Oxygen-feeding type rotary piston machine

A rotary engine and engine technology, applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of low compression ratio, fuel consumption, etc., achieve complete combustion, clean emissions, and facilitate popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

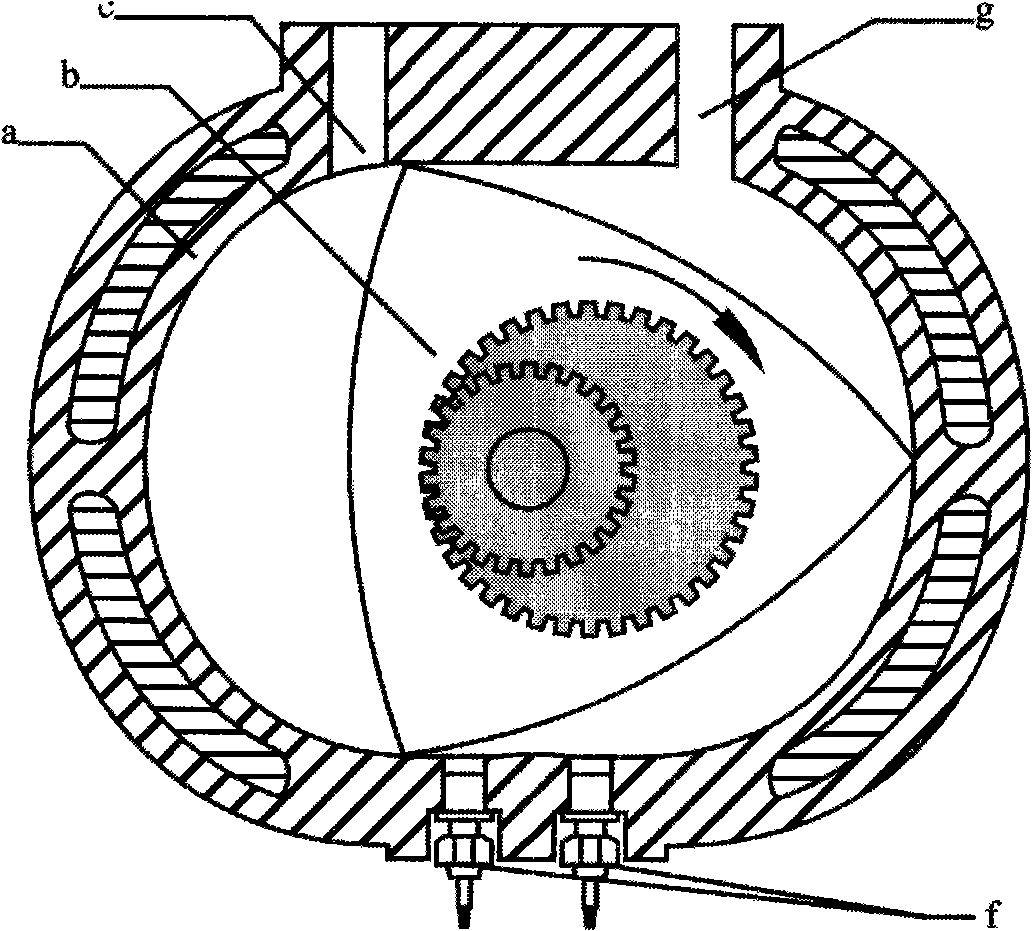

[0012] Such as figure 1 Shown is an existing rotary engine, which includes a symmetrical cocoon-shaped cylinder a, rotor b, which divides the cylinder into three chambers, and is provided with an exhaust port c and an intake port g at the end opposite to the spark plug f, and the rotor b Each working surface of the machine runs for a week through four processes of air intake, compression, work, and exhaust from the inlet g to the exhaust port c.

