steel sheet machine

A technology of cutting device and profiled steel plate, which is applied in the direction of shearing device, shearing machine equipment, metal processing equipment, etc., can solve the problems affecting the appearance quality of the plate, difficult to adjust the pressure of the hydraulic station, easy oil leakage of the hydraulic pipe, etc., and achieve structural Compact, efficiency-enhancing, cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

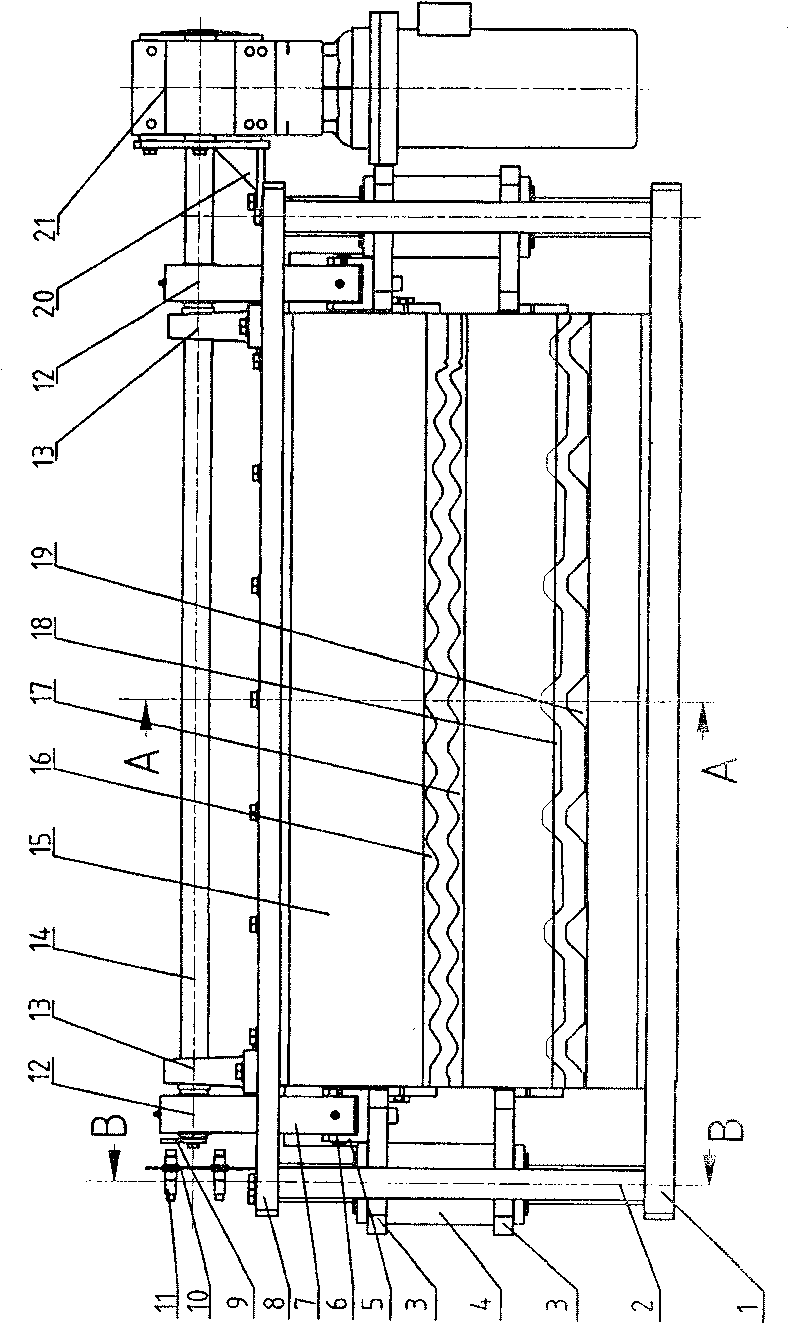

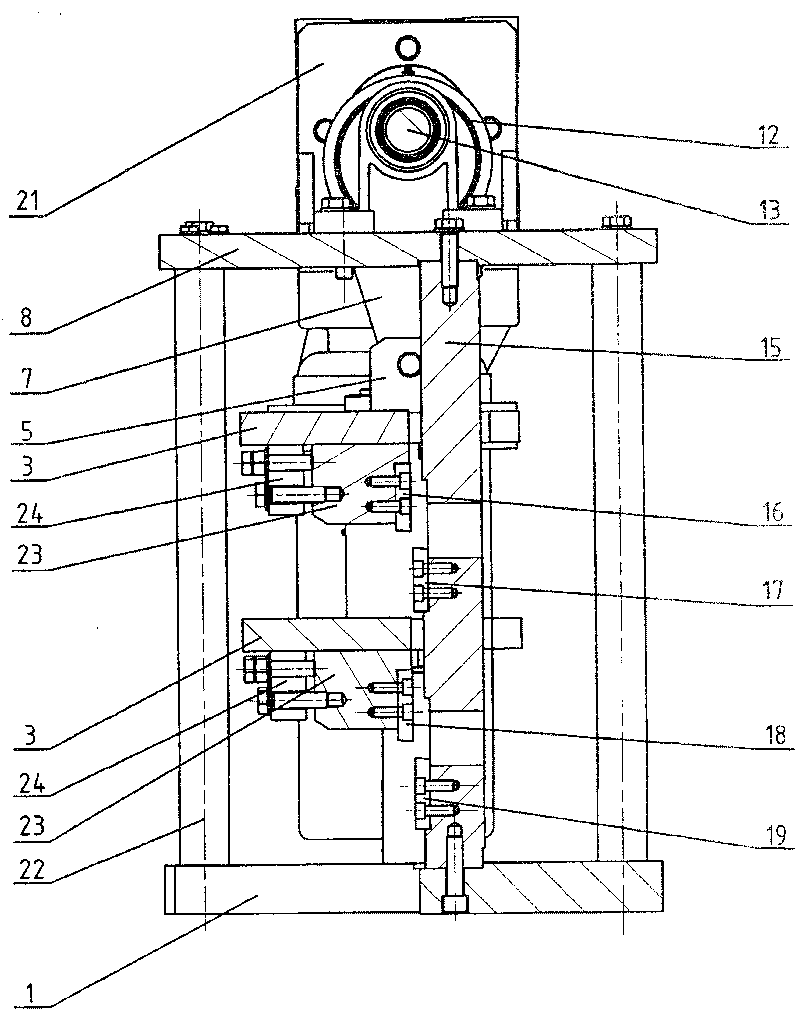

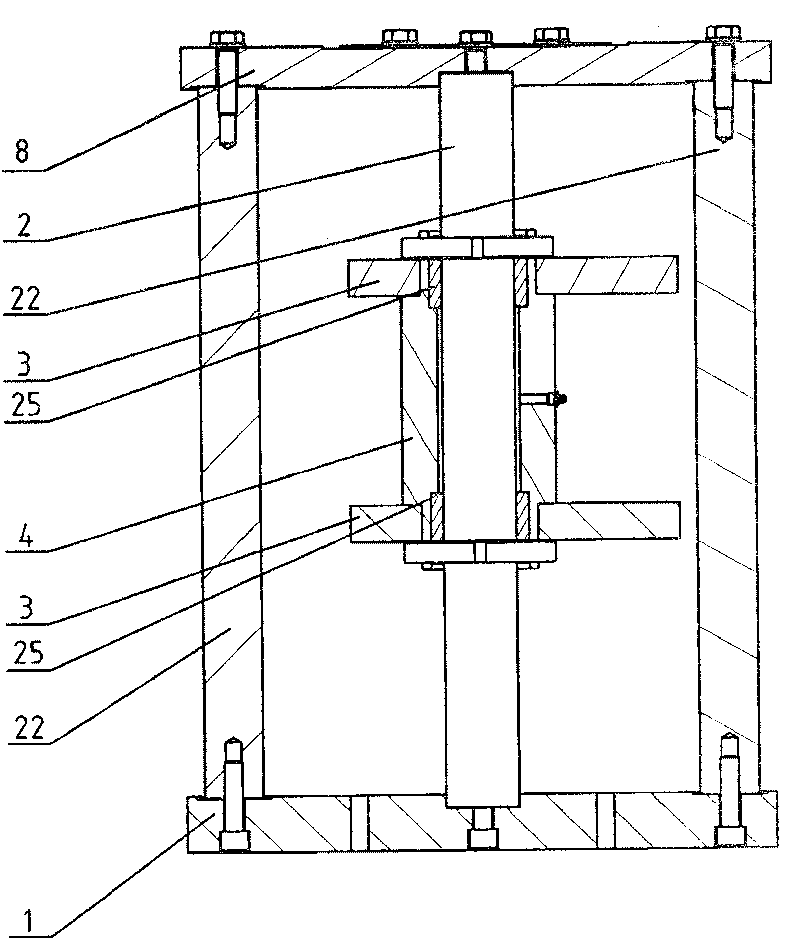

[0018] The present invention is mainly fixed on the column 22 on the lower mounting plate 1 and the upper mounting plate 8 at both ends, the knife plate mounting frame 15, the guide rod 2, and places the vertical bearing block 13 with the transmission shaft 14 at both ends of the upper mounting plate 8. , the motor 21 placed at one end of the transmission shaft 14, the eccentric wheel 12 with the crank 7 placed on both sides of the transmission shaft 14, the sliding sleeve 4 sleeved on the guide rod 2, and the two ends of the sliding sleeve 4 are respectively equipped with upper cutters 16 and the active plate 3 of the upper cutter 18 on the lower floor, the lower cutter 17 and the upper cutter 19 on the lower floor placed on the cutter plate mounting frame 15, placed on the light control angle seat 10 with the sensor 11 on the upper mounting plate 8, The induction baffle 9 corresponding to the sensor 11 is placed on the eccentric wheel 12, the oil-free lubricating bushing 25 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com