Postprocessing method for reducing thermal conductivity of ceramic heat barrier coating

A thermal barrier coating and thermal conductivity technology, which is applied in the post-treatment field of thermal barrier coatings, can solve problems such as thermal insulation performance and strain tolerance deterioration, so as to improve thermal insulation effect, alleviate thermal expansion mismatch, and improve thermal insulation performance. The effect of fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

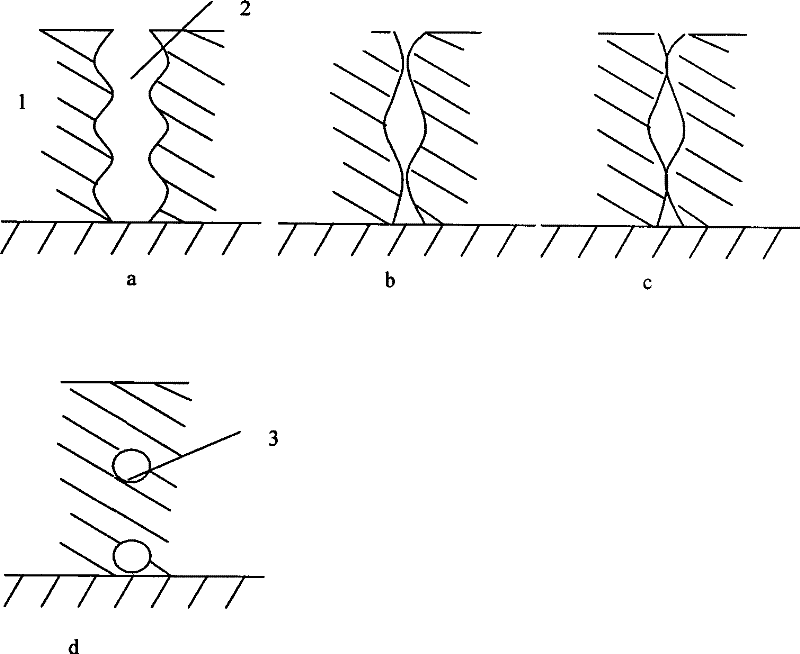

Method used

Image

Examples

Embodiment 1

[0026] The workpiece thermal barrier coating system is 6-8% yttria partially stabilized zirconia ceramic surface layer, that is, 7YSZ, thickness 0.2mm, and CoCrAlY alloy bonding bottom layer, Al content 5%, Cr 25%, Y 0.5% , the balance is Co, and the thickness is 0.1mm. Prepared by suitable spraying method (does not belong to the invention content of this patent). After surface cleaning, CO 2 The laser is used for surface heating, with a power of 150W, a spot diameter of 5mm, multi-channel overlapping scanning, an overlapping amount of 30%, a scanning speed of 10mm / s, and natural cooling. The ceramic surface layer of thermal barrier coating with limited sealing of pores and cracks is obtained.

Embodiment 2

[0028] The workpiece thermal barrier coating system is 2-3% yttria partially stabilized zirconia ceramic surface layer, namely 3YSZ, thickness 0.5mm, and NiCrAlY alloy bonding bottom layer, Al content 8%, Cr 25%, Y 0.5% , the balance is Ni, and the thickness is 0.25mm. Prepared by suitable spraying methods. After surface cleaning, use YAG laser for surface heating, power 450W, spot diameter 15mm, multi-channel overlapping scanning, overlapping amount 30%, scanning speed 20mm / s, natural cooling. The ceramic surface layer of thermal barrier coating with limited sealing of pores and cracks is obtained.

Embodiment 3

[0030] The workpiece thermal barrier coating system is 6-8% yttria partially stabilized zirconia ceramic surface layer, namely 7YSZ, thickness 0.8mm, and NiCoCrAlY alloy bonding bottom layer, Al content 12%, Cr 25%, Y 0.5% , the balance is 50% each of Ni and Co, and the thickness is 0.4mm. Prepared by suitable spraying methods. After surface cleaning, use YAG laser for surface heating, power 750W, spot diameter 25mm, multi-channel overlapping scanning, overlapping amount 30%, scanning speed 30mm / s, natural cooling. The ceramic surface layer of thermal barrier coating with limited sealing of pores and cracks is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com