Wireless remote control coreless invisible lock

A wireless remote control, invisible technology, applied in the direction of building locks, lock applications, electric registration locks, etc., can solve the problems of insecurity, damage to the lock cylinder, exposed lock cylinder and key hole, etc., to achieve powerful functions, flexible installation, The effect of high anti-theft performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

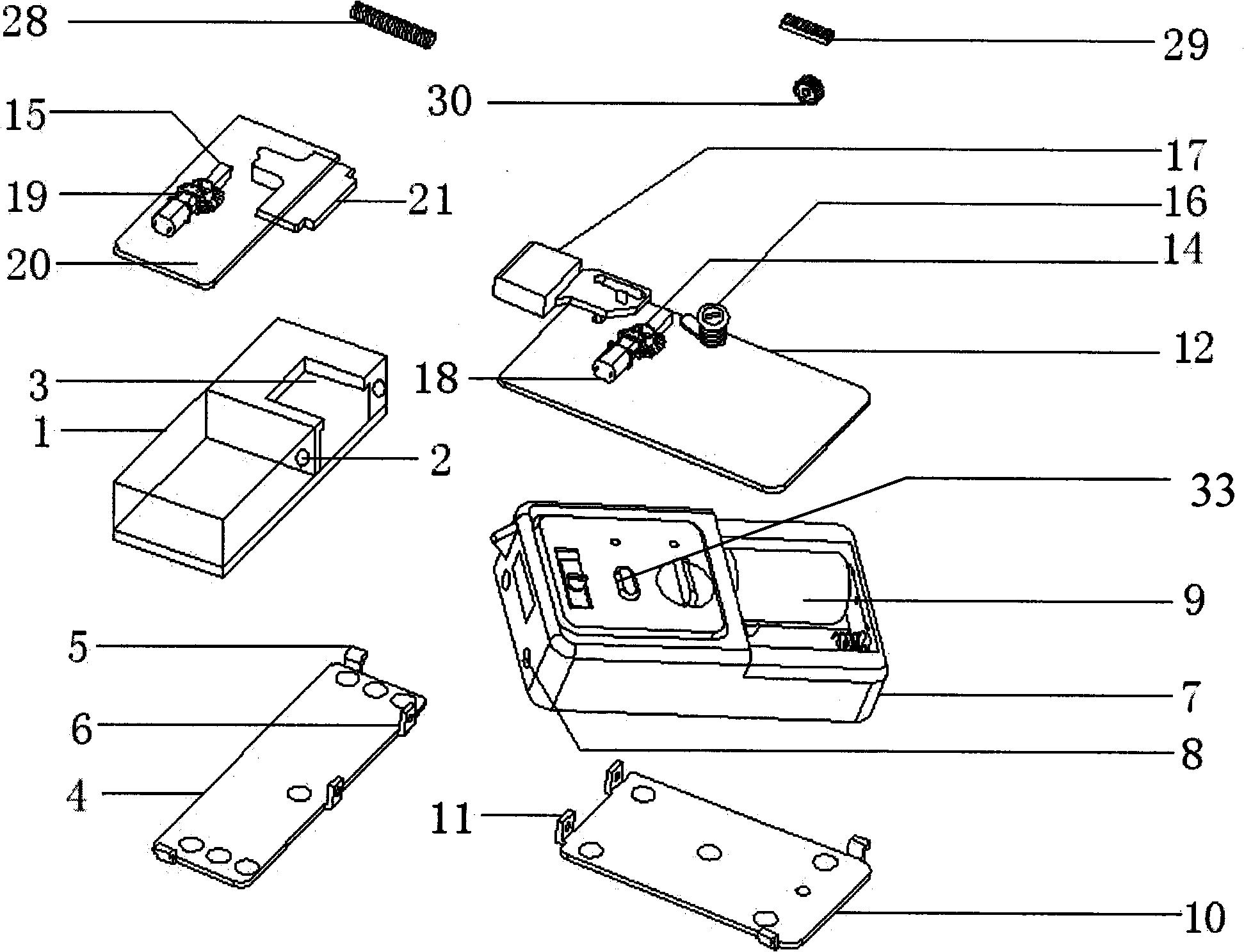

[0037] according to figure 1 As shown, when the lock body 12 is provided with one motor and the lock base 20 is provided with one motor, the unlocking process is as follows: the motor A18 of the lock body 12 works, drives the bevel gear A14 with a lever, moves the dead bolt 17, and makes the dead bolt 17 After reaching the designated position, it will automatically stop to achieve the purpose of opening / closing. If the motor A18 fails to operate, it will automatically start the action system of the lock seat 20, and the motor B19 will work. The motor B19 will drive the bevel gear B15 with the lever to move the lock seat Move the baffle 21 to make the lock seat move the baffle 21 to the position of opening / closing the seat frame, so as to achieve the purpose of opening / closing.

