Full automatic silt separation apparatus

A fully automatic technology for sediment separation, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve problems such as the inability of hydro-generator units, and achieve the effects of water saving, reliable performance and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

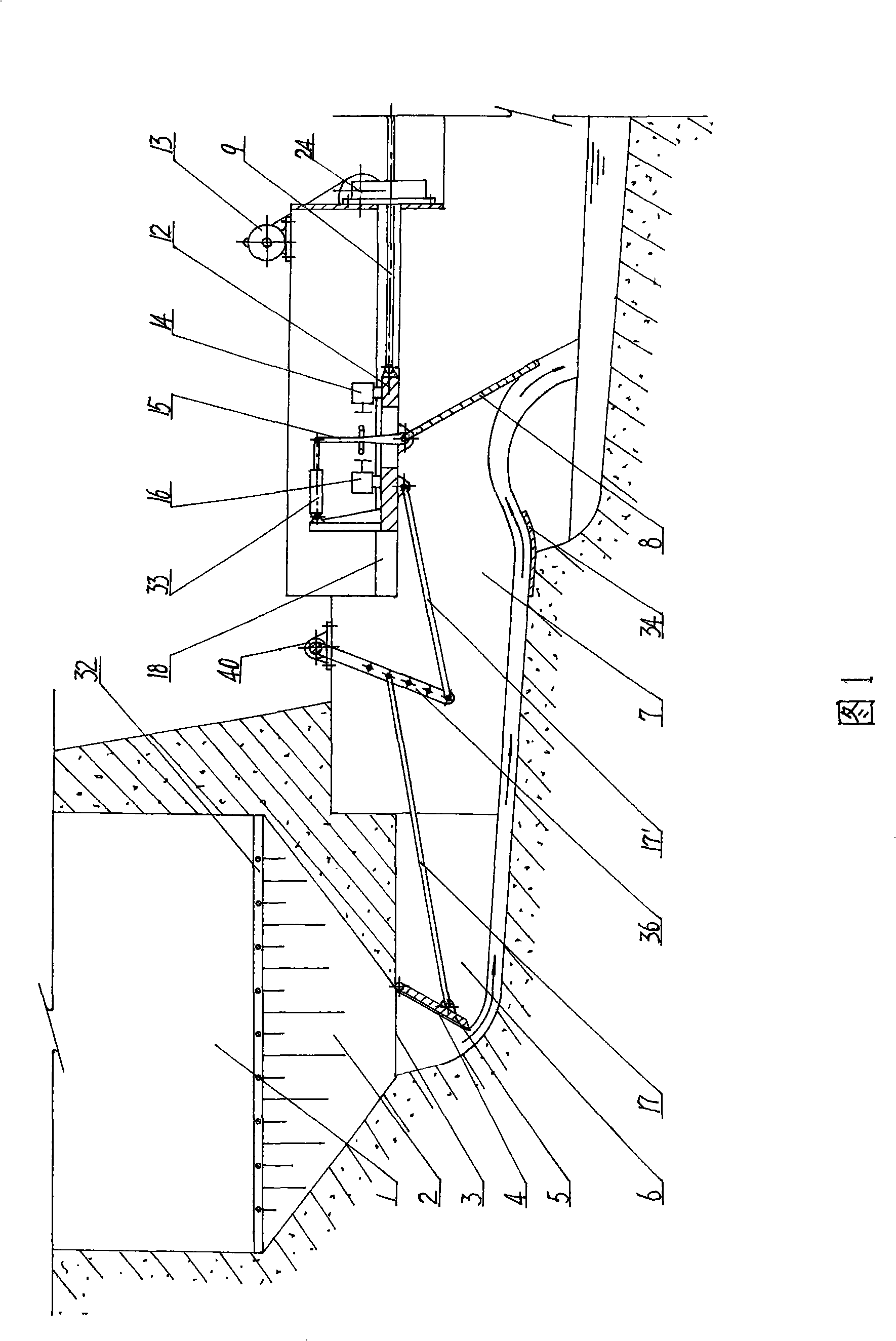

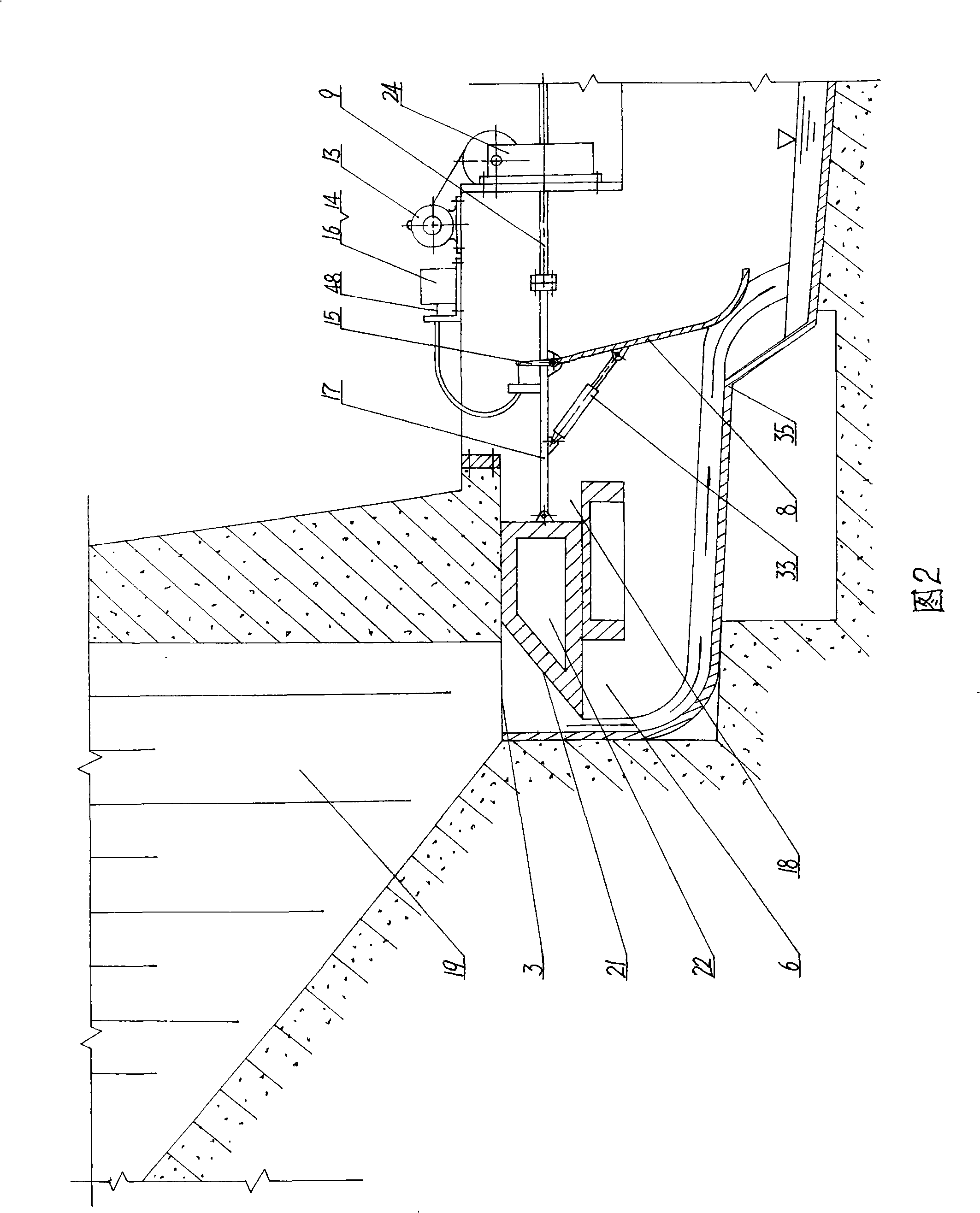

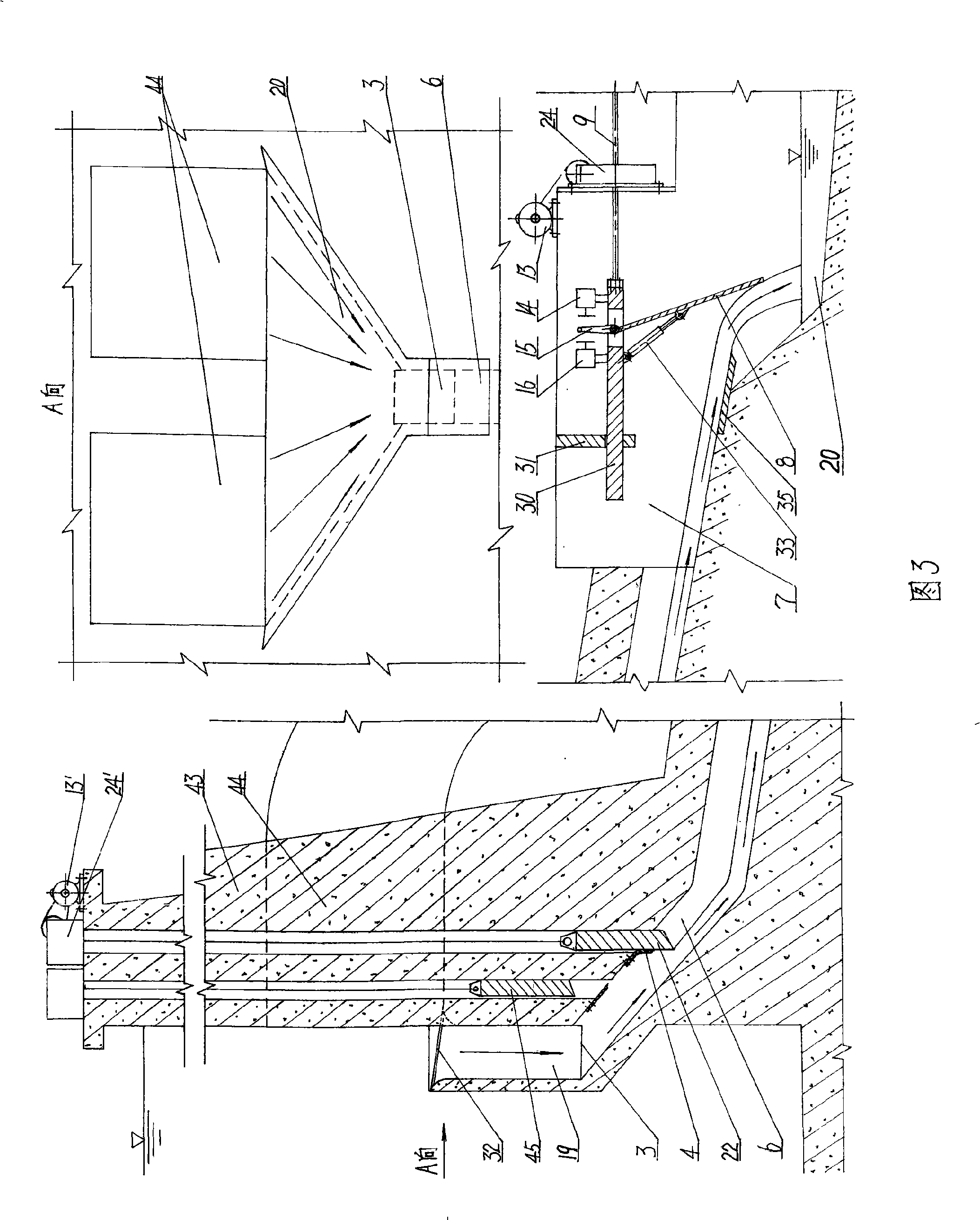

[0032] Figure 1 shows the first embodiment of the present invention.

[0033] As shown in Figure 1: At the bottom of the water diversion channel 1, a trapezoidal groove 2 is extended, and the bottom of the trapezoidal groove 2 is provided with a horizontally arranged rectangular sand outlet 3, and the rectangular sand outlet 3 is connected with a row with a certain slope at the bottom. The outlet end of the sand flow channel 6 and the sand discharge flow channel 6 is connected to the water drop flow channel 7 provided with a ridge 34. A trash rack 32 is installed horizontally on the top surface of the trapezoidal groove 2. A rectangular sand discharging throttle plate 5 is hinged on the edge of the rectangular sand discharging port 3 connected to the top surface of the sand discharging channel 6, and the two sides and hinged ends of the sand discharging throttle plate 5 are provided with seals 4. When the sand discharging throttle plate 5 is hanging down, a driving rod 17 is hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com