Apparatus and method for cleaning of objects, in particular of thin discs

A technology for thin wafers and spray devices, applied in the field of pre-cleaning devices, can solve the problems such as the inability to obtain standardized and repeatable surface characteristics, the inability to guarantee constant quality, and the influence of processing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

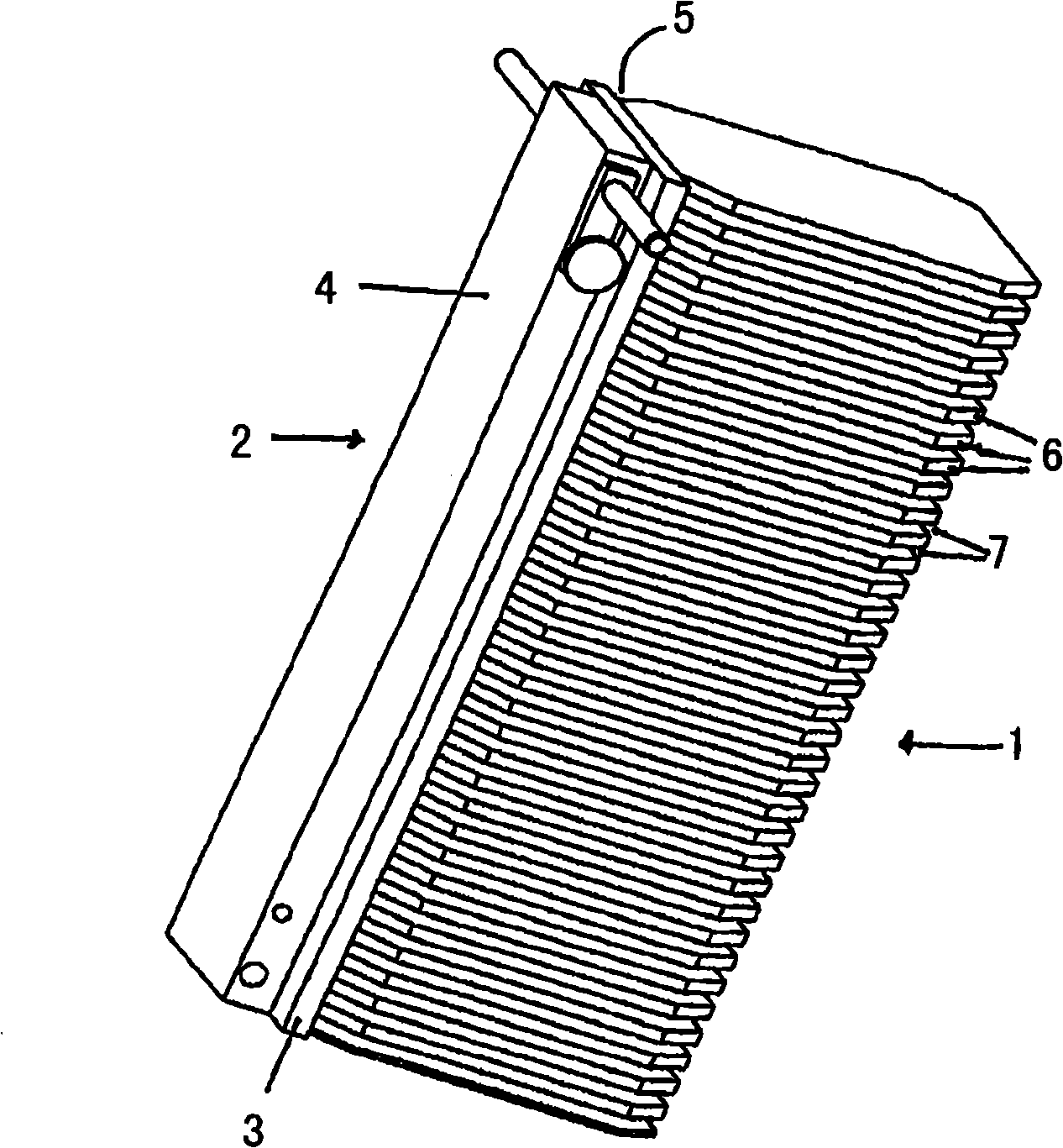

[0050] exist figure 1 Indicates the substrate billet to be cleaned. A substrate blank 1 is mounted on a carrier device 2 consisting of a glass pane 3 and a mounting element 4 . In this embodiment, one side 5 of the substrate ingot 1 is glued flat to the glass plate 3 . The sawing process that has been performed cuts into the glass pane 3 , resulting in individual substrates, also referred to as wafers 6 . Between the individual wafers 6 are formed gaps 7 in which so-called waste slurry (not shown in the figure) is present, which is to be removed according to the cleaning method of the present invention.

