Novel plastic aluminum steady-state tube alclad forming device

A molding device and steady-state tube technology, applied in the direction of connecting components, mechanical equipment, etc., can solve the problems of complex structure of the molding device, poor bonding effect, complicated operation, etc., and achieve a high degree of automation, energy saving, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be further described:

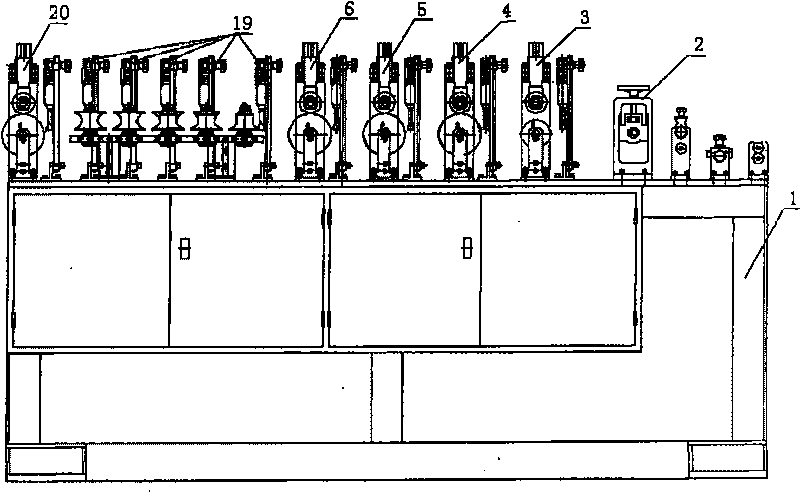

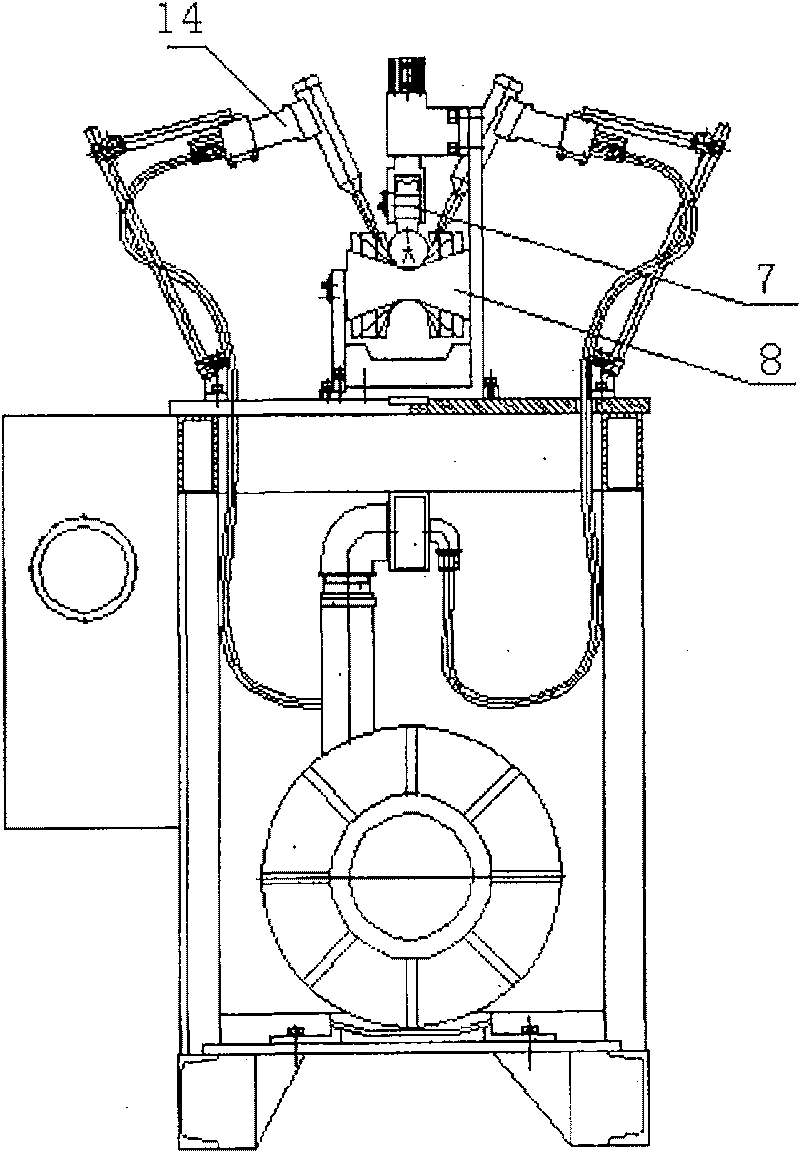

[0016] Such as figure 1 Shown, the present invention comprises a frame 1, is fixed with aluminum belt guiding device 2, three forming wheel sets and heat gun successively on frame 1, and the first forming wheel set consists of four forming devices 3, 4, 5 and 6 Arranged in sequence, such as figure 2 , image 3 As shown, each forming device is composed of a pressure wheel 7 and a forming wheel 8 corresponding vertically, and the concave arcs of the forming wheels 8 of the four forming devices are 140°, 100°, 60°, and 40° in turn. Described forming device comprises a fixed frame 9, is fixed with forming wheel 8 on the fixed frame 9, and the upper end of forming wheel 8 is fixed with cylinder 11 by support 10, and the piston rod 12 of cylinder 11 is connected with guide rod 13, and on guide rod 13 A pressure wheel 7 is fixed, and the pressure wheel 7 is vertically corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com