Coil tube type steam generation apparatus

A steam generating device and steam technology applied in the field of pressure vessels to achieve good energy saving effect, high steam generation rate and wide heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

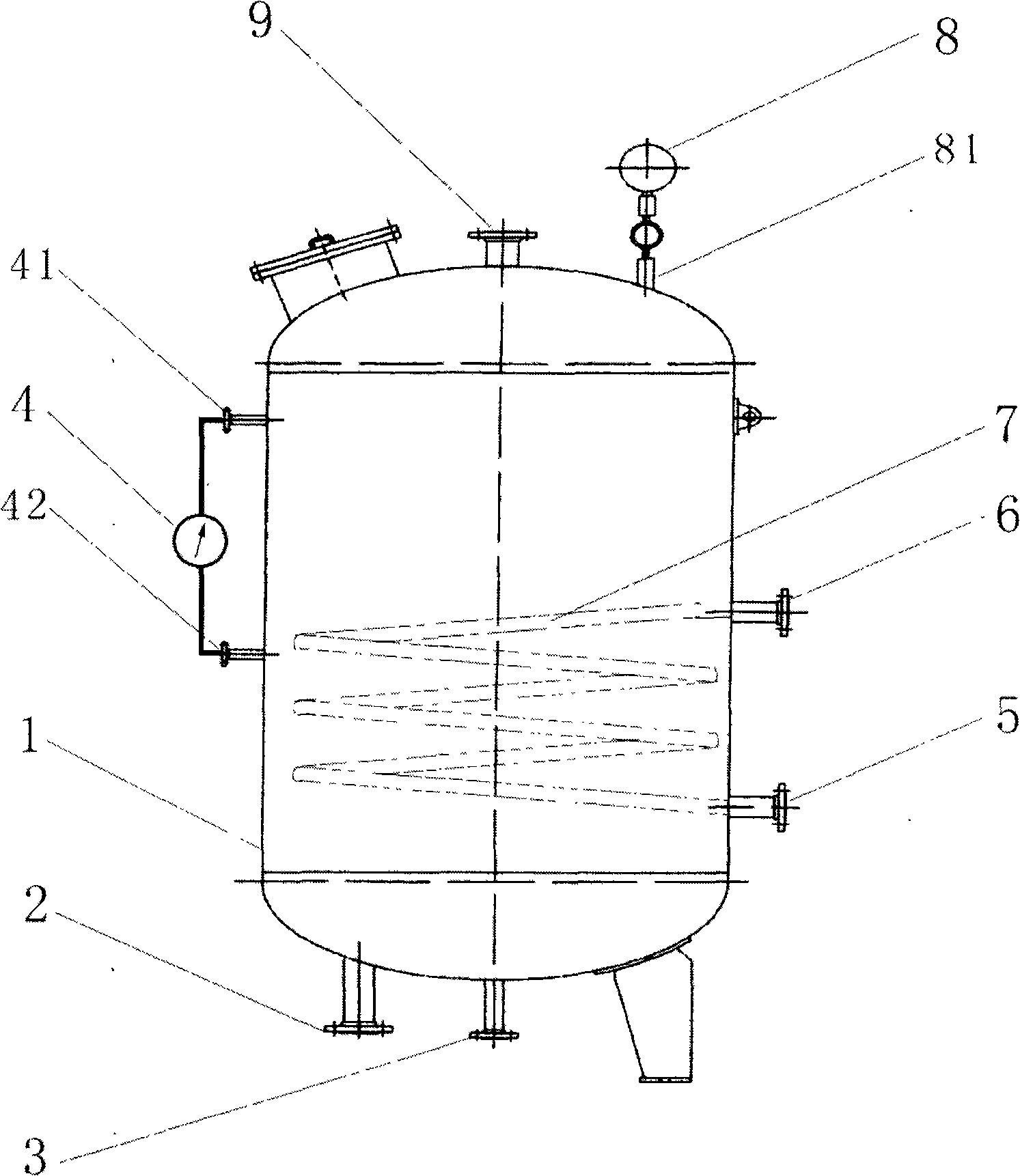

[0008] The utility model consists of a pressure vessel (1), a soft water inlet (2), a sewage outlet (3), a liquid level gauge (4), a heat transfer oil inlet (5), a heat transfer oil outlet (6), a heat transfer oil coil (7) ), pressure gauge (8), steam outlet (9) and other parts.

[0009] The utility model adopts a pressure vessel (1) constructed of carbon steel material, which can withstand a pressure of 3.0 MPa at most, and is provided with a soft water inlet (2), a sewage outlet (3) and an upper interface of a liquid level gauge on the periphery of the pressure vessel (1) (41), liquid level gauge lower interface (42), heat transfer oil inlet (5), heat transfer oil outlet (6), pressure gauge interface (81), steam output port (9); soft water inlet (2), sewage outlet (3), the heat transfer oil inlet (5), the heat transfer oil outlet (6), the steam output port (9) and the outside are all connected by flanges. A liquid level gauge (4) is installed on the upper and lower interfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com