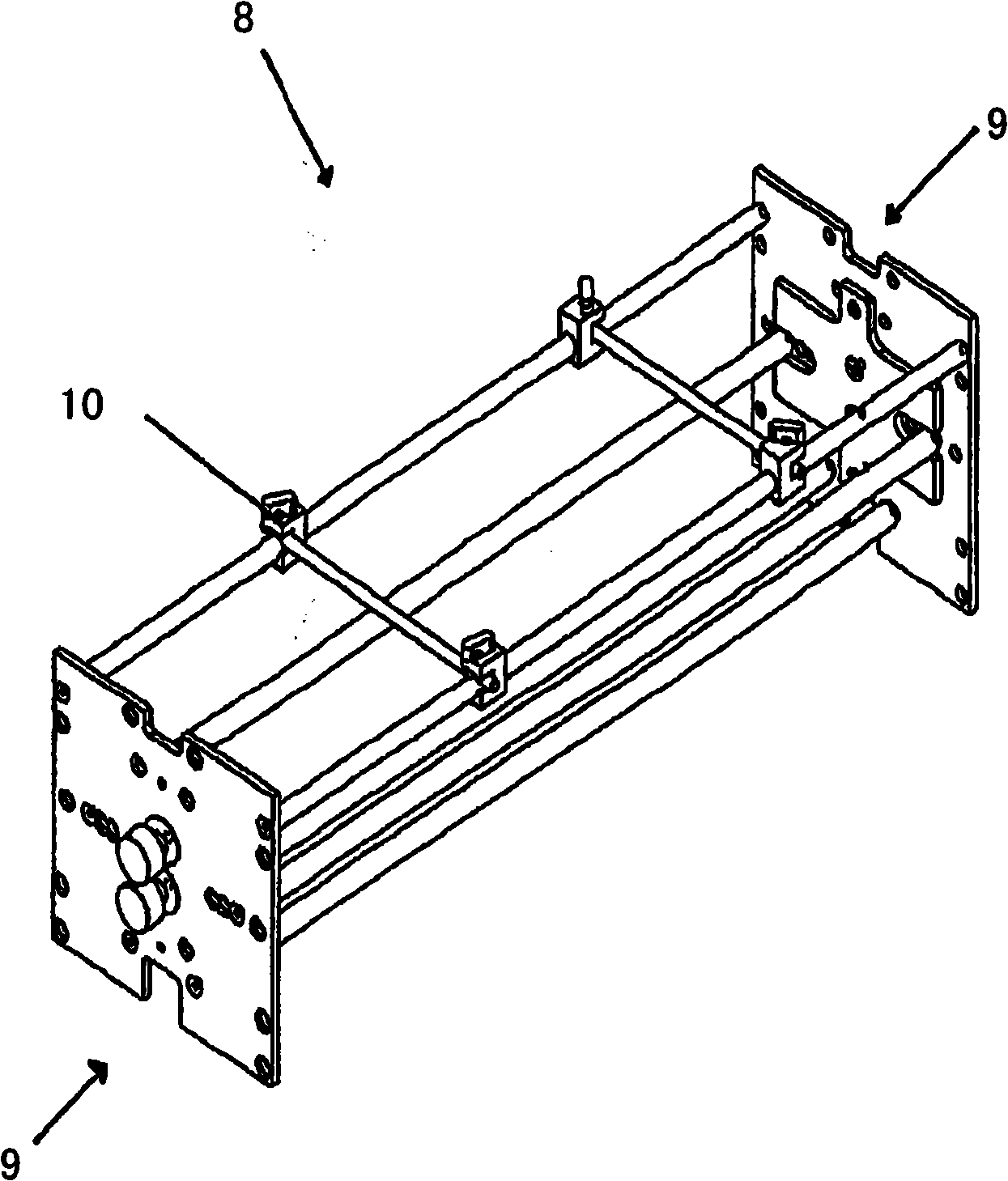

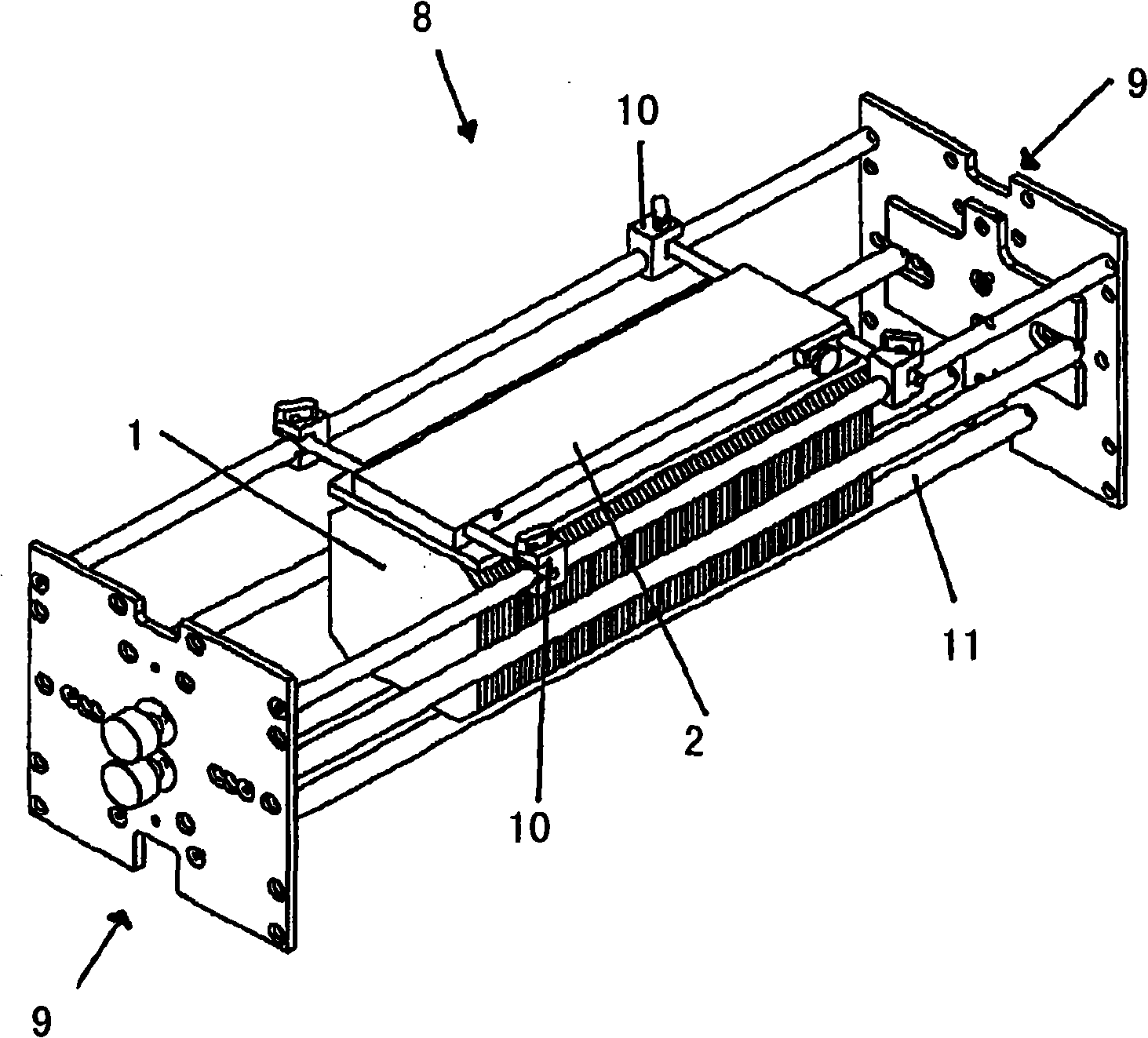

[0051] In order to transfer the substrate ingot connected to the carrier device 2 to the Figure 4 and the device described in 5, so that the carrier device 2 and the figure 2 and 3 Transport with the aids described in . Preferably, the auxiliary device 8 comprises a laterally arranged mechanism 9 which is compatible with the Figure 4 Cooperate with the device of 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com