A kind of medical bracket and its manufacturing method

A manufacturing method and technology for a stent body, which are applied in the field of medical stents, can solve the problems of inflammation, decrease in stent flexibility, increase in stent manufacturing cost and manufacturing time, and achieve the effect of reducing foreign body sensation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

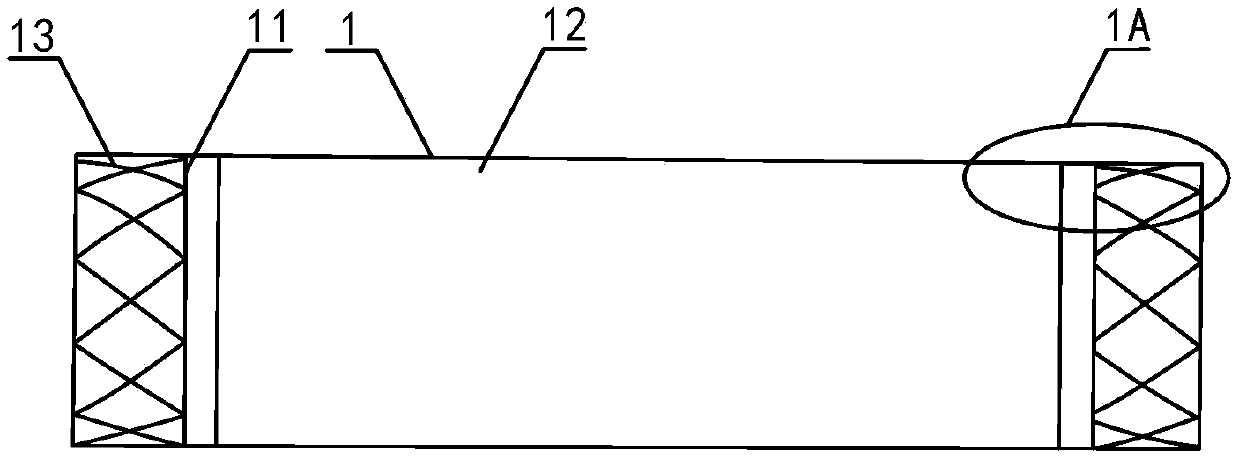

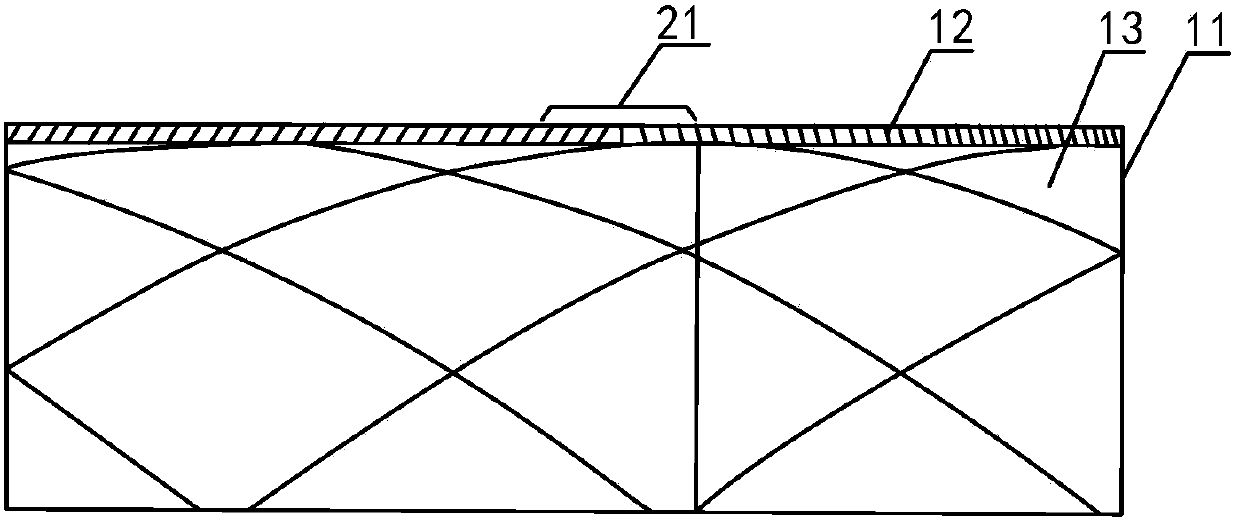

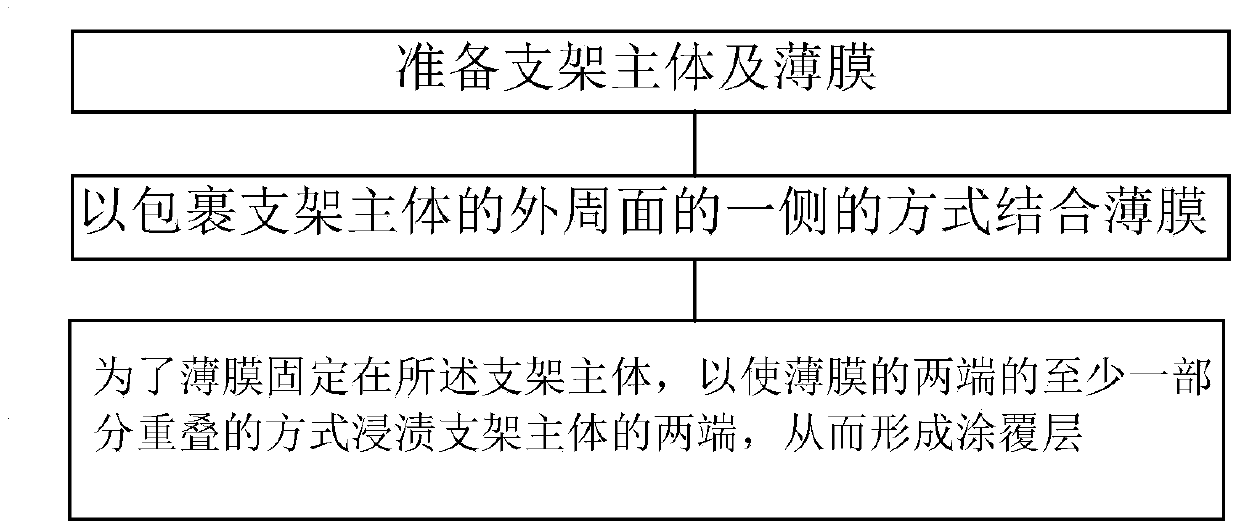

[0038] Such as Figure 1-2 As shown, the medical stent according to the embodiment of the present invention includes a stent body 1, and the stent body 1 is composed of a main body 11, a film 12 and a coating layer 13. The periphery of the stent body 1 is equipped with a hollow cavity and the hollow Several holes are formed inside the cavity by crossing multiple lines or laser patterns, so that it is easy to compress or expand. This structure forms a space where the inner wall can be stably expanded when the narrow part is located, and at the same time, the body fluid can move smoothly; The peripheral cross-section of the stent body 1 is formed in a circular shape as a whole, and since there are no corners and corners, no stimulation will be generated at the installation site of the stent body 1 .

[0039] Correspondingly, the outer surface of the main body part 11 is wrapped with a layer of film 12 and blocks the multiple holes of the bracket body 1. As for the film 12, as lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com