Polychloroethylene (PVC) high elasticity gloves and manufacturing method thereof

A polyvinyl chloride, high-elasticity technology, used in gloves, clothing, clothing, etc., can solve the problem of high price of latex gloves, and achieve the effects of improving hand feel, improving glove performance, and increasing elongation and tensile strength.

Inactive Publication Date: 2009-02-11

BLUE SAIL MEDICAL

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The current production of PVC gloves has an elongation of ≥350% and a tensile strength of ≥11Mpa. During use, due to the influence of personal hand shape, it may not be able to cling to the arm, so it is affected by some special work. However, the price of latex gloves is too high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0036] Embodiment 1: polyvinyl chloride 4000kg, plasticizer 3200kg, stabilizer 60, elastomer 160kg.

Embodiment 2

[0037] Embodiment 2: polyvinyl chloride 4000kg, plasticizer 3400kg, stabilizer 72, elastomer 200kg.

Embodiment 3

[0038] Embodiment 3: polyvinyl chloride 4000kg, plasticizer 3000kg, stabilizer 48, elastomer 240kg.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a polyvinyl chloride (PVC) high-elastic glove and a manufacturing method thereof. The invention is characterized in that an elastomer in a liquid form is added into the PVC paste; and the formula thereof used is as follows: 100 parts of PVC, 70-100 parts of plasticizer, 1.0-3.0 parts of stabilizing agent, and 5 percent to 20 percent of the elastomer (calculated by taking the parts by weight of the PVC as the base). After the PVC paste is placed in a second time stirring tank, the elastomer is added into the emulsion according to 5 percent to 20 percent of the PVC powder parts; simultaneously, according to the type gram weight of the produced glove, quantitative viscosity reducer is added, then transported to a second time material storage tank for more than 4 hours of vacuum quiescence after 2 to 4 hours of stirring, and later placed in a production line material groove for use. By taking 20 high-elastic gloves to test the physical property index, the maximum tensile strength is 15MPa and the maximum elongation rate reaches 520 percent, therefore, the elastic performance of the glove is improved significantly.

