Working head of device for processing surface of stone

A work head and stone technology, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of inability to increase production capacity, high cost, high defect rate, and achieve better three-dimensional effect, simple structure, and processing. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

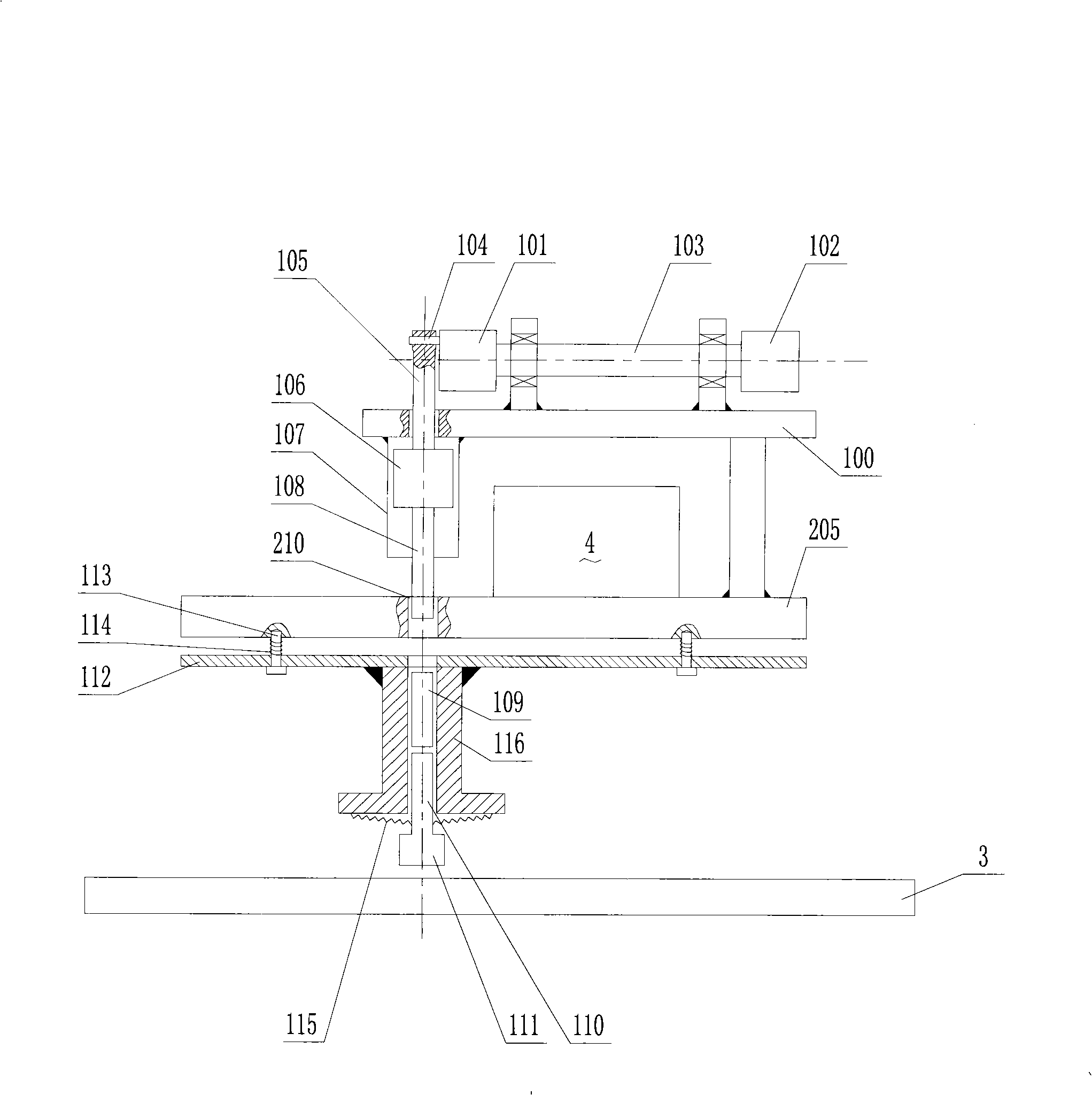

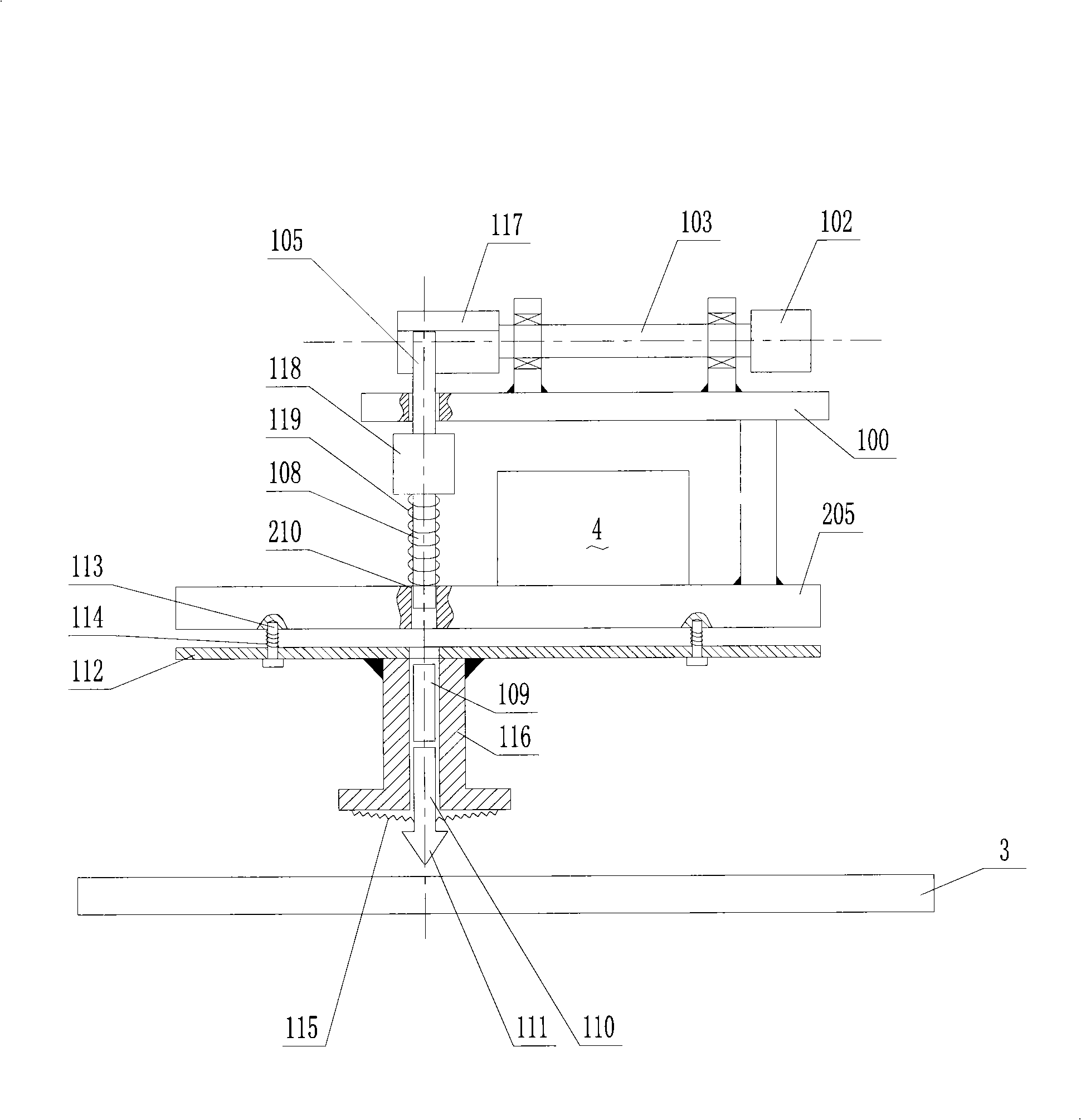

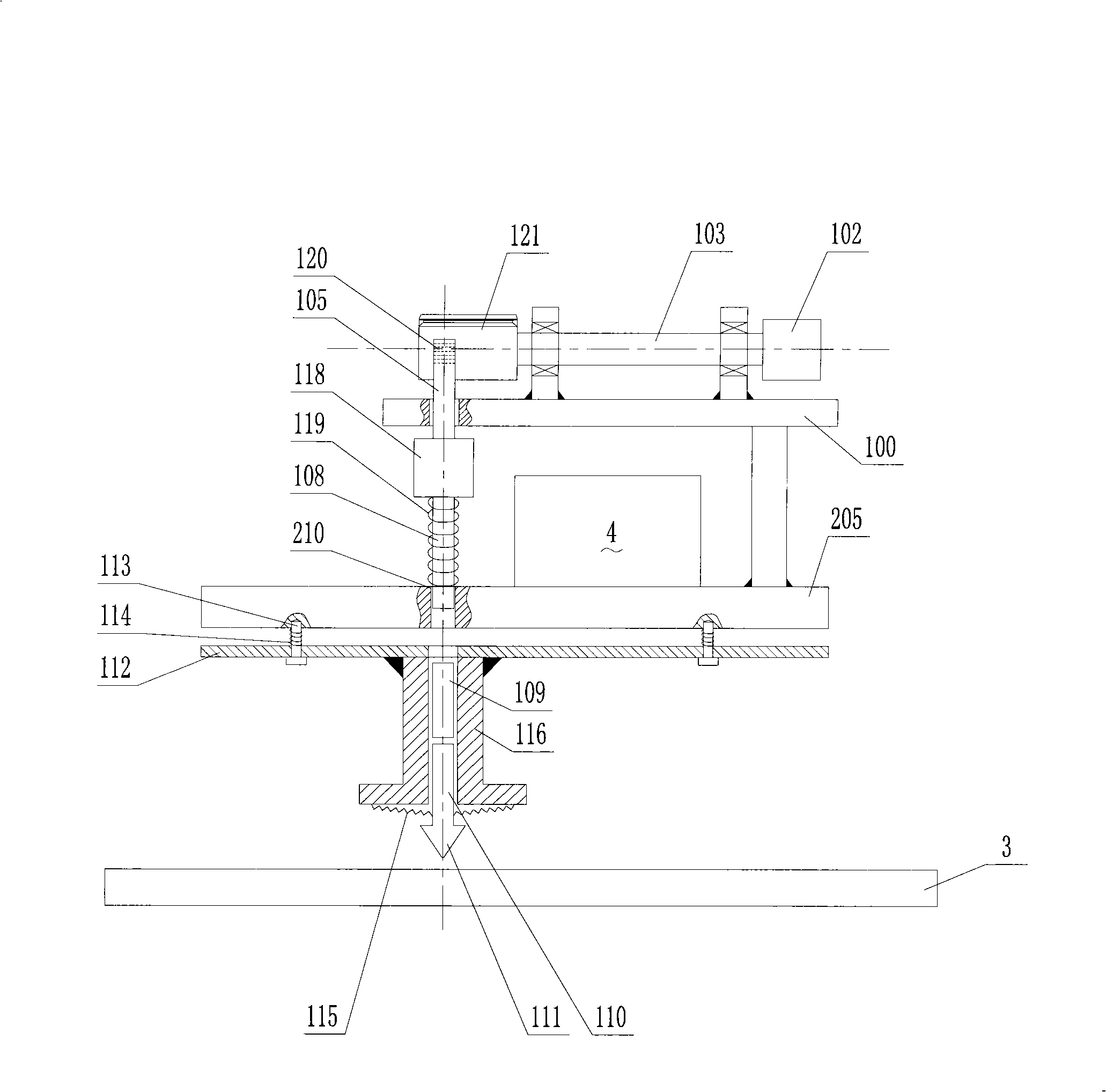

[0039] The invention discloses a working head of a device for processing the surface of stone (including granite or marble, etc.), the purpose of which is to process anti-skid grooves or other patterns, patterns, etc. on the surface of the stone, including a reciprocating mechanism driven by a motor 4 , a cutter, and a reset piece connected to the cutter, the reciprocating mechanism intermittently impacts the cutter for processing the stone surface, and the reset piece enables the cutter to return to the initial state after completing one chisel downward. Location. The reciprocating mechanism and the cutting knife are matched on a base 205, and the base 205 is provided with a base hole 210 that runs through. The principle of the present invention is to use the reciprocating mechanism to pass through the base hole 210, intermittently impact the cutter for processing the stone surface, and drive the cutter to cut and chisel the stone surface intermittently, leaving incisions on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com