Cable connecting connector

A technology for connectors and cables, applied in the field of connectors for cable connection, can solve the problems of time required, poor adhesion, and large pushing resistance, so as to reduce the load, shorten the heat transfer distance, and reduce the pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

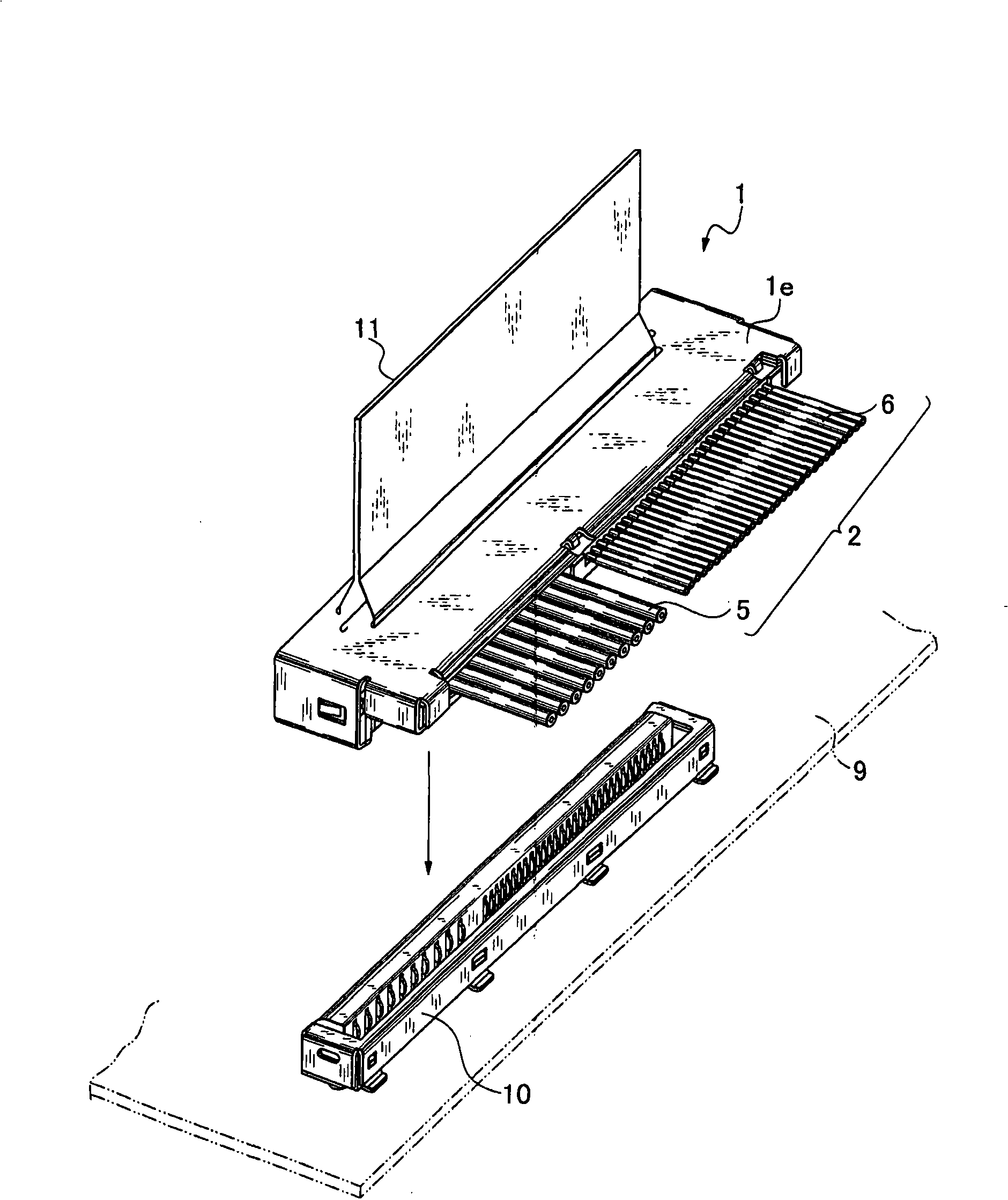

[0031] The cable connection connector 1 related to the present invention is as Figure 1 ~ Figure 3B As shown, the connector is used to connect the conductors of the cable assembly 2 ( 5a, 5b, . . . and 6a, 6a, . . . ) are collectively connected to contact 4 . Such as figure 1 As shown, the cable connection connector 1 is fitted with a connector receptacle 10 mounted on a printed circuit board 9 and is provided with a handle 11 for attachment and detachment.

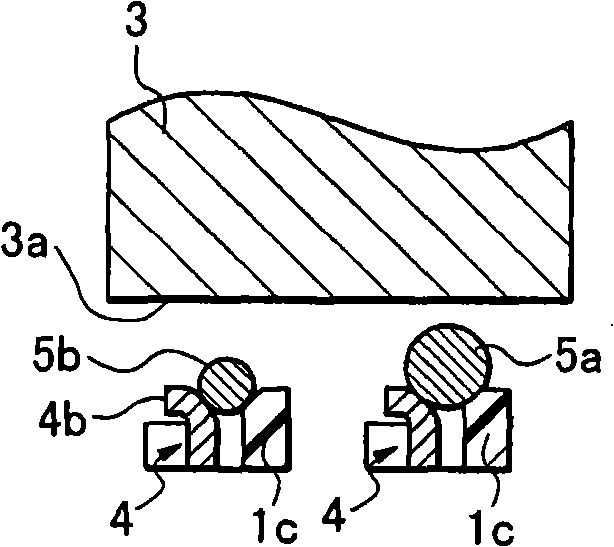

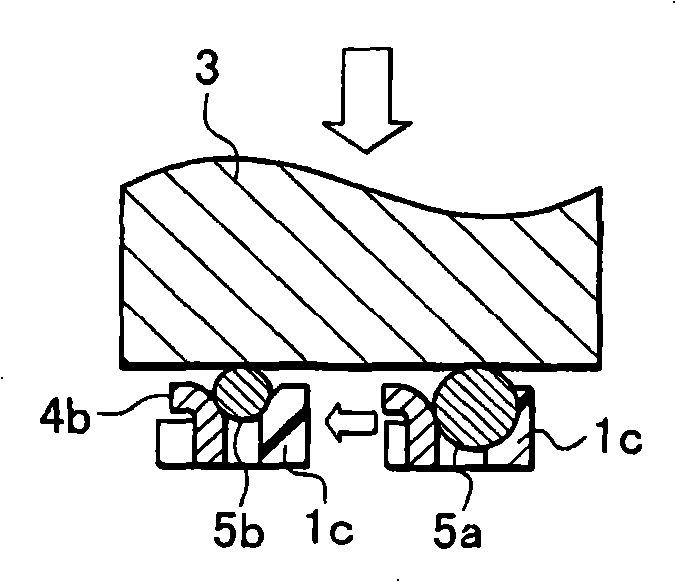

[0032] Such as figure 1 and Figure 4A As shown, the connector 1 for cable connection is composed of: a laterally elongated insulating housing 1a, and conductors 5a, 5b, 5c of discrete wires 5 arranged in a direction substantially perpendicular to the longitudinal direction of the insulating housing 1a. .. a plurality of contacts 4, 4 ... connected, contacts 7, 7 connected with conductors 6a, 6a ... of a plurality of thin-wire coaxial lines 6, and protruding between contacts 4, 4 The thermoplastic clamping base 1c i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com