Magnetic floating and magnetic moving horizontal fan shaft windmill electric generating apparatus

A windmill power generation and magnetic motion technology is applied in the field of permanent magnet suspension windmill, magnetomotive transmission of windmill torque, and integration of windmill and power generation device, which can solve the problems of reducing economic life, difficult installation, and excessive "tip speed ratio", etc. Achieve the effect of reducing frictional resistance, improving power generation efficiency, and increasing working wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

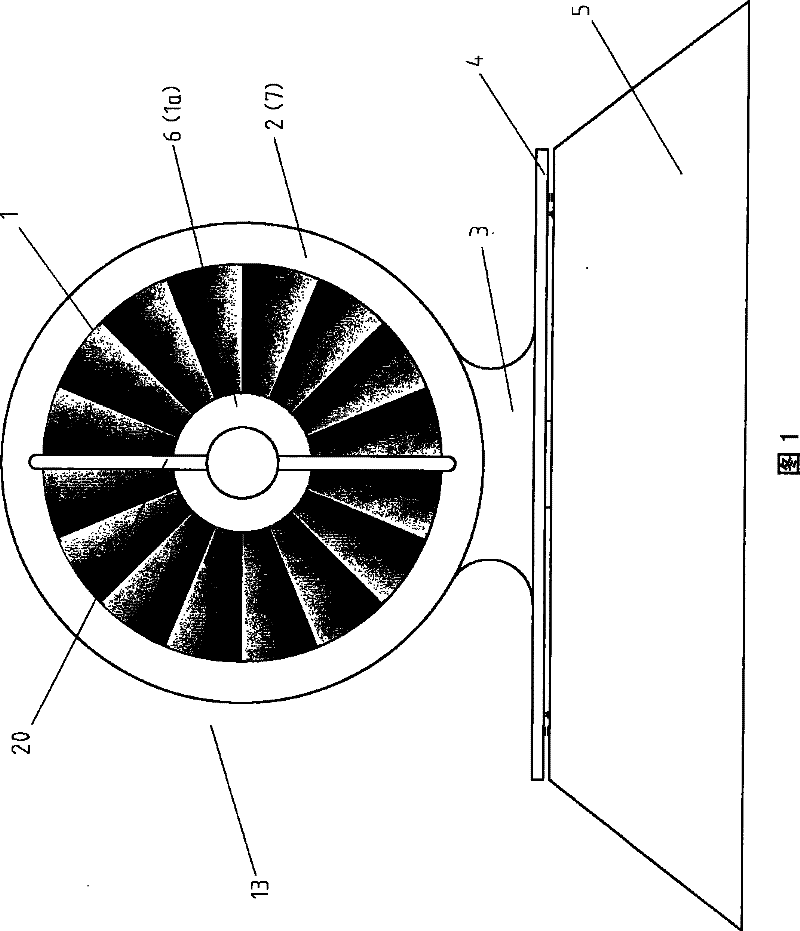

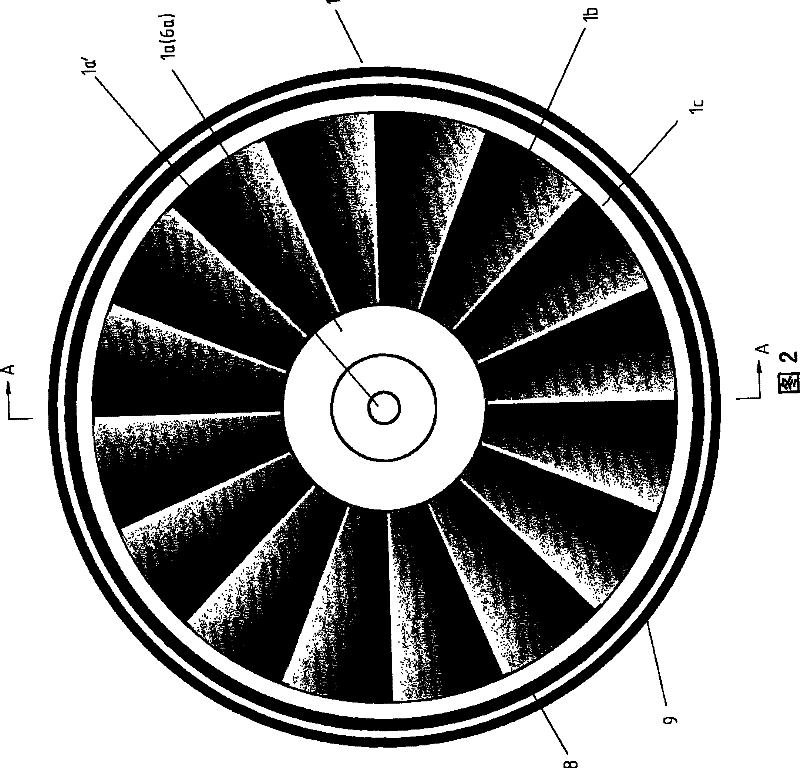

[0037] The present invention consists of seven parts: rotating fan body, outer structure ring, steering base, rotating fan body permanent magnetic levitation, crawler magnetic motor and generator, steering base permanent magnetic levitation, steering magnetic motor, and fairing, wherein:

