Crane simulation operation training system

A simulation operation and training system technology, applied in the field of crane simulation operation training system, can solve the problems of trainees not being proficient in crane operation skills, skills, potential safety hazards, and high cost, so as to reduce training costs, save energy, and increase training time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

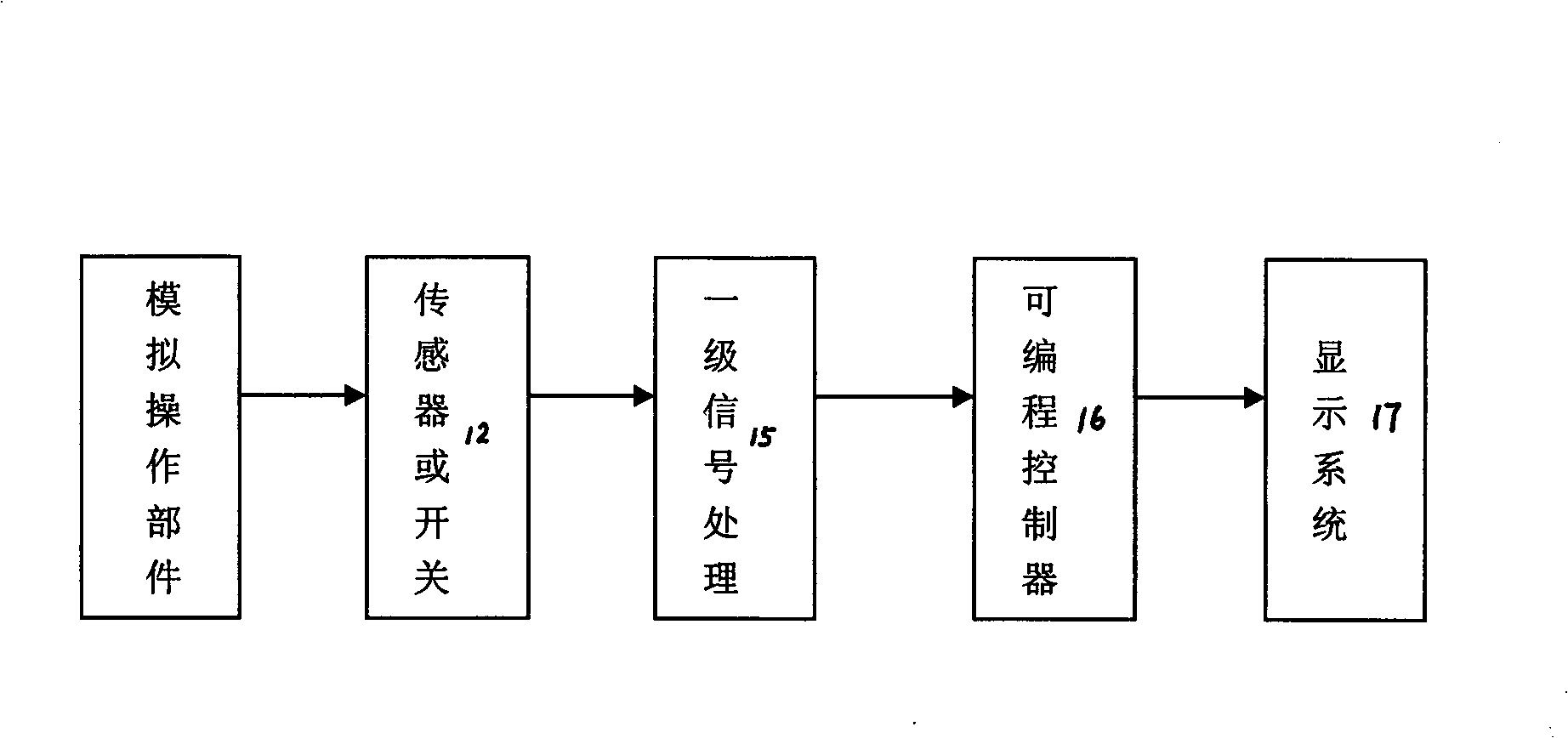

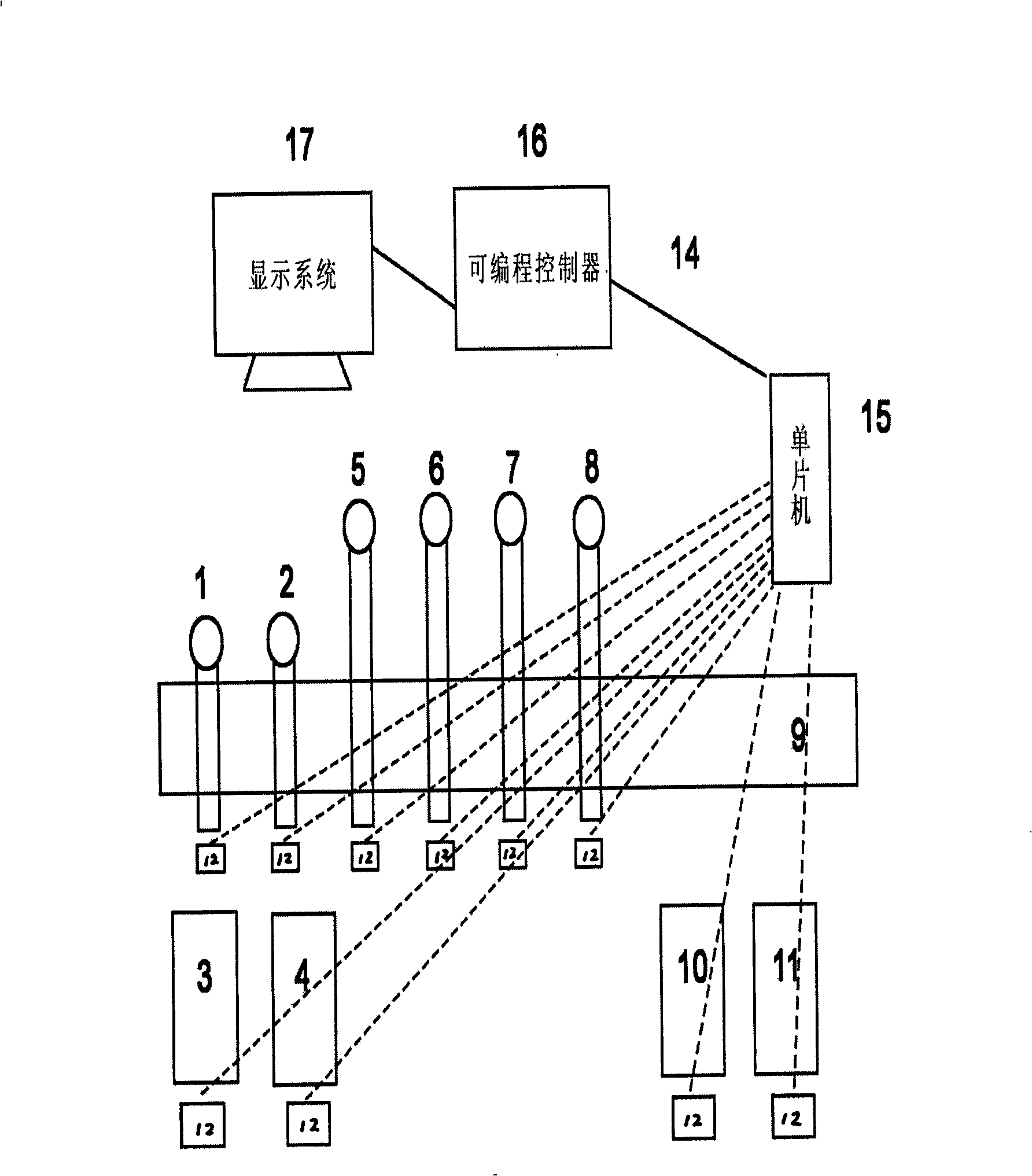

[0013] Such as figure 1 As shown, the system is composed of simulator operating components, sensing system or switch 12, primary signal processing system 15, programmable controller 16 (by main board, main board electrical processing unit, storage unit) and display system 17. The first-level signal processing system 15 adopts a single-chip microcomputer with signal amplification and A / D conversion functions. After the operation parts of the console collect signals through the sensing system or switches, they are transmitted to the single-chip microcomputer through the signal data line, and the single-chip microcomputer will be from the sensing system. After the signal is amplified and converted into a digital signal, it is input to the programmable controller through the data interface. After the data is processed, the programmable controller will synchronously display the operation action on the screen through the display system.

[0014] After turning on the main power switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com