Powder curing heating device for container and heating system

A technology for heating devices and containers, which is applied to the device for coating liquid on the surface, pretreatment of the surface, coating, etc. It can solve the problems of difficult to achieve simultaneous and effective curing, slow temperature rise of corner pieces and corner posts, and slow curing speed, etc., to achieve The effect of shortening the heating and curing time, fast heating speed, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The present invention will be described in detail below in conjunction with preferred embodiments, and in the accompanying drawings, the same reference numerals indicate the same parts. However, some terms are selected by the applicant according to his judgment, and their detailed meanings should be understood according to the spirit to be disclosed in the present invention.

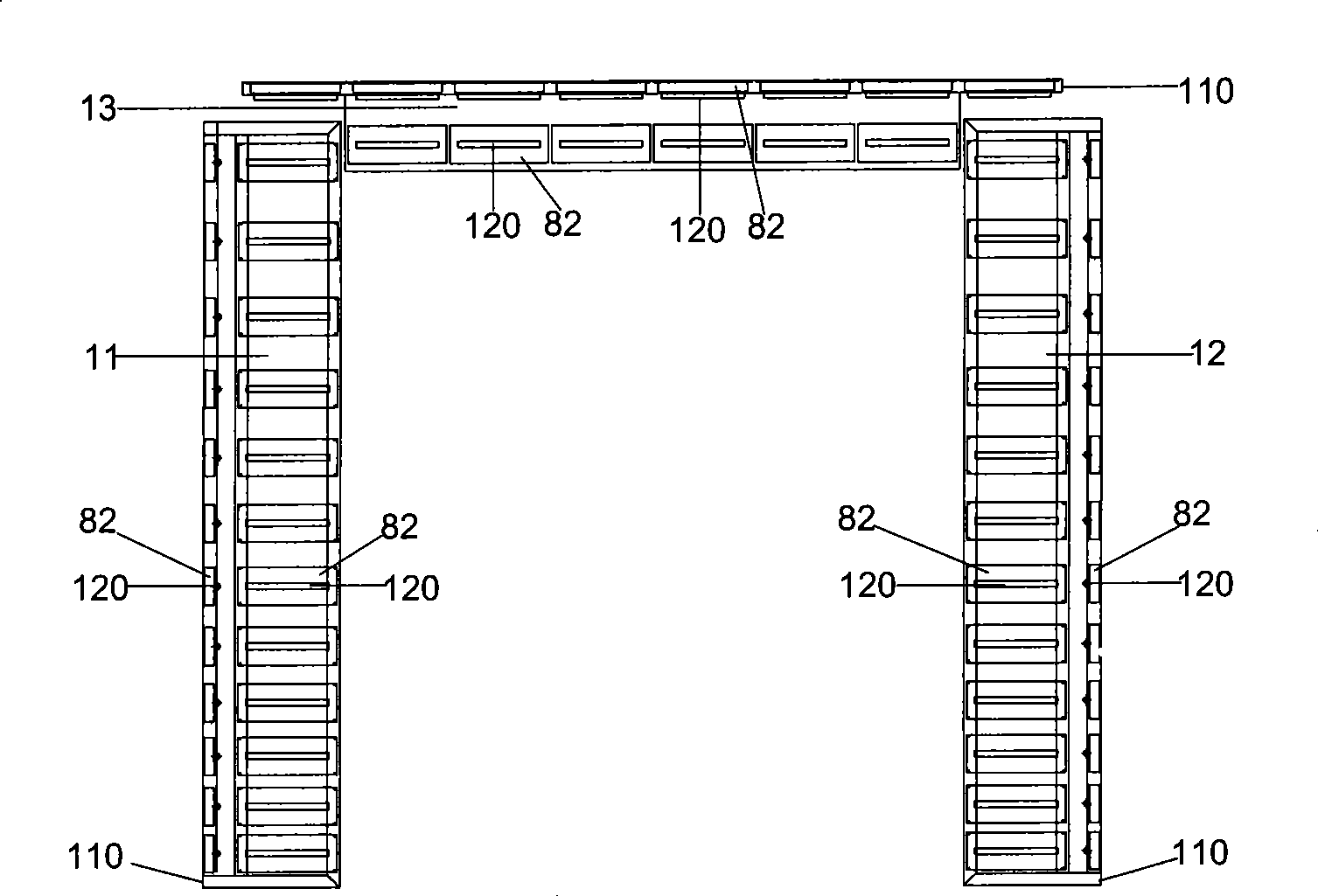

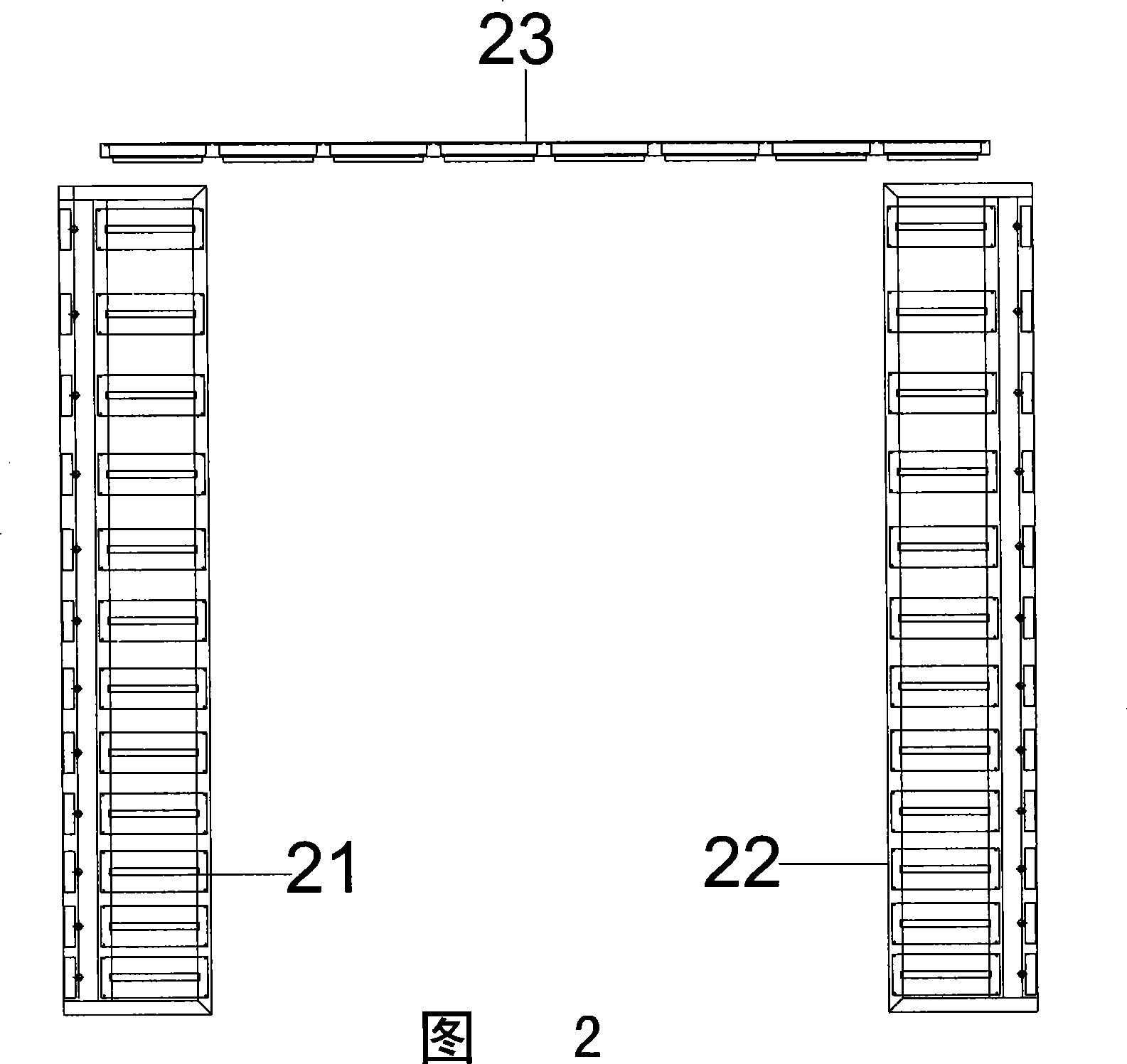

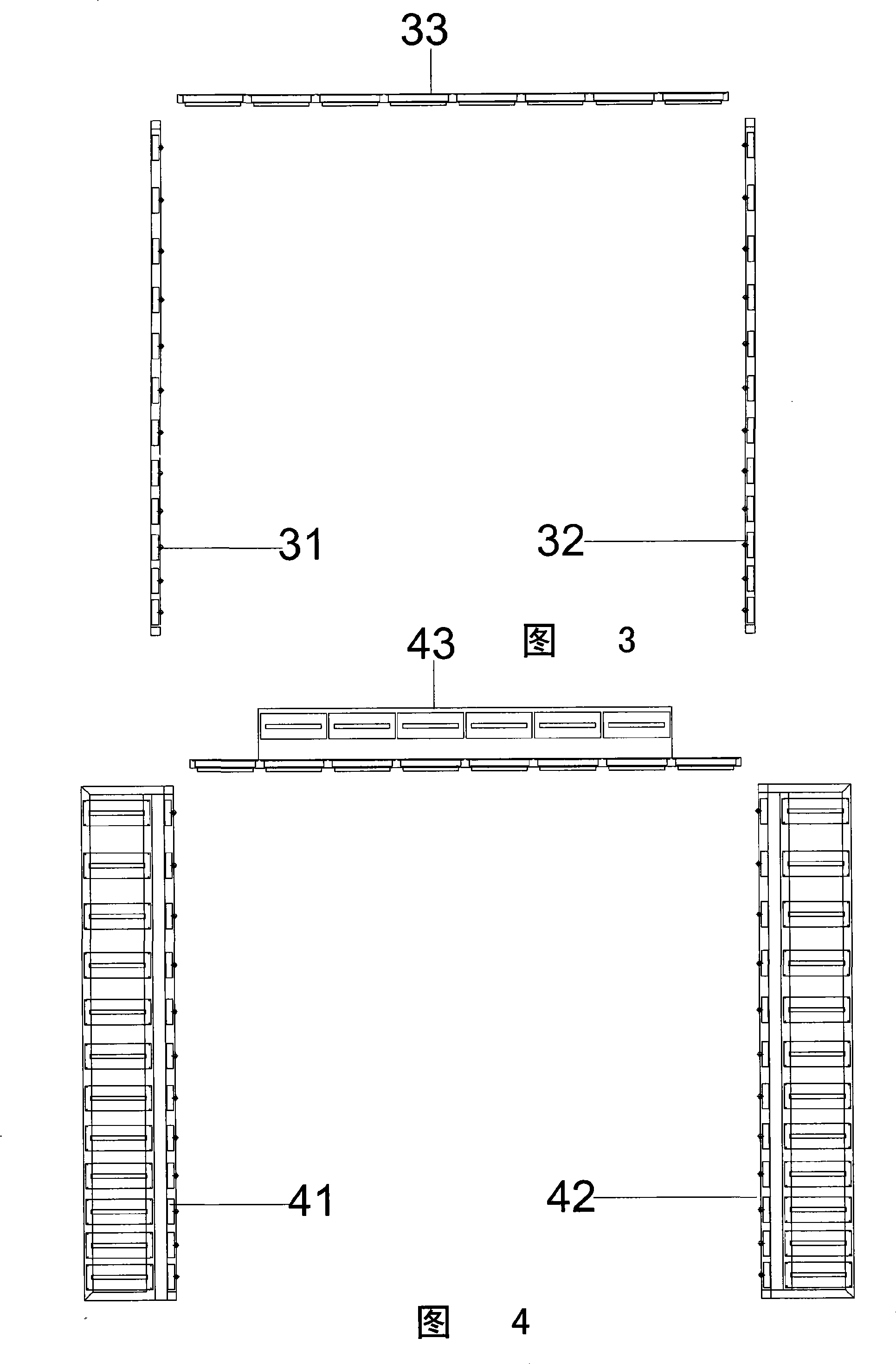

[0032] Also refer to figure 1 and Figure 8 , The first embodiment of the container powder curing heating device of the present invention includes a first heating unit 11 , a second heating unit 12 and a third heating unit 13 . The first heating unit 11 , the second heating unit 12 and the third heating unit 13 have similar structures, and the description of the structure of the first heating unit 11 is applicable to the structures of the second heating unit 12 and the third heating unit 13 . The first heating unit 11 and the second heating unit 12 are arranged in the vertical direction, and are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com