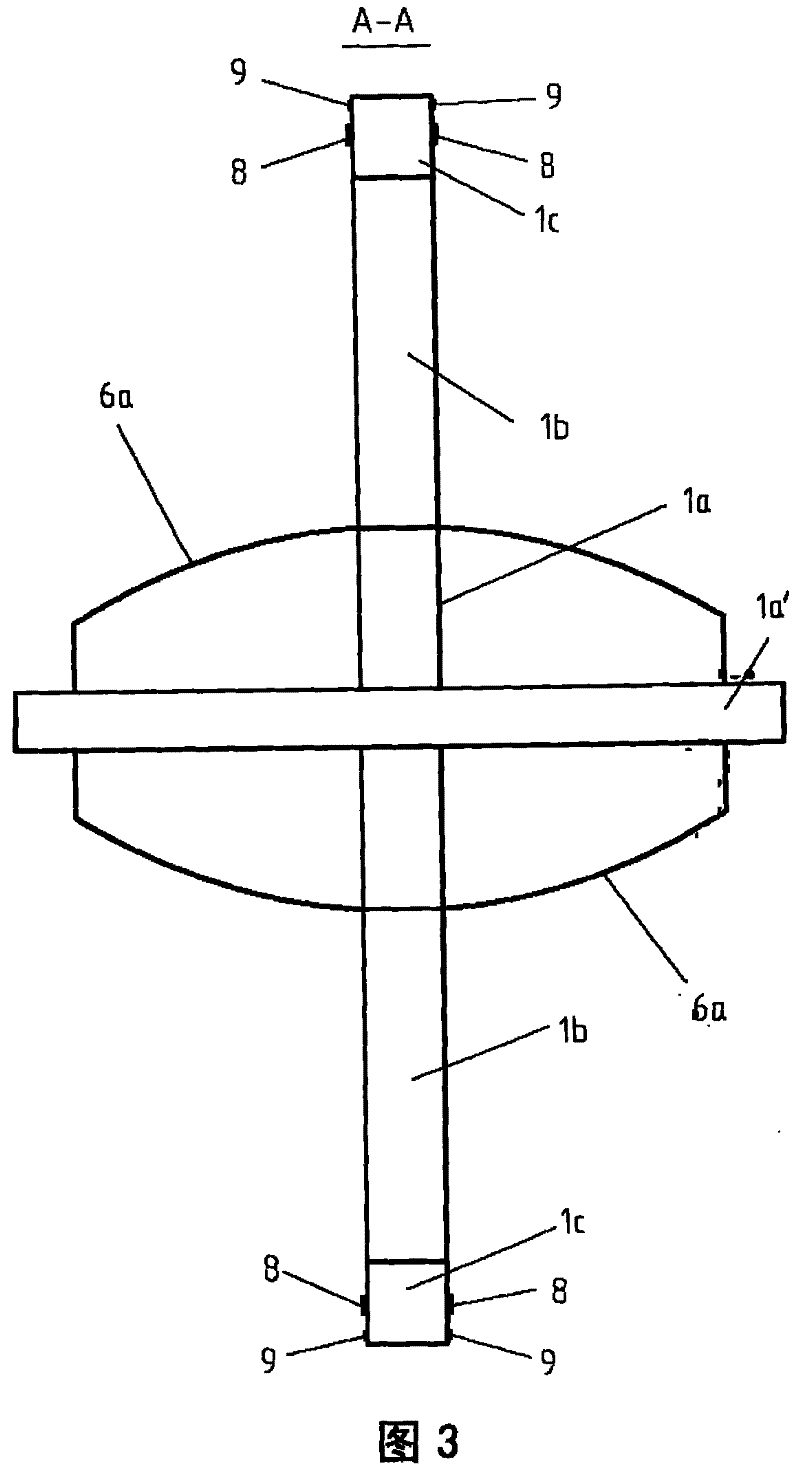

[0038] Rotary fan body part: It consists of three parts: the rotating fan hub, the rotating fan ring and the rotating fan. The fan hub is set in the center of the fan body and is made of metal such as but not limited to aluminum alloy. It is a structural part connecting the fan. The fan shaft is arranged in the center of the fan hub and is made of metal (such as but not limited to carbon steel). . The rotating fan ring is arranged on the outer ring of the rotating fan body, and is made of metal (such as but not limited to aluminum alloy), and its inner edge is connected with the rotating fan. On both sides of the rotating fan ring, there are respectively ring-shaped linear stator shoes and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com