Self-cleaning sowing device and real-time monitoring method thereof

A technology of a planter and a monitoring device, which is applied in the fields of planter parts, sowing, and optical device exploration, can solve the problems of low monitoring accuracy, difficulty in replay monitoring, etc., and achieves high monitoring accuracy, low cost, and stable monitoring performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

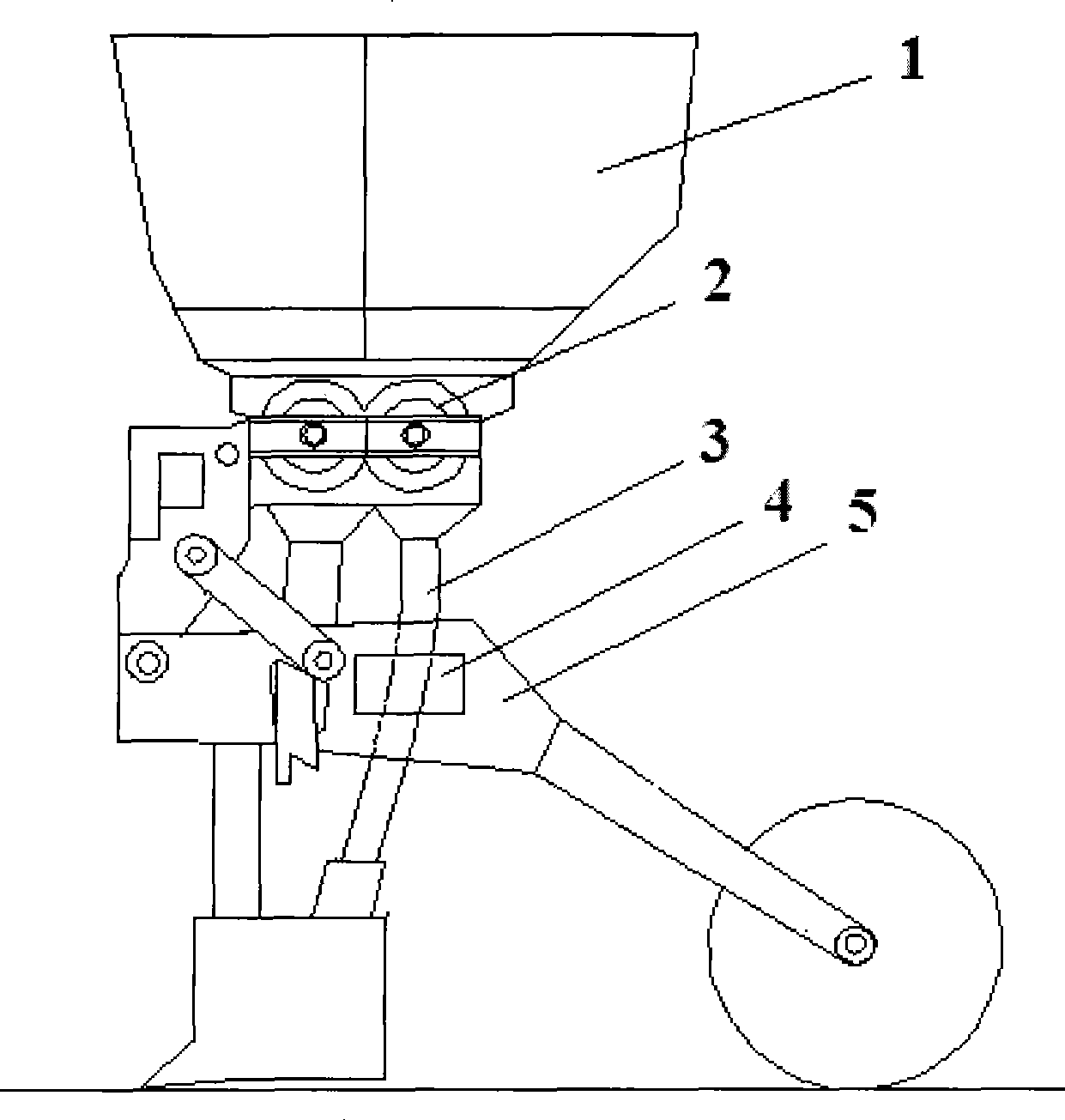

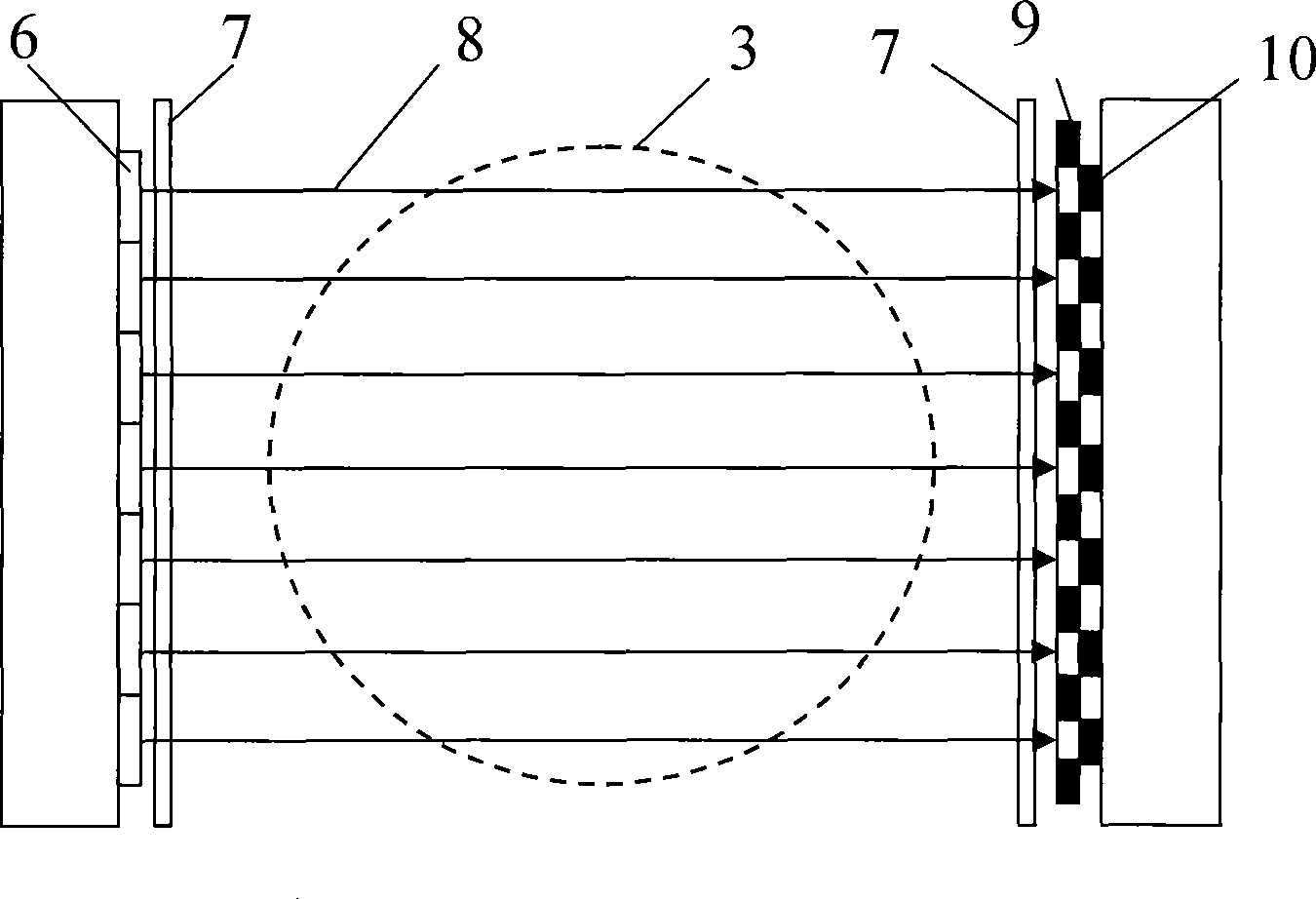

[0045] The invention provides a seeder, such as figure 1 As shown, the planter includes a seed box 1, a seed meter 2, a seed pipe 3, a monitoring device 4 and a frame 5, and the monitoring device 4 is installed on the seed pipe 3, and its main component is a sensor unit. Such as figure 2 As shown, the sensor unit includes several emitting ends 6 and several receiving ends 10 with the same number and arranged oppositely, the parallel light beams generated by the several emitting ends 6 form a grating 8, and the grating plane is perpendicular to the described seed tube 3 axis, and cover the cross-section of the entire seed tube 3, the receiving end 10 receives the parallel light beam, the transmitting end 6 in this embodiment adopts a laser transmitter, and the receiving end 10 adopts a photodiode; the monitoring device 4 It also includes a signal processing unit, which is connected to the sensor unit through an interface circuit, and judges the sowing state in the seed guide...