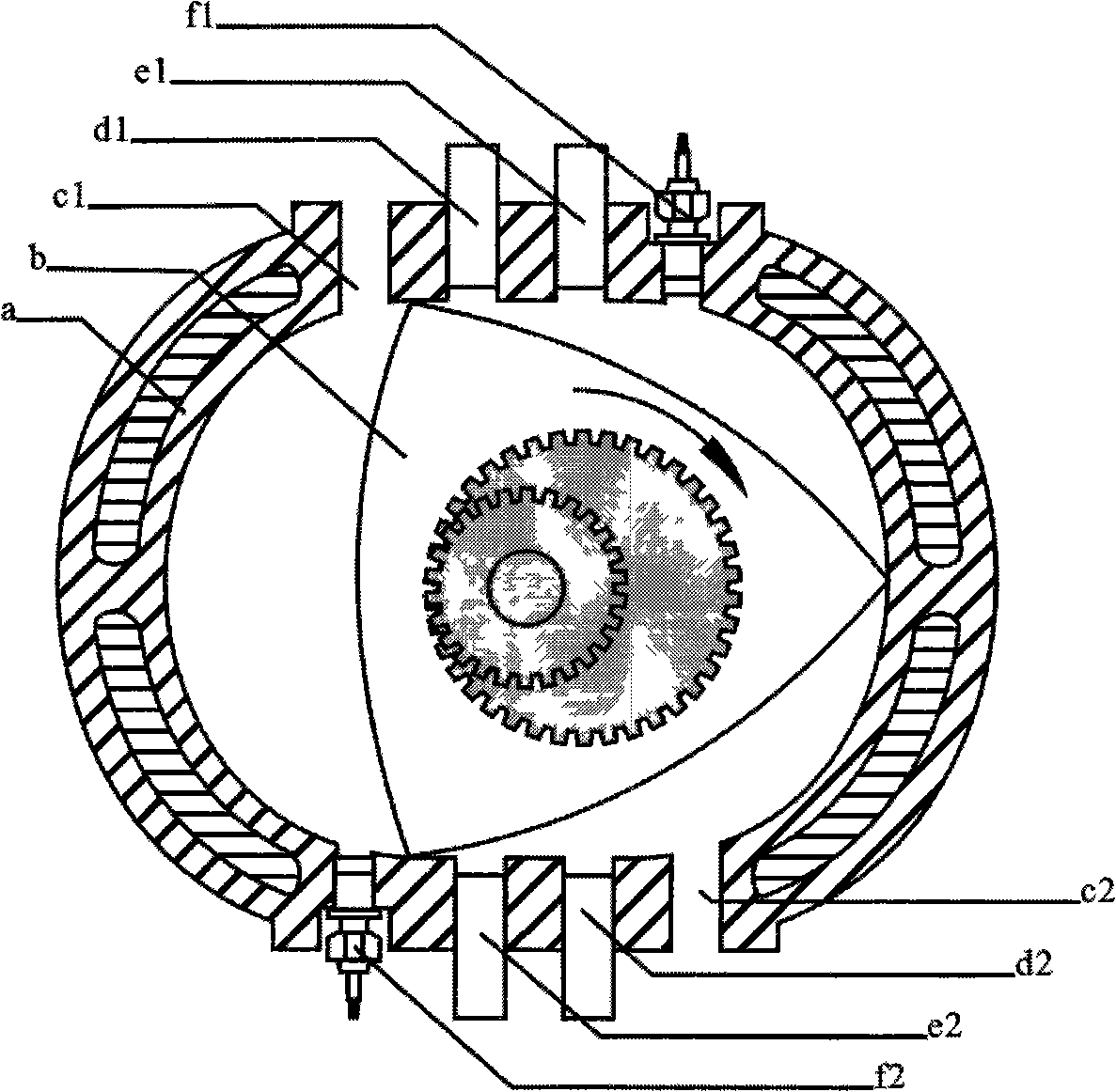

[0013] The oxygen intake type rotary engine provided by the present invention is in such as figure 1 Shown based on the existing rotary engine improved, such as figure 2 As shown, the aforementioned intake port g is canceled, and a spark plug f1, a fuel nozzle e1 and an oxygen nozzle d1 are additionally provided; a spark plug f2, a fuel nozzle e2 and an oxygen nozzle are also provided on the cylinder wall in the region where the original rotary engine works. Nozzle d2; at the position corresponding to the exhaust port c1 of the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com