Embodiment approach 2

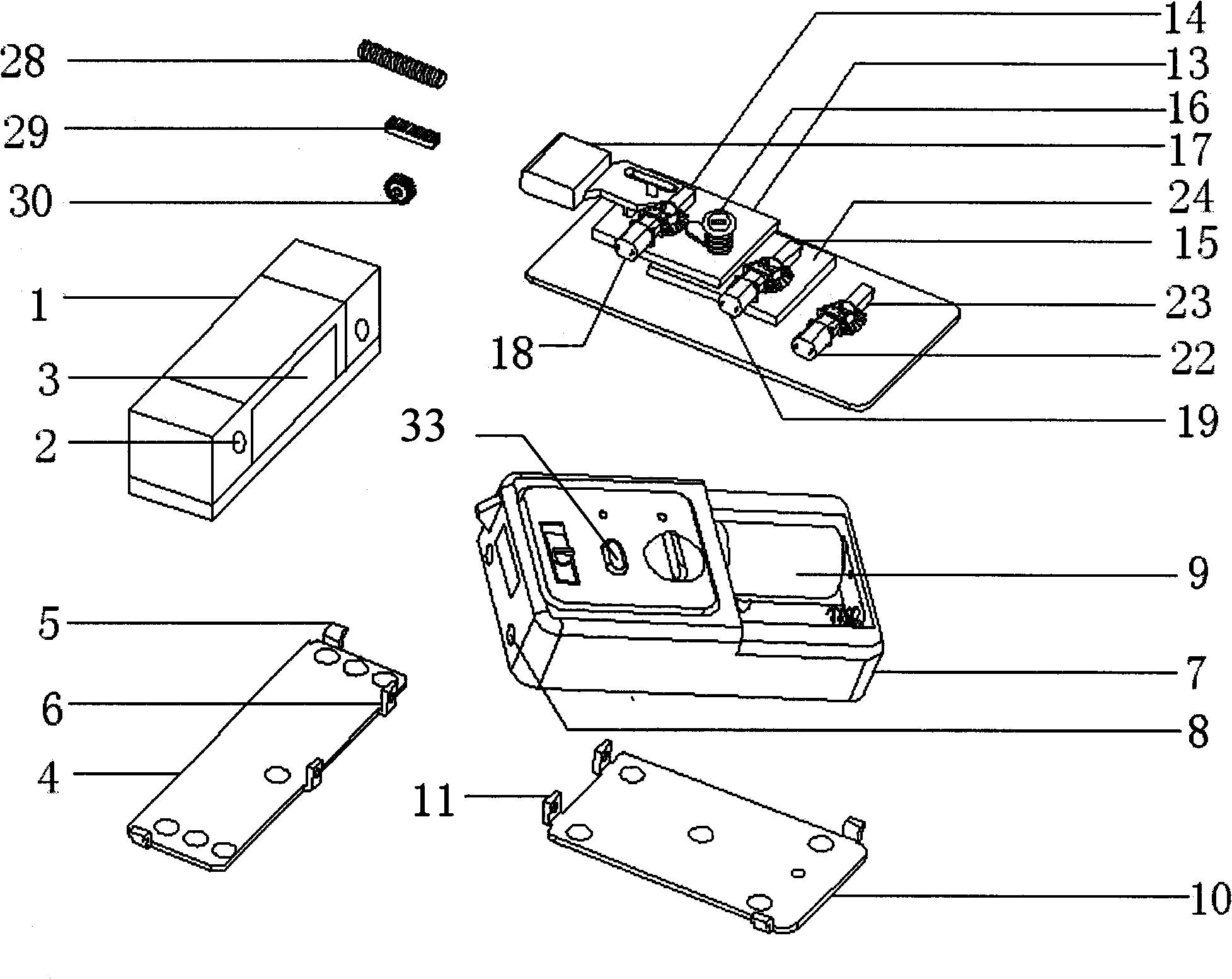

[0039] according to figure 2 As shown, when the lock body 12 is provided with 3 motors and the lock base 20 is provided with 0 motors, the unlocking process is as follows: the motor A18 of the lock body 12 works, drives the bevel gear A14 with a lever, moves the dead bolt 17, and makes the dead bolt 17 After reaching the designated position, it will automatically stop to achieve the purpose of opening / closing. When the motor A18 fails to operate, the MCU will automatically start the motor B19 to work, and the motor B19 will drive the bevel gear B15 with the lever to move the lock body. The carriage A13 drives the motor A18 to move together with the lock tongue 17, so that the lock tongue 17 reaches the designated position and completes the opening / closing action. If the motor B19 still fails, the MCU automatically starts the motor C22 to work, and the motor C22 drives the bevel gear C23 with a lever , move the lock body carriage B24, the motor A18 and the motor B19 are driven...

