Boot for constant velocity universal joint

A constant velocity universal joint and protective cover technology, applied in the direction of elastic coupling, engine seal, engine components, etc., can solve the problems such as the offset of the protective cover belt and the large deformation of the wrinkle part, so as to prevent the axial direction deviation. The effect of shifting and preventing ear interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

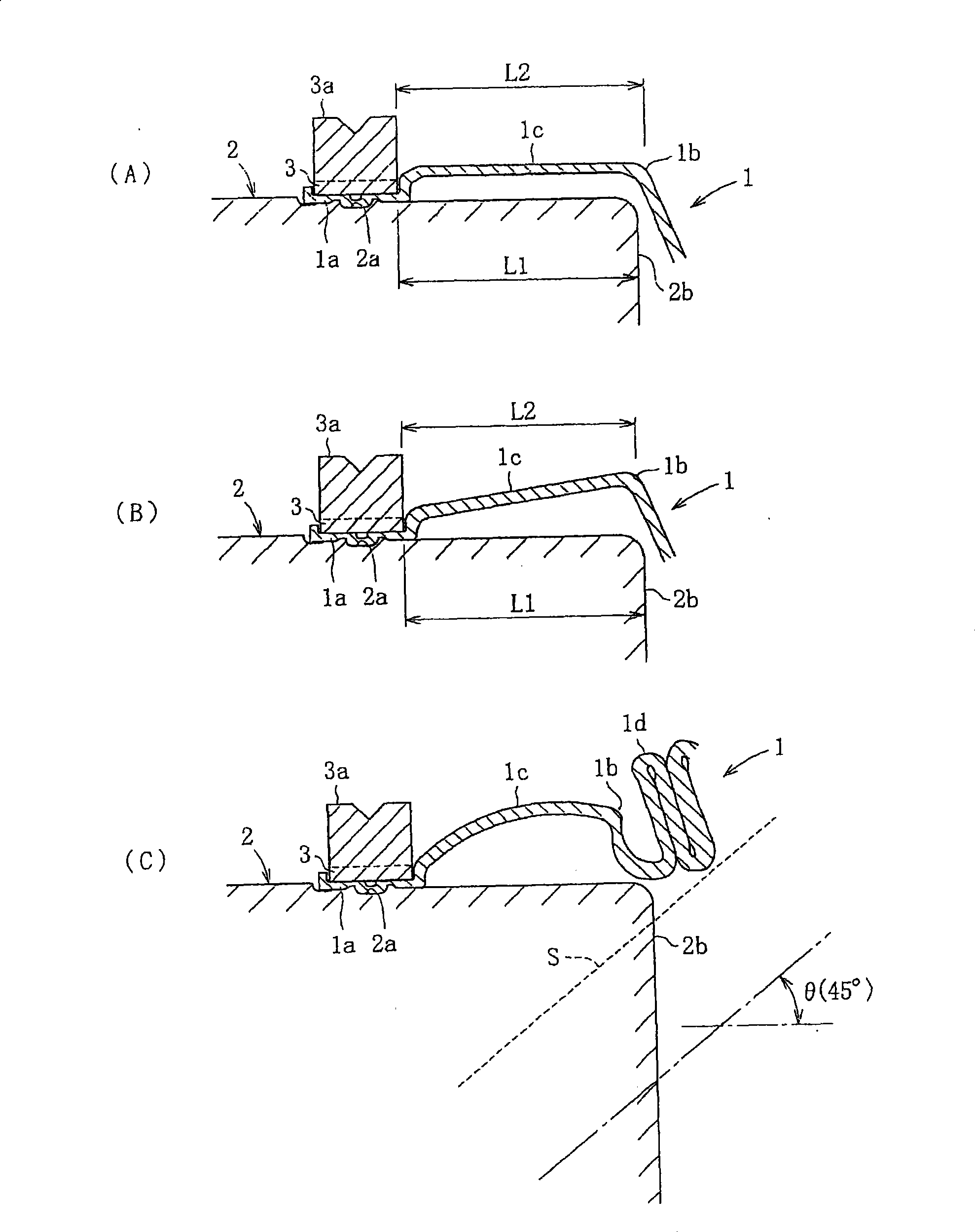

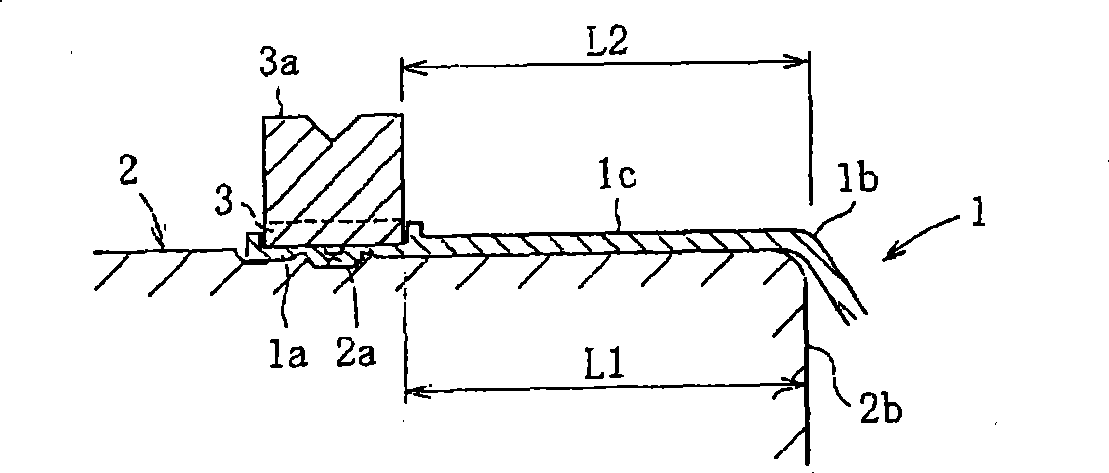

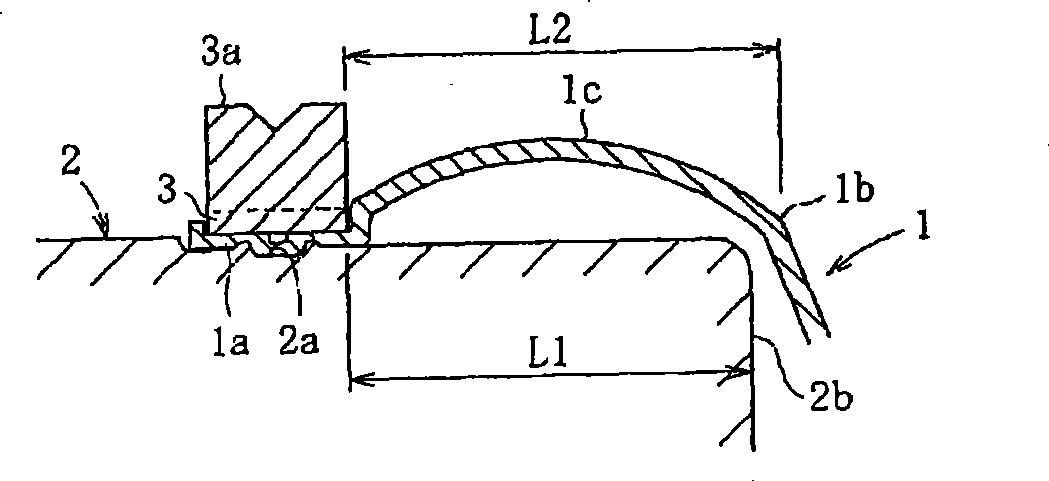

[0031] Below, according to Figure 1 to Figure 8 Embodiments of the present invention will be described.

[0032] figure 1 A cross-section of a large-diameter portion of the boot 1 for a constant velocity universal joint according to the first embodiment of the present invention is shown. The overall shape of the boot 1 is almost the same as that of the conventional one, consisting of a large-diameter portion 1a fixed on the outer peripheral surface of the outer joint member (outer ring 2) of the constant velocity universal joint, and a small-diameter portion 1a fixed on the outer peripheral surface of the shaft of the constant velocity universal joint. A protective cover 1 is formed by a corrugated portion (not shown) and a corrugated portion (not shown) connecting the large diameter portion and the small diameter portion. The wrinkle part consists of about 2 to 7 mountains and valleys between them. The protective cover 1 is molded from a rubber material such as neoprene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com