Plastic inner lining barrel faucet prestress glass fiber reinforced plastic concrete pipe

A technology for reinforced concrete pipes and concrete pipes, which is applied in the directions of pipes, rigid pipes, and pipeline connection arrangements, can solve the problems of large friction coefficient of the inner wall of the pipe, large friction coefficient of the inner wall of the pipe, high transportation and construction costs, and achieves good The effect of sealing water of joints, improving the ability to resist uneven settlement, and saving the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

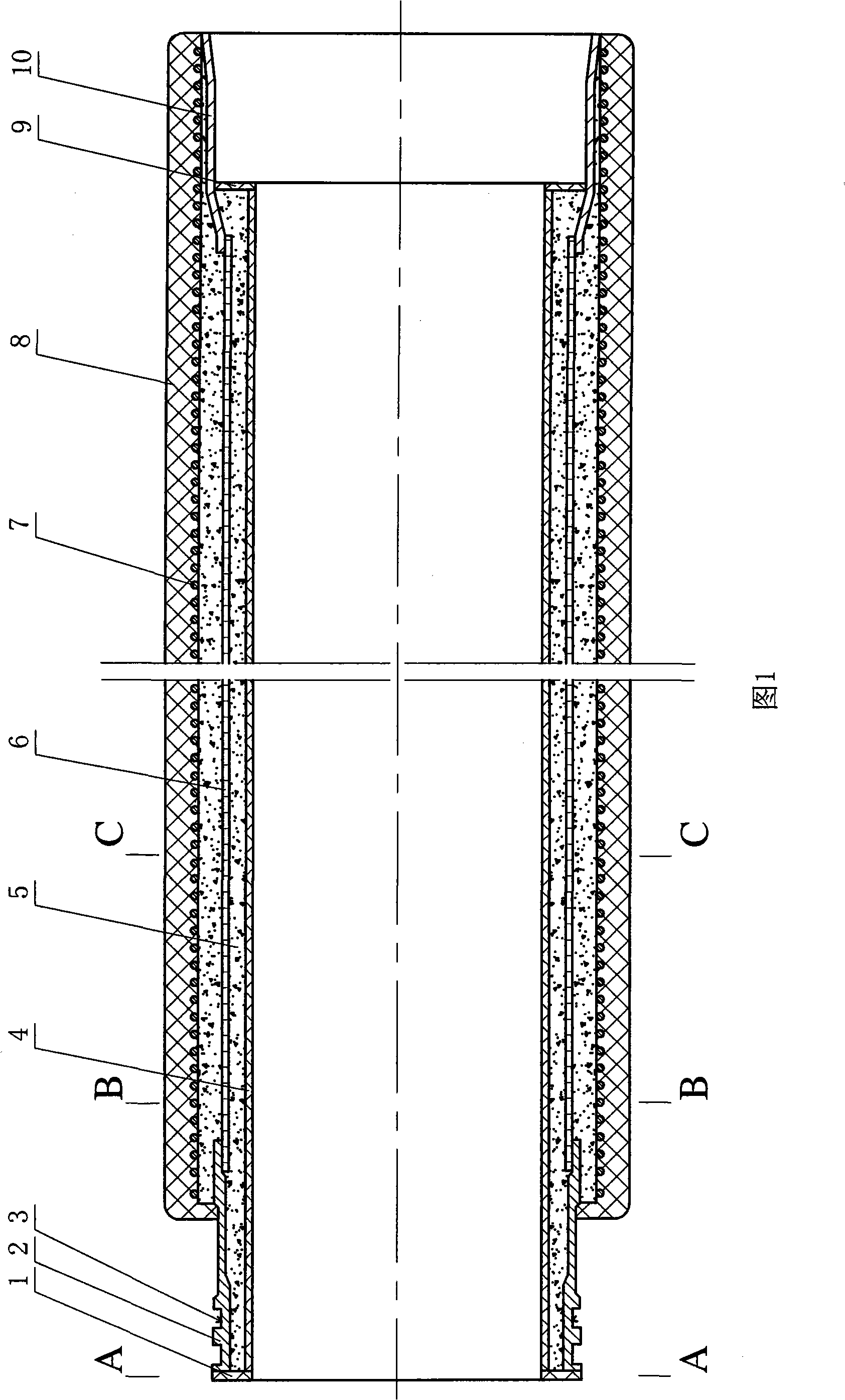

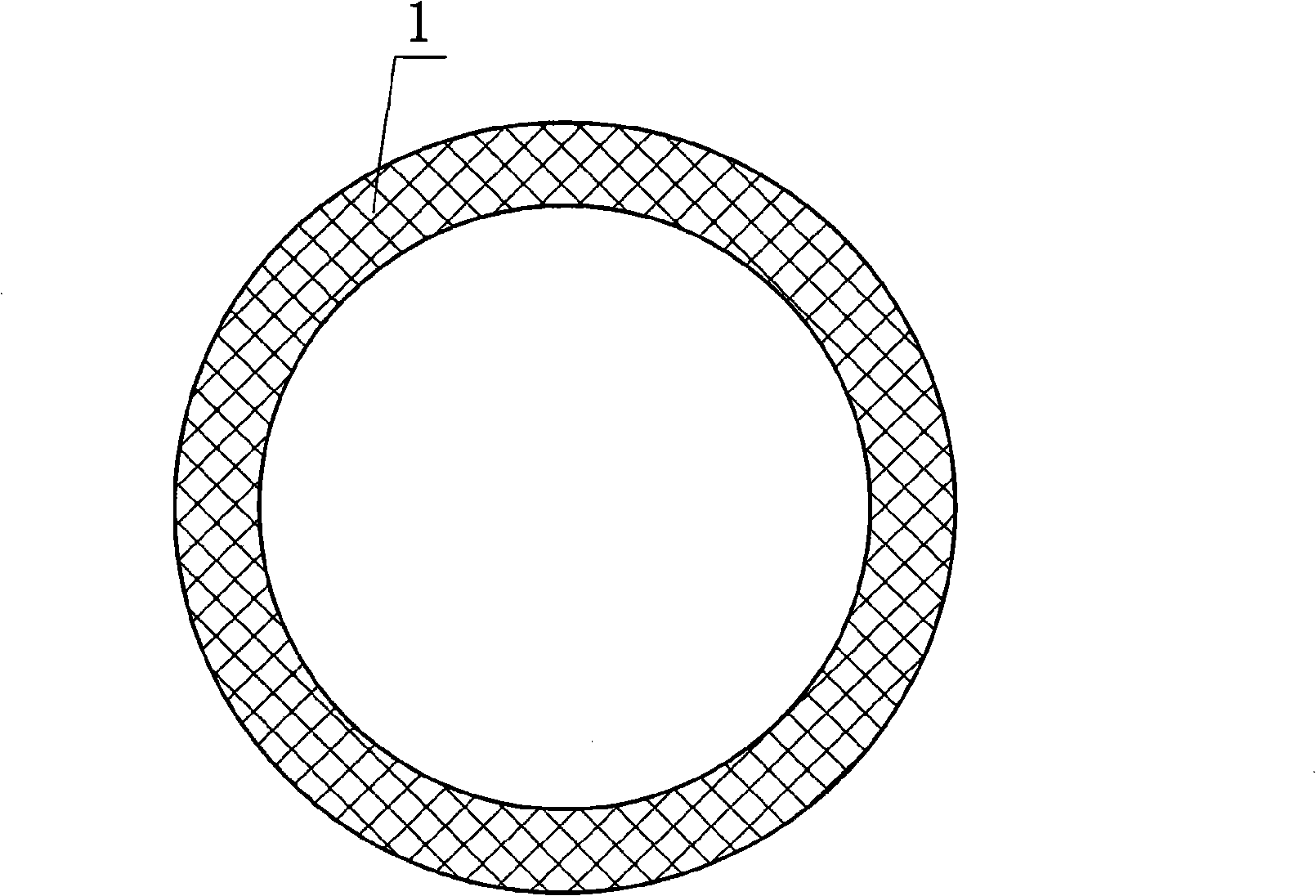

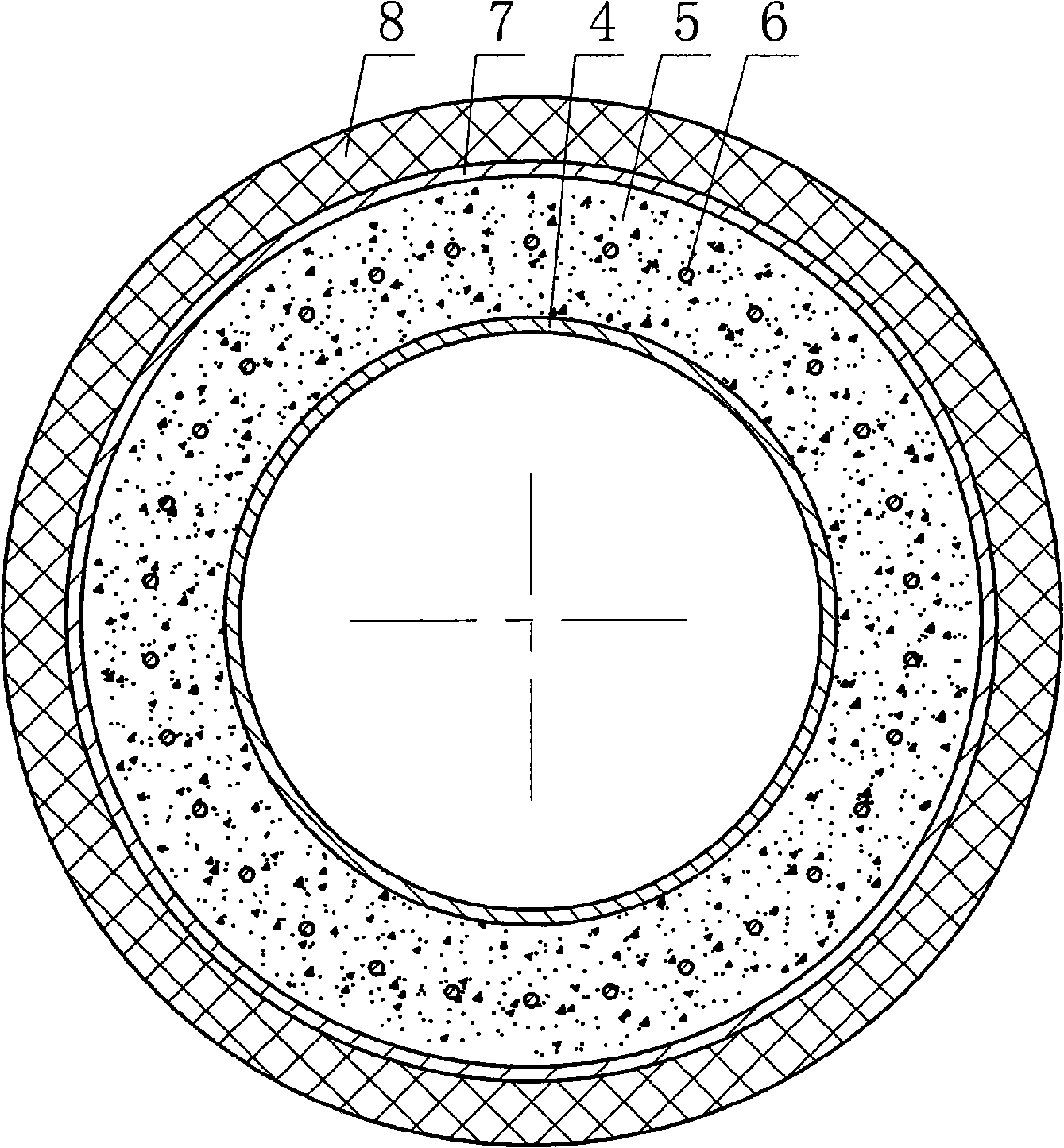

[0023] The prestressed FRP reinforced concrete pipe with plastic inner sleeve socket is composed of socket 10, socket 2, concrete pipe core 5 and prestressed steel wire 7. The socket and socket are respectively fixed at both ends of the concrete pipe core. Prestressed steel wires are wound on the outer wall of the tube core, and 30 longitudinal steel bars 6 are coaxially and uniformly embedded in the concrete tube core, and the two ends of the longitudinal steel bars are respectively fixed on the socket and the socket, and the outer wall of the socket can be radially Be shaped with 1-3 grooves 3 (shown as 2 grooves in the drawings of this embodiment), wherein the outer wall of the concrete pipe core is coaxially fixed with a glass fiber reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com