Light guide plate of backlight unit with patterns

A backlight unit and light guide plate technology, applied in light guides, optical components, optics, etc., can solve problems such as reduced productivity, uneven light scattering, screen moiré, etc., to prevent the appearance of dark lines, prevent poor appearance, and reduce changes volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Referring to the accompanying drawings, the light guide plate of the backlight unit provided with graphics of the present invention will be described in detail.

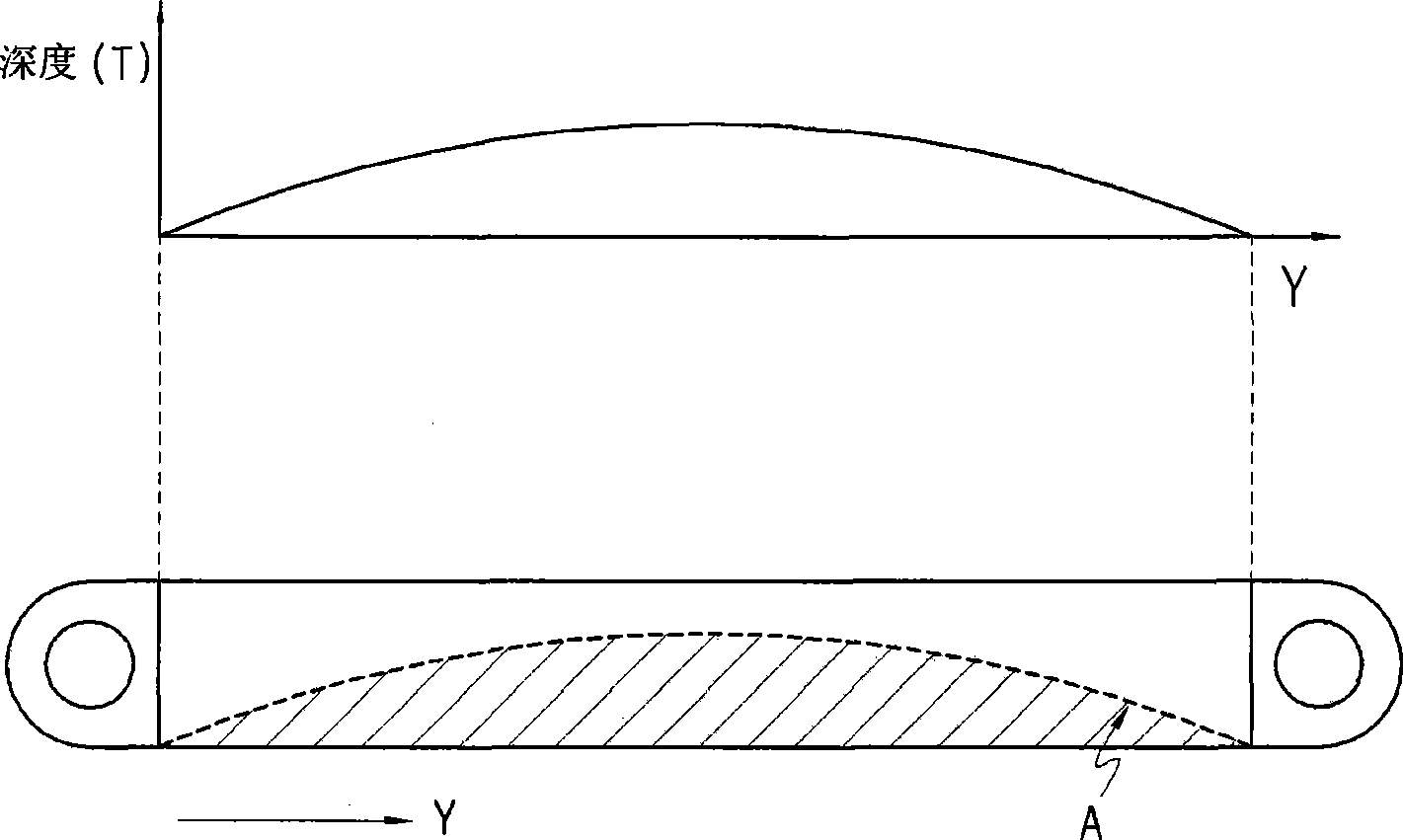

[0045] Figure 2a It is a sectional view of the backlight unit light guide plate provided with graphics of the present invention, Figure 2b yes means Figure 2a Diagram of the graphic depth profile in the light guide profile shown.

