Soda-lime silicate plate-like glass and manufacturing method thereof

A technology of soda lime silicate and plate glass, which is applied in the manufacture of the above-mentioned glass composition, the manufacture of glass plates for solar cells, and the manufacture of soda lime silicate plate glass, can solve the problem that the tendency of crystallization is large and difficult to overcome. , yield decline and other problems, to achieve the effect of reducing melting temperature, reducing coefficient of thermal expansion, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

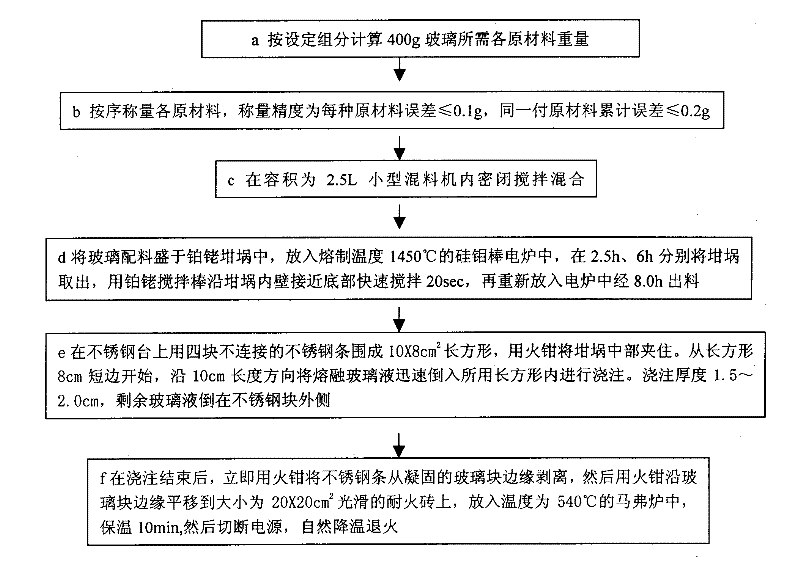

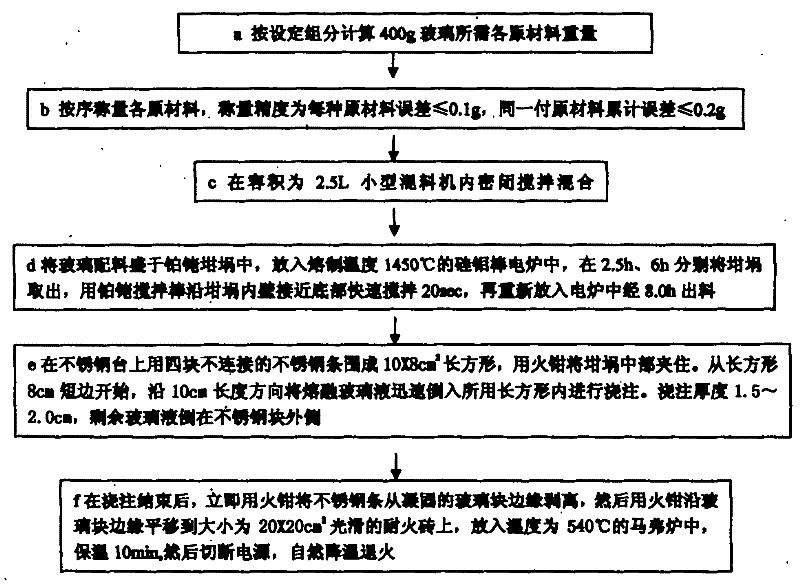

Method used

Image

Examples

Embodiment Construction

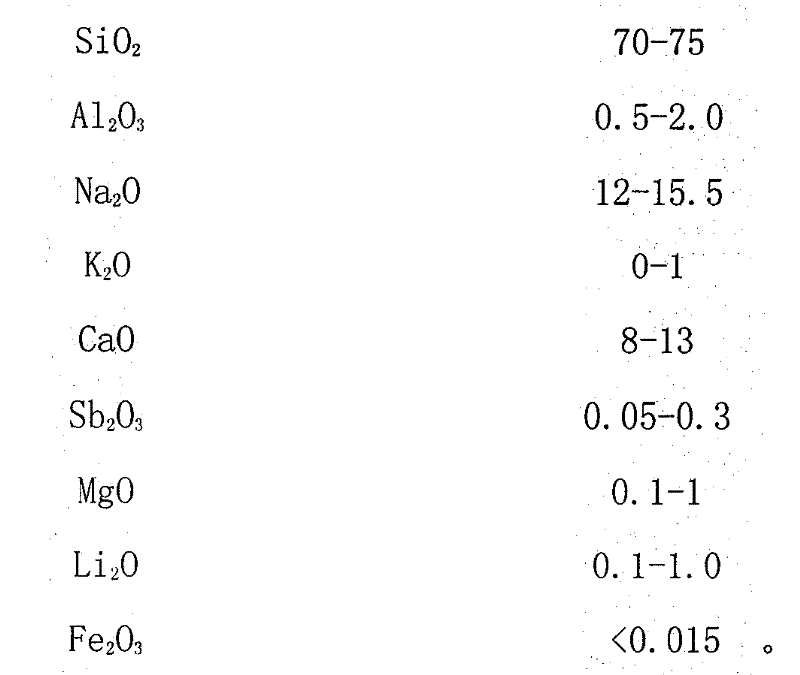

[0021] In the composition of soda lime silica glass, SiO 2 As the main glass network former, it usually contains more Na 2 O, CaO, Al 2 o 3 , and other glass regulators, such as MgO, K 2 O et al. Among these glass components, CaO and MgO have a greater impact on the crystallization performance of the glass, especially the increase in the CaO content usually causes the liquidus temperature of the glass to rise, and a small amount of MgO replacing CaO is beneficial to increase the crystallization resistance of the glass, but Its content must be limited, otherwise it will increase the crystallization tendency of the glass. A small amount of intermediate can repair the broken silicon-oxygen network and improve the anti-devitrification ability of the glass to a certain extent, but it will make the glass difficult to melt.

[0022] In the present invention, various conventional sodium calcium silicate components are optimized, and CaO, MgO, Al 2 o 3 content while introducing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com