Axial piston machine having a guide limb for a cage segment

An axial piston engine, branching technology, applied in reciprocating piston engines, bearings for rotary motion, shafts, etc., to achieve the effect of cheap manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

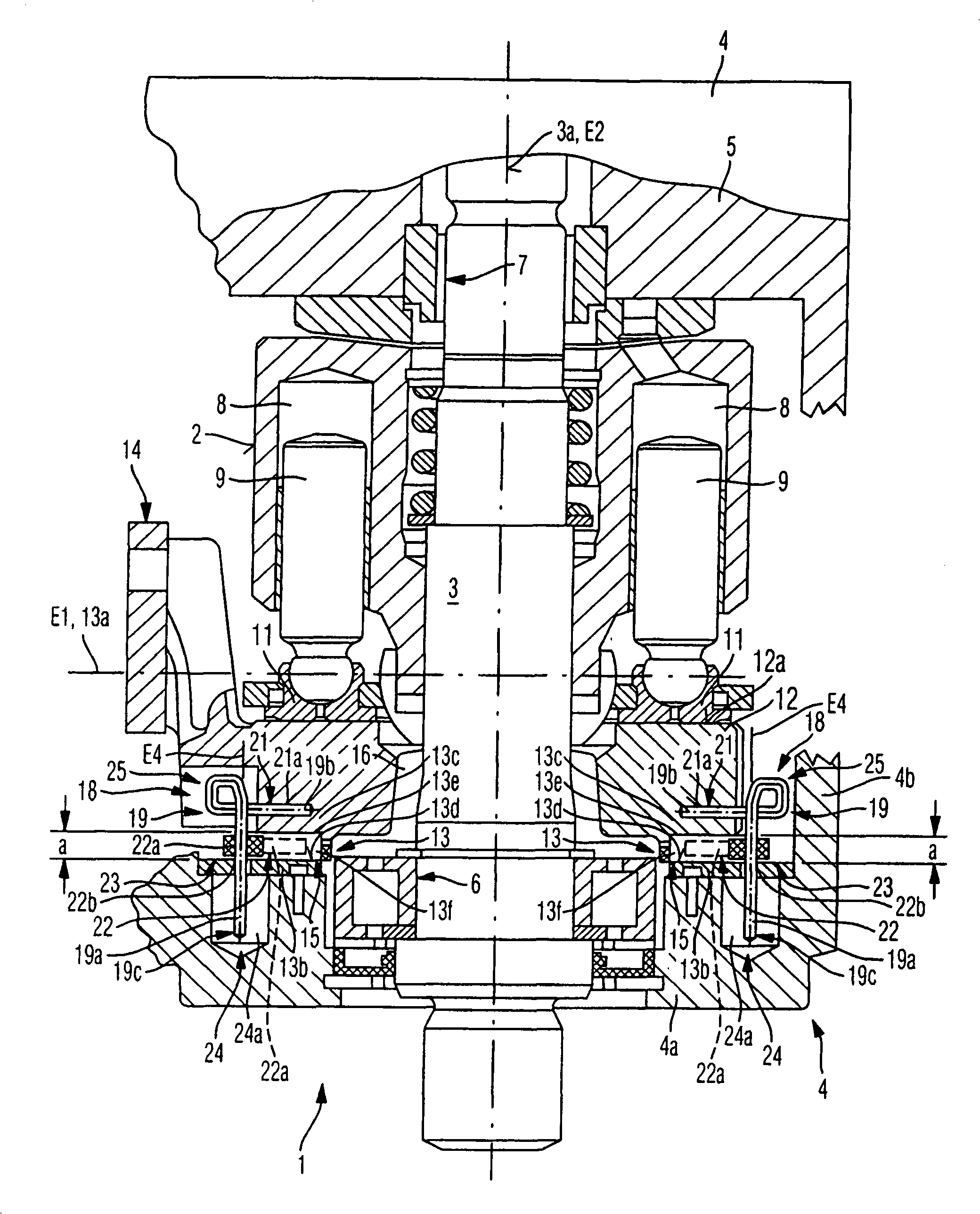

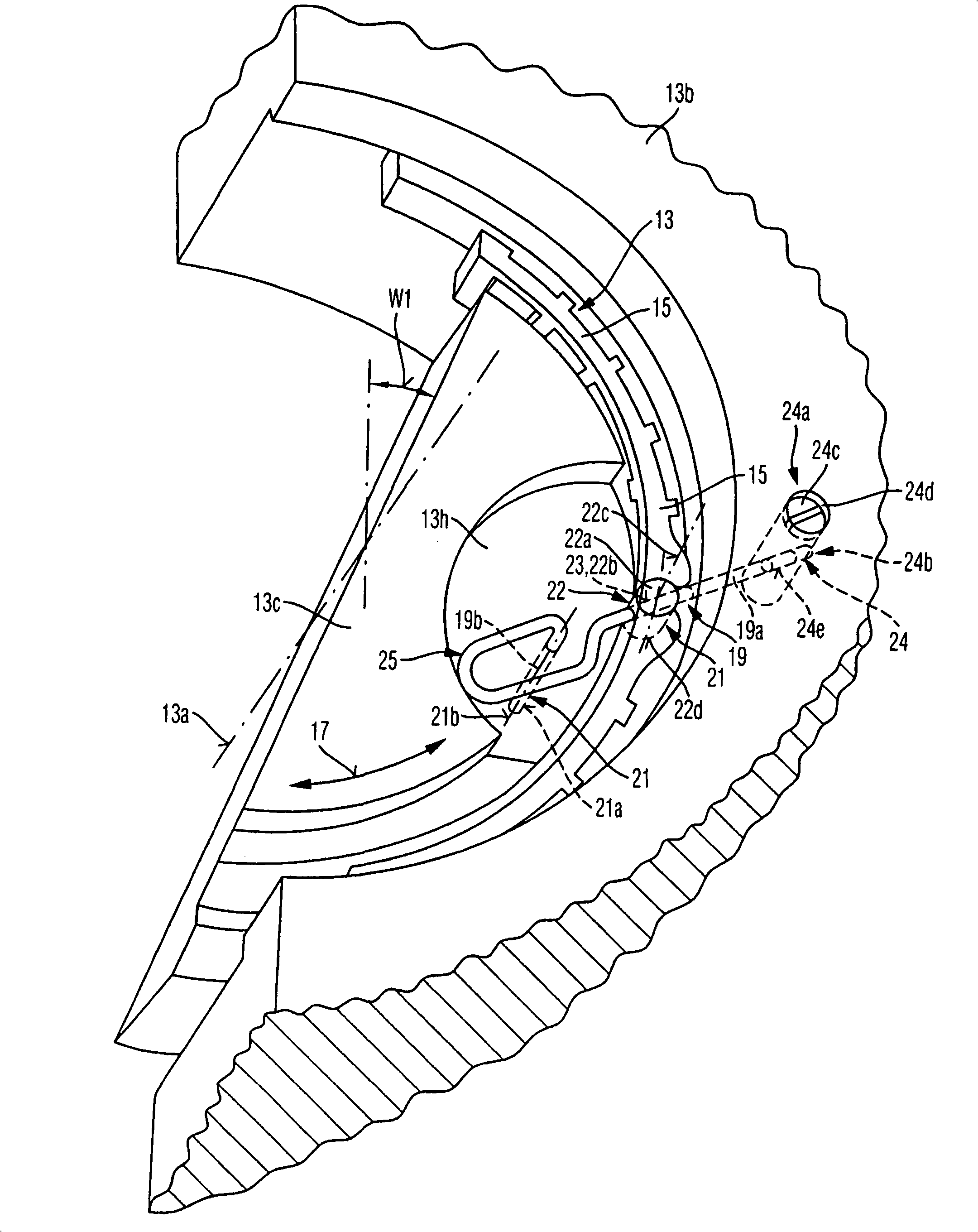

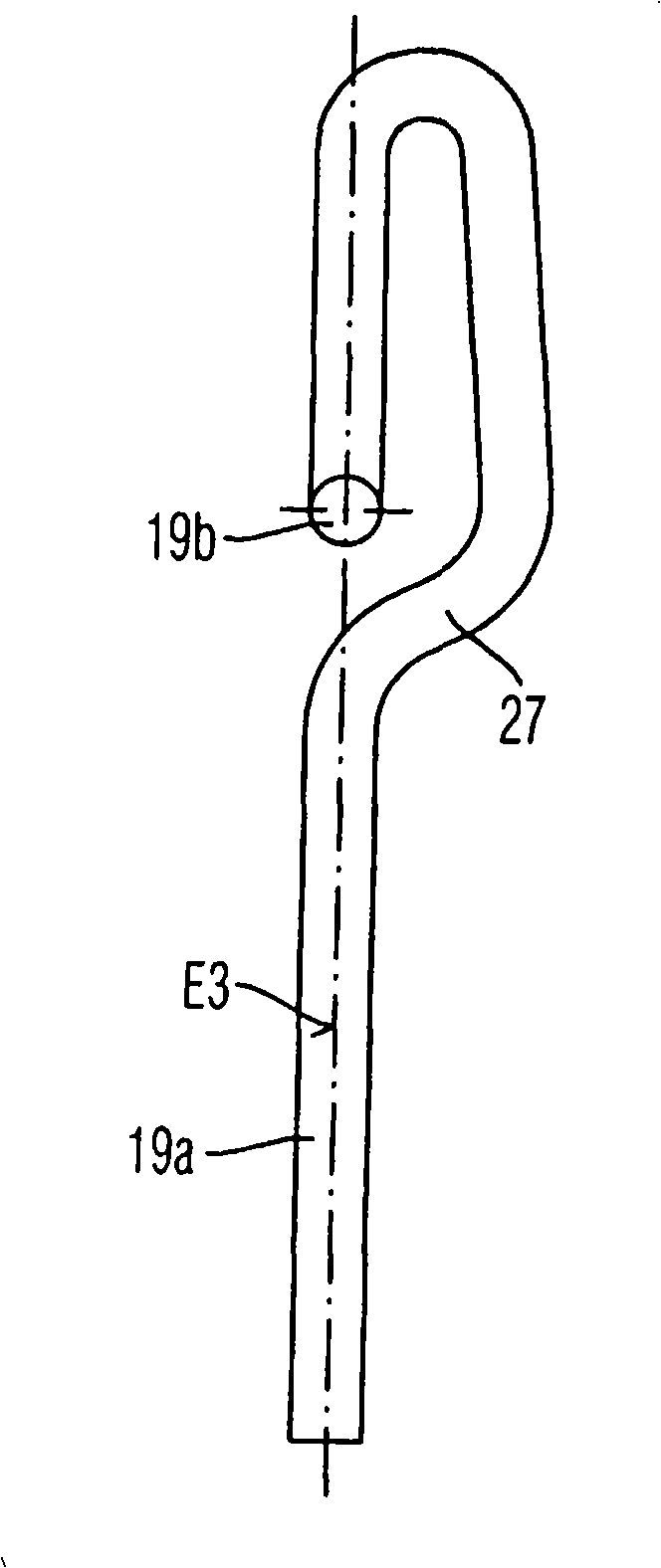

[0029] according to figure 1 , reference number 1 a complete axial piston machine having a cylinder drum 2 non-rotatably mounted on a shaft 3 through a suitable axial bore and rotatably supported by the shaft 3 on the housing shown Body 4.

[0030] The housing has, for example, a housing bottom 4a from which a partly shown peripheral wall 4b extends in the shape of a pot to a cover 5 which closes the pot-shaped housing 4 and forms a so-called connecting piece for Lines that supply and remove hydraulic circuits. The shaft 3 is rotatably supported in the rotary bearings 6, 7 on the housing bottom 4a and on the cover 5, wherein the shaft 3 forms the drive shaft 3 according to whether the axial piston machine 1 is used as a pump or as a motor, or comes out of the shaft 3.

[0031] Several cylinder bores 8 are arranged in the cylinder drum 2 distributed on the circumference, the cylinder bores 8 may extend parallel to the axis of rotation 3a of the shaft 3 or extend obliquely to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com