Vertical shaft giant energy and energy-collecting wind-power water drawing machine

A wind turbine and vertical shaft technology, which is applied in the field of new vertical shaft wind water lifting units, can solve the problems of low active control ability, difficult driving, and difficult effective application, etc., and achieve the effect of realizing the design level of the output capacity of a single machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

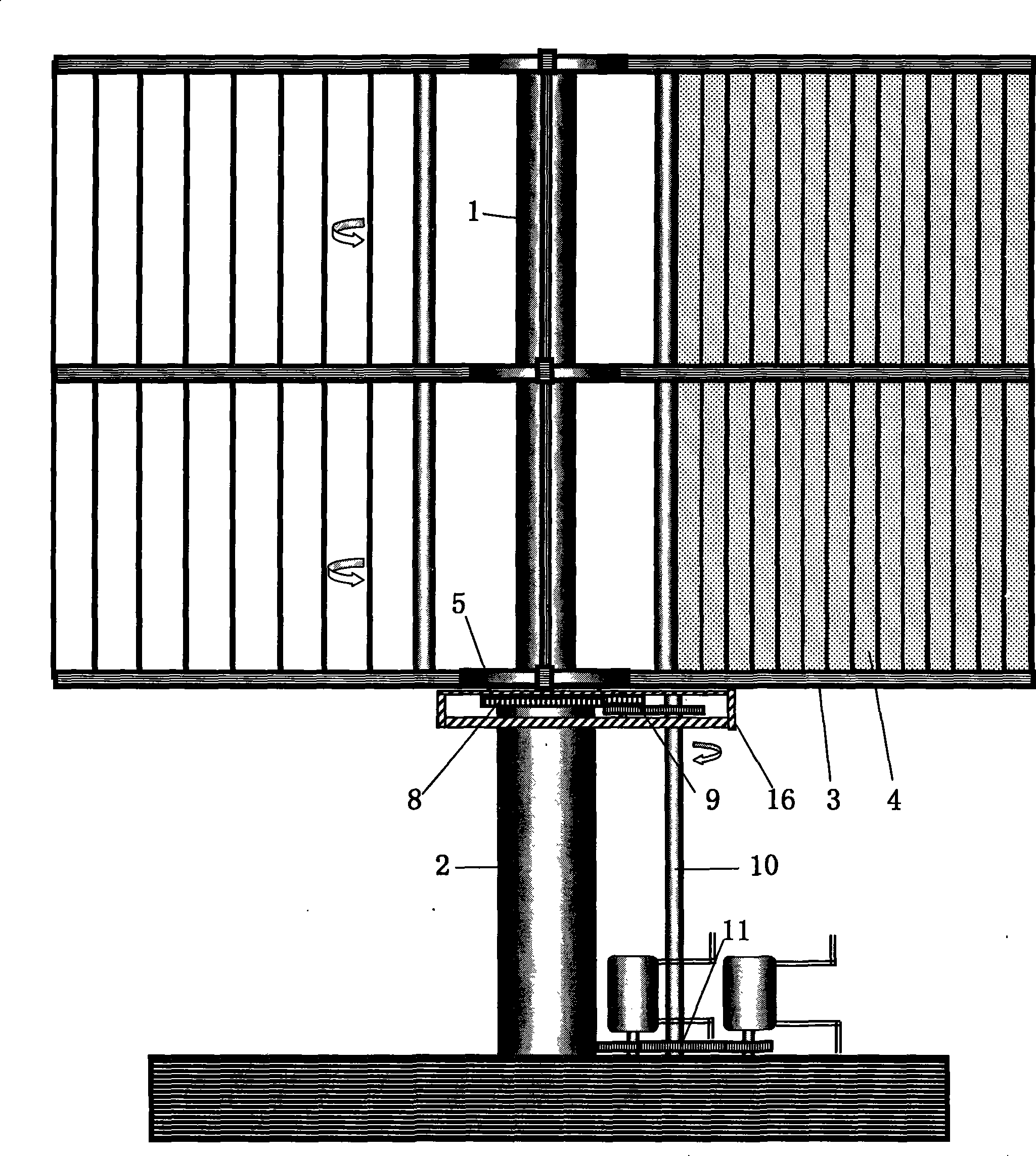

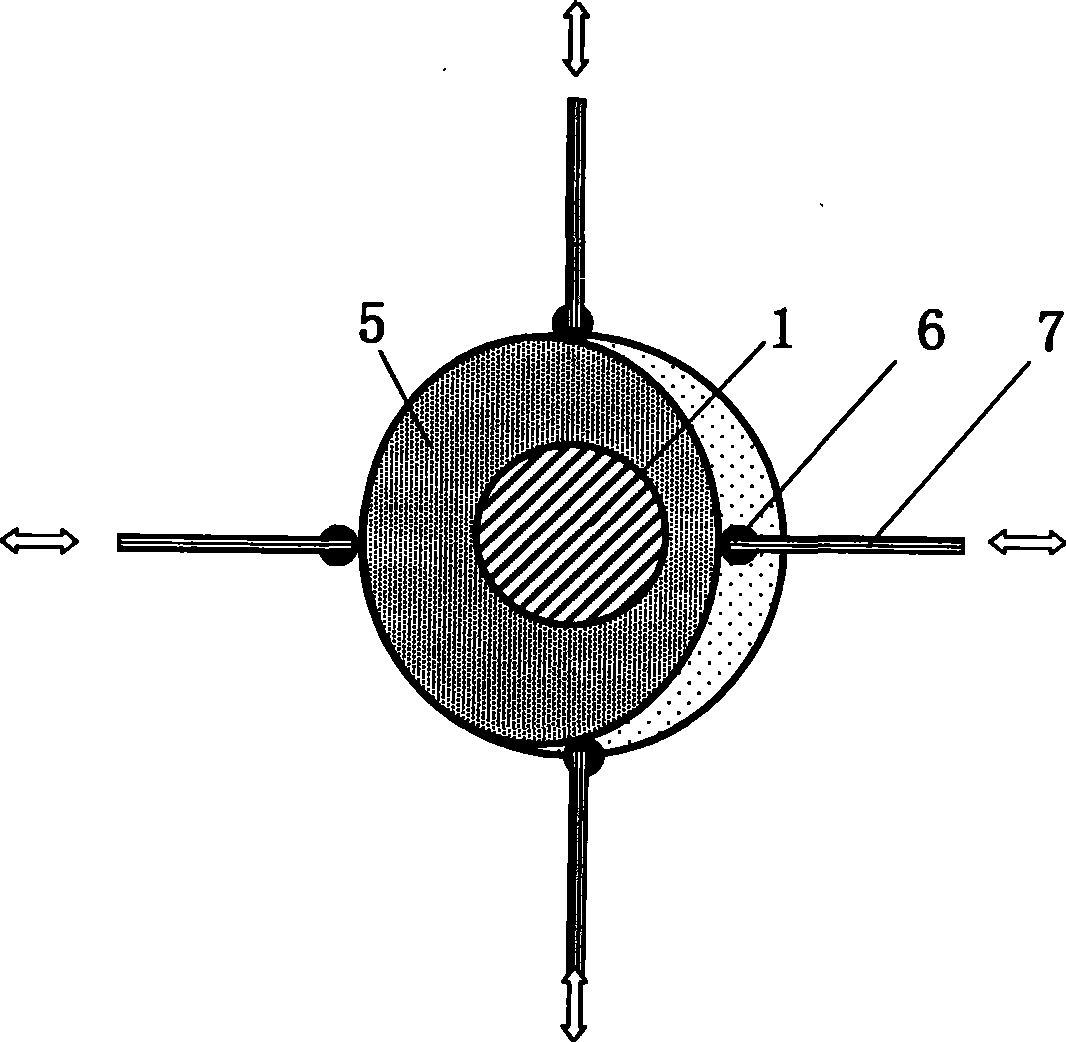

[0029] combine figure 1 , 2 , 6) It can be seen that when the vertical axis giant energy wind-driven water lifting unit is working against the wind, it first needs to measure the direction of the wind force, and then determine and adjust the direction of the flat part of the wind-facing guide rail disk 5 according to the direction of the wind force, so that it can reach the operating position of each rotating wind force plate 3 At the same time, the windward inverter plate 4 on it is closed due to the cooperative drive of the rolling wheel 6 and the push-pull rod 7, and the direction of the convex part of the windward guide rail disk 5 can make the operating position of the rotating wind force plate 3 in place and then unfold. The installed push-pull spring realizes the reset, and when it is close to the downwind windward angle, the windward inverter board gradually expands, and gradually shrinks after reaching the vertical wind direction.

[0030] Through the above process,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com