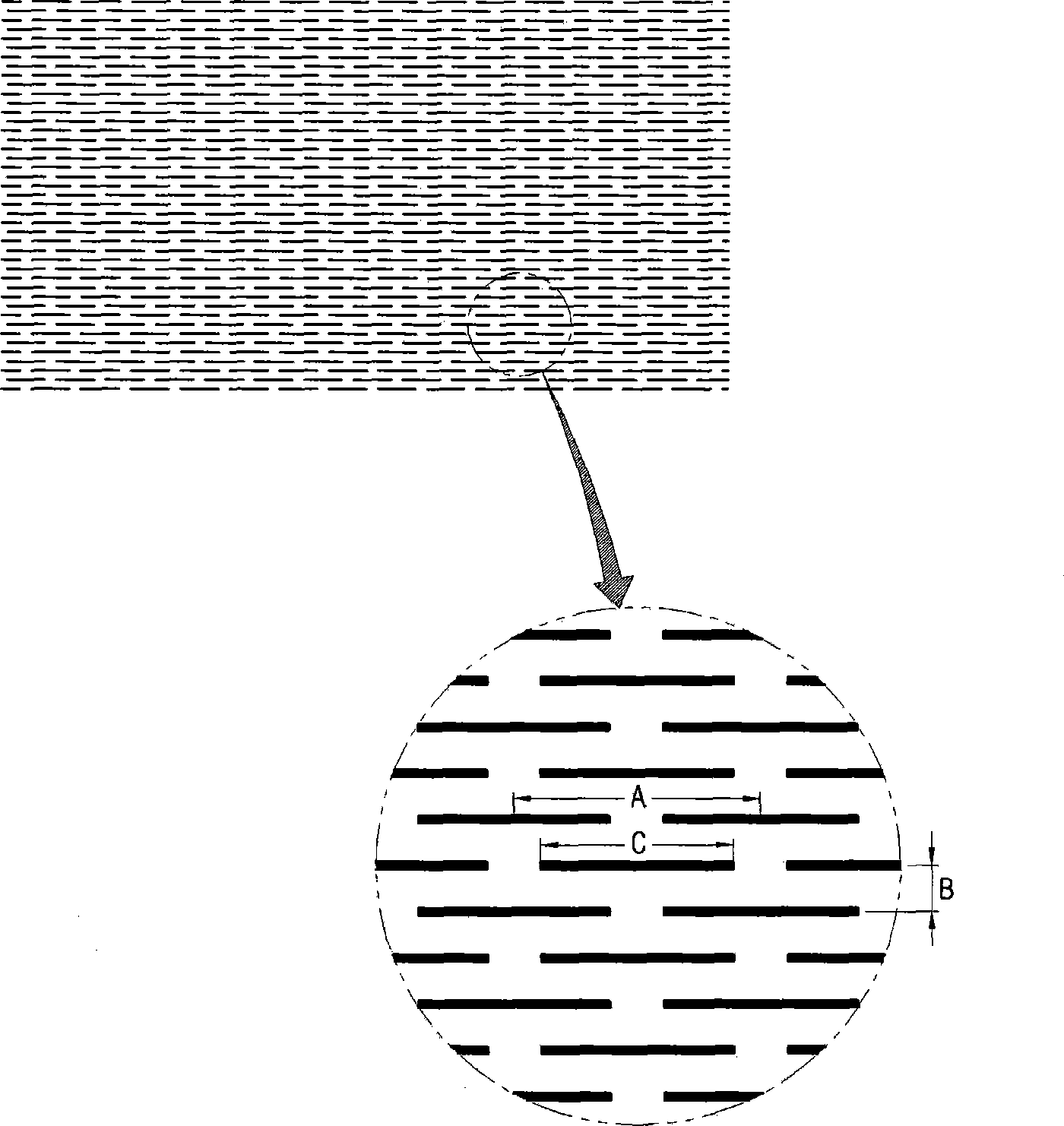

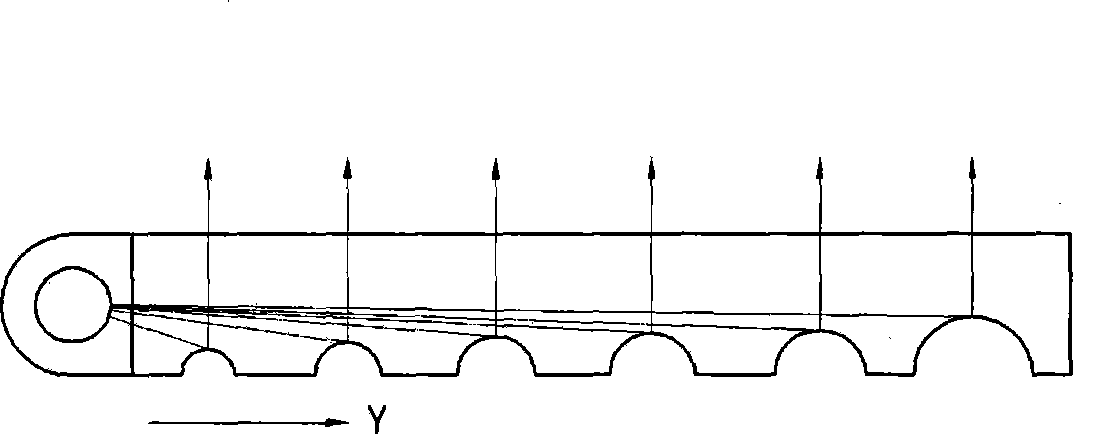

[0046] Such as Figure 2a As shown, the depth of the pattern formed by the patterning method of the light guide plate of the backlight unit provided with the pattern of the present invention has a contour line that changes as the distance from the light source, that is, the Y coordinate increases, so that the light emitted from the light source is reflected have the same brightness. In addition, the individual figures each have an engraved oval shape.

[0047] the above Figure 2a In , if the light source is set at both ends of the Y-axis of the light guide plate, such as F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com