Comber nipper mechanism

A combing machine and nipper technology, which is applied in the direction of combing machines, textiles, papermaking, fiber processing, etc., can solve the problems of inability to realize constant interval carding, high noise, etc., and is beneficial to the lapping and optimization of cotton webs Control and improve the effect of production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

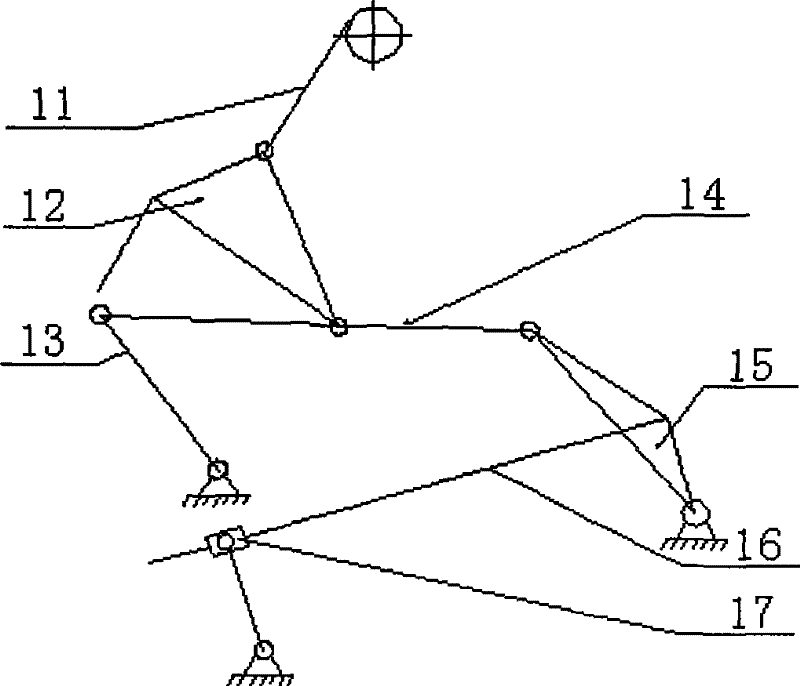

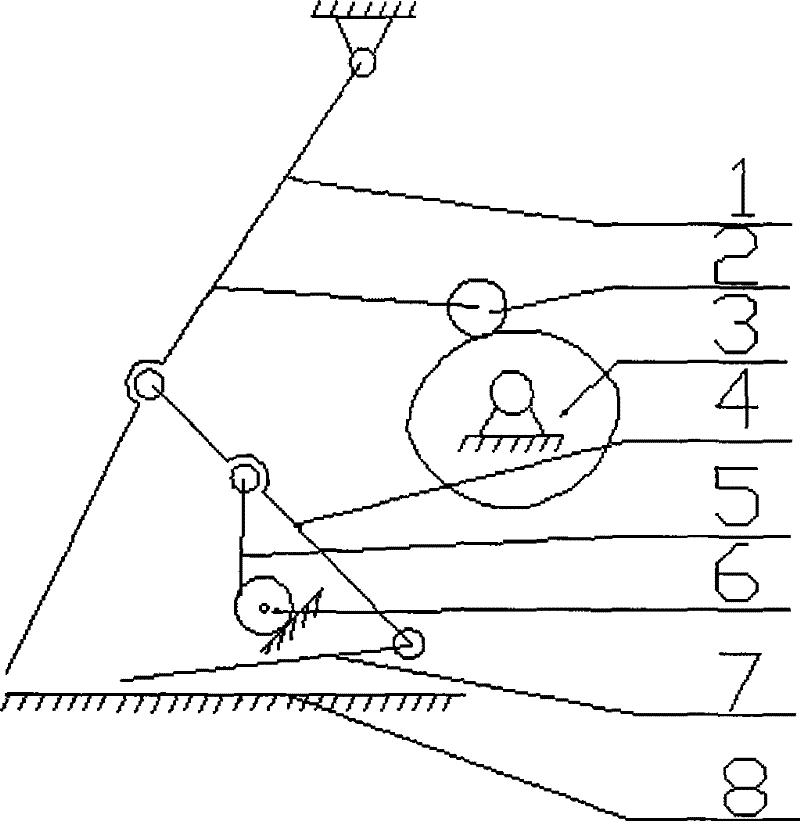

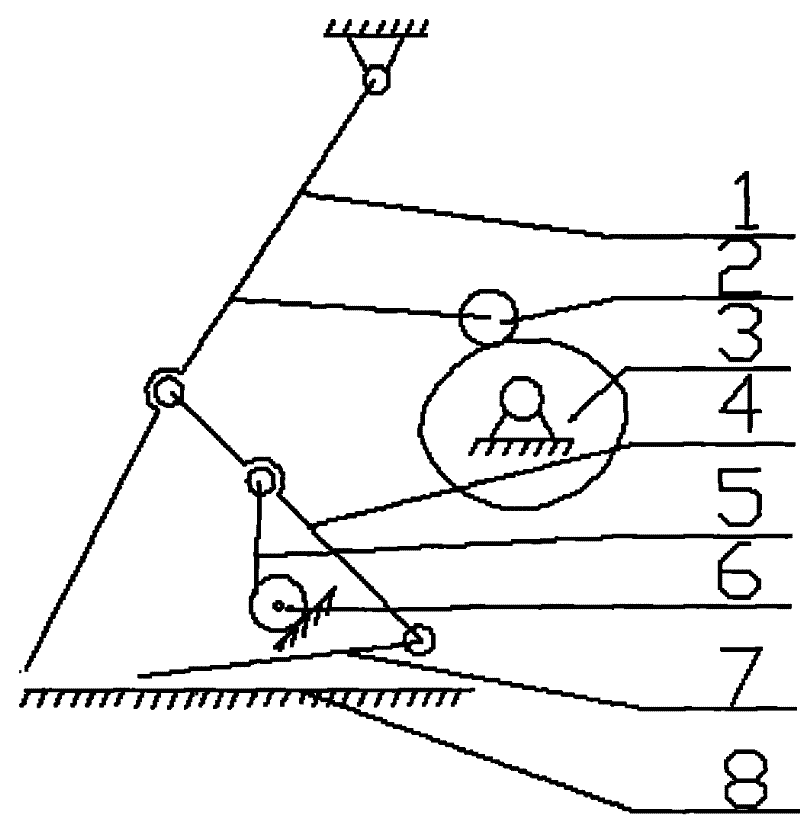

[0013] like figure 2 As shown, a combing machine nipper mechanism includes a motor-driven conjugate cam 3, a swing rod 2 is driven by a driving device 3 and fixed on an upper nipper 1, and one end of the upper nipper 1 is hinged on the frame and the other One end is movable, one end of the connecting rod 4 is hinged on the upper nipper 1 and is located between the joint of the swing rod 2 and the upper nipper 1 and the movable end of the upper nipper 1, and the other end of the connecting rod 4 is hinged to the tongue-shaped piece 7 , The middle part of the connecting rod 4 is hinged with a ratchet 5, the ratchet 5 pushes the ratchet 6 to rotate on the frame, and the lower nipper 8 is fixed on the frame.

Embodiment 2

[0015] like figure 2 As shown, a combing machine nipper mechanism includes a cam 3 driven by a servo motor, a swing rod 2 driven by a driving device 3 and fixed on an upper nipper 1, and one end of the upper nipper 1 is hinged on the frame and the other One end is movable, one end of the connecting rod 4 is hinged on the upper nipper 1 and is located between the joint of the swing rod 2 and the upper nipper 1 and the movable end of the upper nipper 1, and the other end of the connecting rod 4 is hinged to the tongue-shaped piece 7 , The middle part of the connecting rod 4 is hinged with a ratchet 5, the ratchet 5 pushes the ratchet 6 to rotate on the frame, and the lower nipper 8 is fixed on the frame.

[0016] When the present invention is in use, the tongue-shaped piece 7 is linked with the upper nipper 1 . When the upper nipper 1 is opened, the tongue-shaped piece 7 moves to the separating roller, and the cotton web is transported forward, so that the carded cotton web is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com