Embodiment approach 3

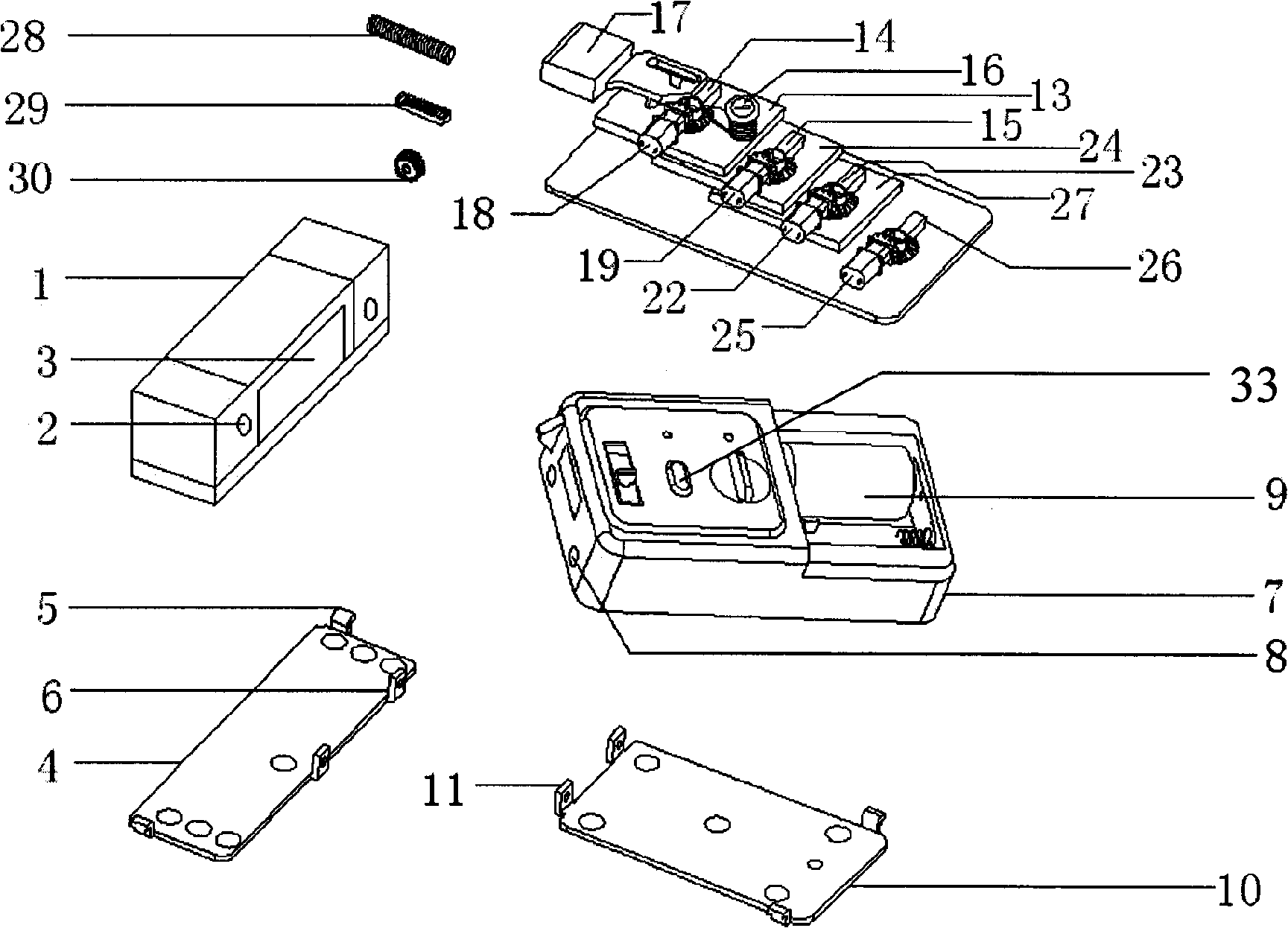

[0041] according to image 3 As shown, when the lock body 12 is provided with 4 motors and the lock base 20 is provided with 0 motors, the unlocking process is as follows: the motor A18 of the lock body 12 works, drives the bevel gear A14 with a lever, moves the dead bolt 17, and makes the dead bolt 17 After reaching the designated position, it will automatically stop to achieve the purpose of opening / closing. When the motor A18 fails to operate, the MCU will automatically start the motor B19, and the motor B19 will work, driving the bevel gear B15 with a lever, moving the lock body drag plate A13, and the lock The body drag plate A13 drives the motor A18 to move together with the lock tongue 17, so that the lock tongue 17 reaches the designated position to achieve the purpose of opening / closing. If the action of the motor B19 still fails, the MCU automatically starts the motor 22C, and the motor C22 works to drive the belt lever. Bevel gear C23, moving the lock body carriage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com