Description

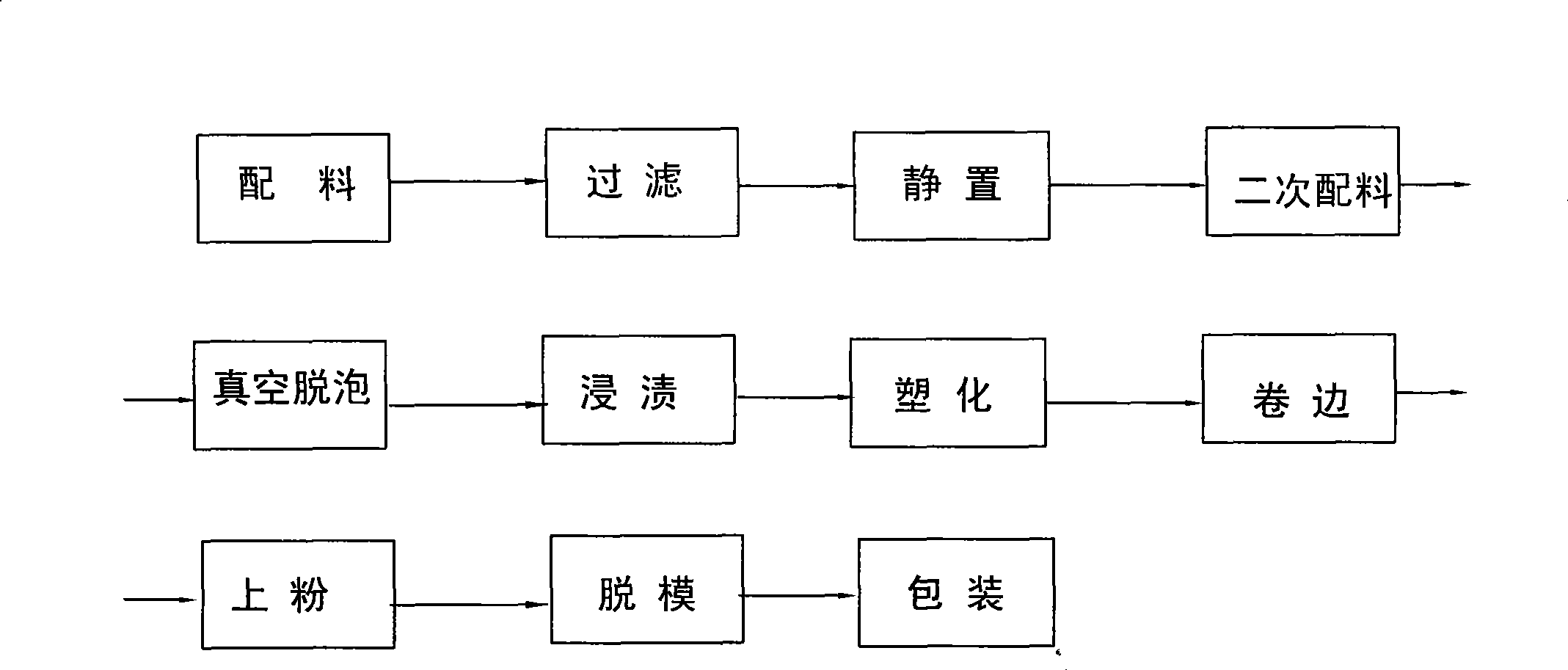

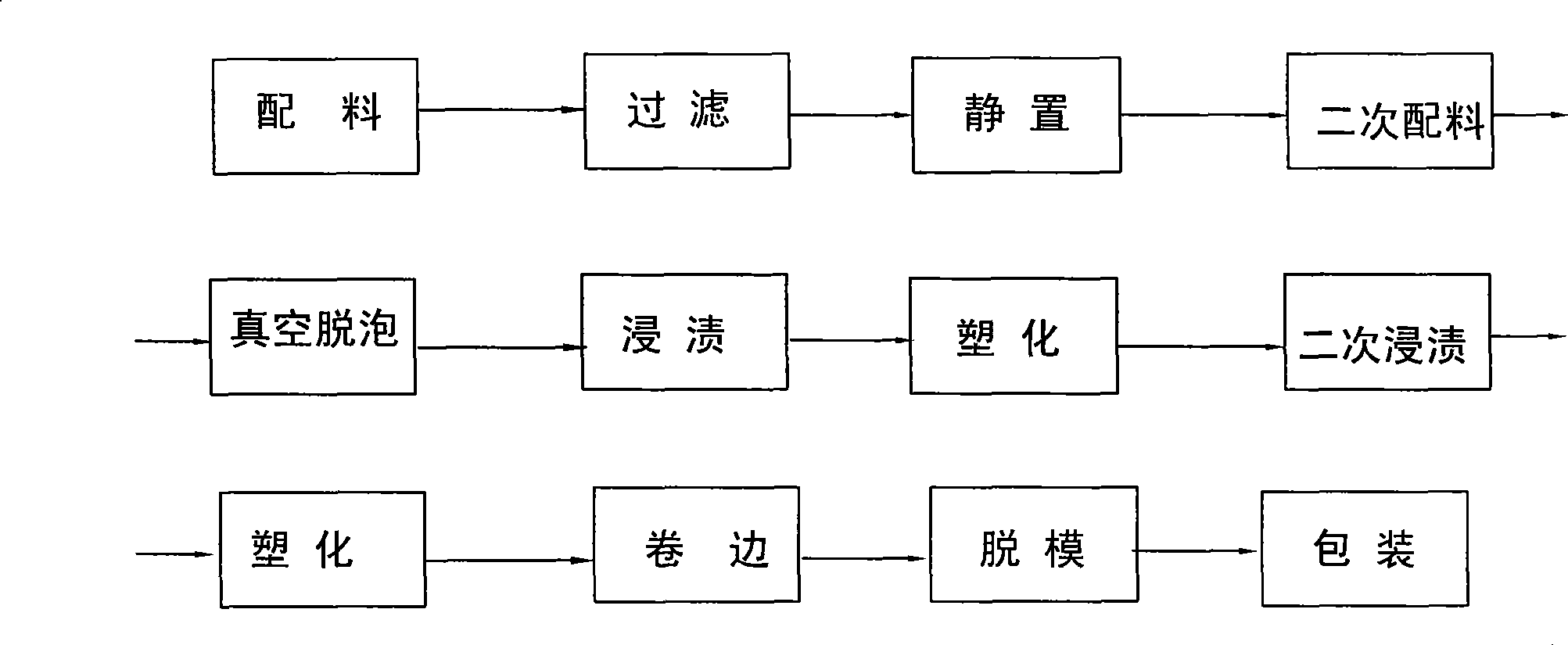

technical field [0001] The invention discloses a polyvinyl chloride (PVC) high-elasticity glove and a manufacturing method thereof, which belong to the field of plastic glove production and are products with special requirements for the elasticity of PVC gloves. Background technique [0002] The current production of PVC gloves has an elongation of ≥350% and a tensile strength of ≥11Mpa. During use, due to the influence of personal hand shape, it may not be able to cling to the arm, so it is affected by some special work. However, the price of latex gloves is too high. Contents of the invention [0003] The technical problem to be solved by the present invention is: to overcome the existing problems of the prior art, to produce a kind of highly elastic polyvinyl chloride (PVC) high-elasticity glove and its manufacturing method that can meet people's requirements for use. [0004] The technical scheme adopted by the present invention to solve its technical problems is: pol...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A41D19/00C08L27/06

Inventor 刘文静

Owner BLUE SAIL MEDICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com