Embodiment 2

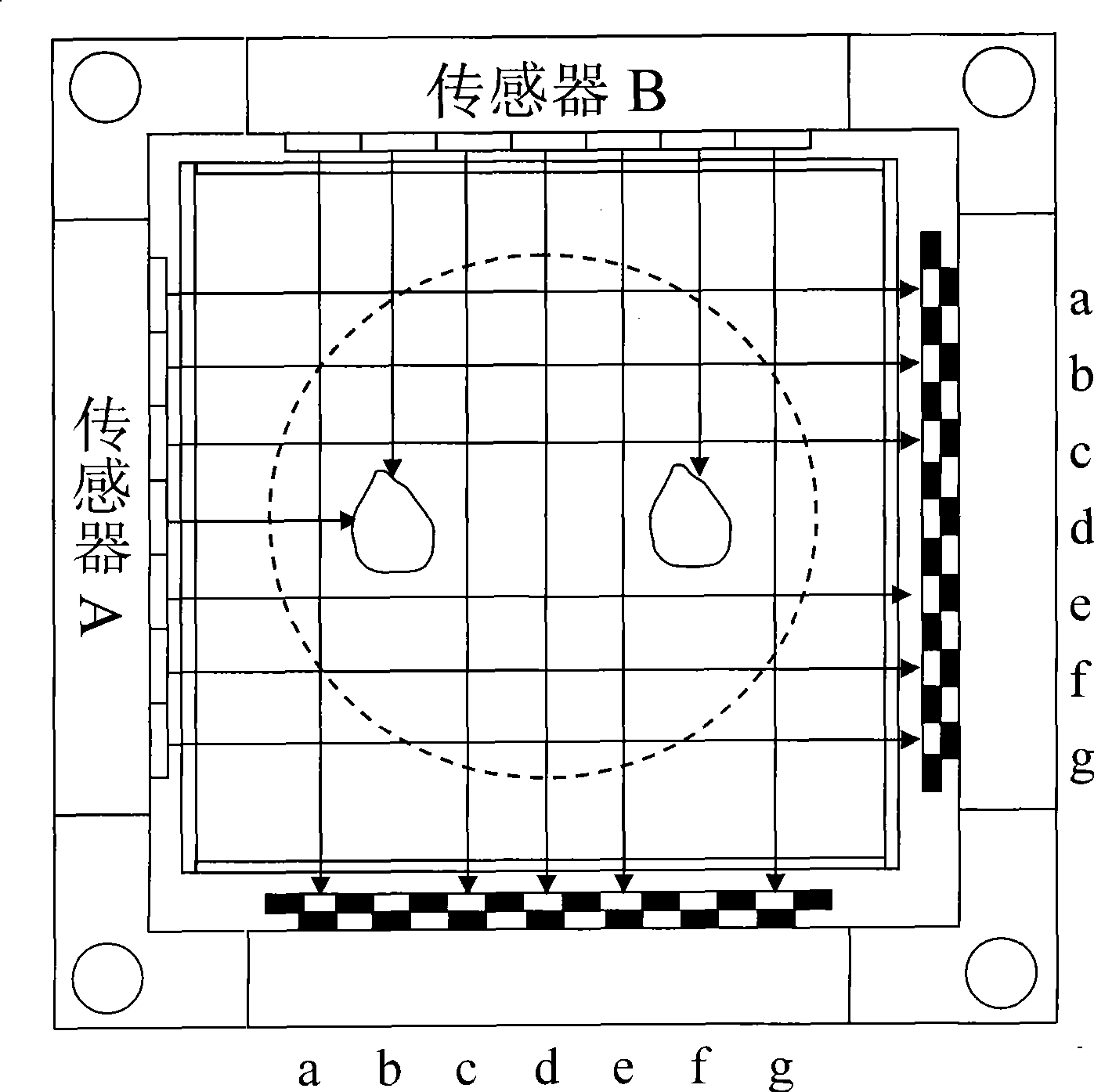

[0051] Since the size of corn seeds in each direction is quite different, and their postures are different during the sowing and falling process, it is possible to pass between the beams without blocking the beams, making the result misjudged as missed sowing. In order to solve this problem, it can be realized theoretically by reducing the beam axis spacing of the grating, but the implementation is relatively complicated. On the other hand, if two or more seeds pass through the detection area at the same time (that is, when the time difference between passing through the detection area is less than the resolution of the sensor), some seeds may be missed, that is, this type of replay cannot be accurately detected. For example, if image 3 As shown, if two seeds pass through the detection area at the same time as shown in the figure, if only one sensor A is used at this time, since the two seeds block the same light beam, only the dth output terminal on sensor A ( Denoted as Ad...

Embodiment 3

[0056] This embodiment provides a seeder with a self-cleaning function, and the seeder includes all the parts involved in Embodiment 2, such as Figure 4 with Figure 5 Shown self-cleaning device, described self-cleaning device comprises: movable bracket 11, in the shape of a square plate, with a circular hole matching the outer diameter of the described seed tube in the middle; eccentric wheel 16, installed on the movable Above the support 11, when the eccentric wheel 16 rotates, its outer edge pushes the movable support 11 to move up and down. Back and forth once; return spring 13 is located between the lower surface of the movable support 11 and the upper surface of the sensor unit group 14, under the joint action of the return spring 13 and the eccentric wheel 16, the movable support 11 moves along the guide column 12 Reciprocate up and down; some felts 15 are vertically fixed on the lower surface of the movable support 11, encircling a square that is suitable for the inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com