Vertical full-rotation shuttle

A full rotary hook, vertical technology, used in textiles and papermaking, sewing equipment, ferrule mechanism for sewing machines, etc., can solve problems such as yarn breakage and winding, and achieve the effect of preventing yarn breakage and yarn winding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

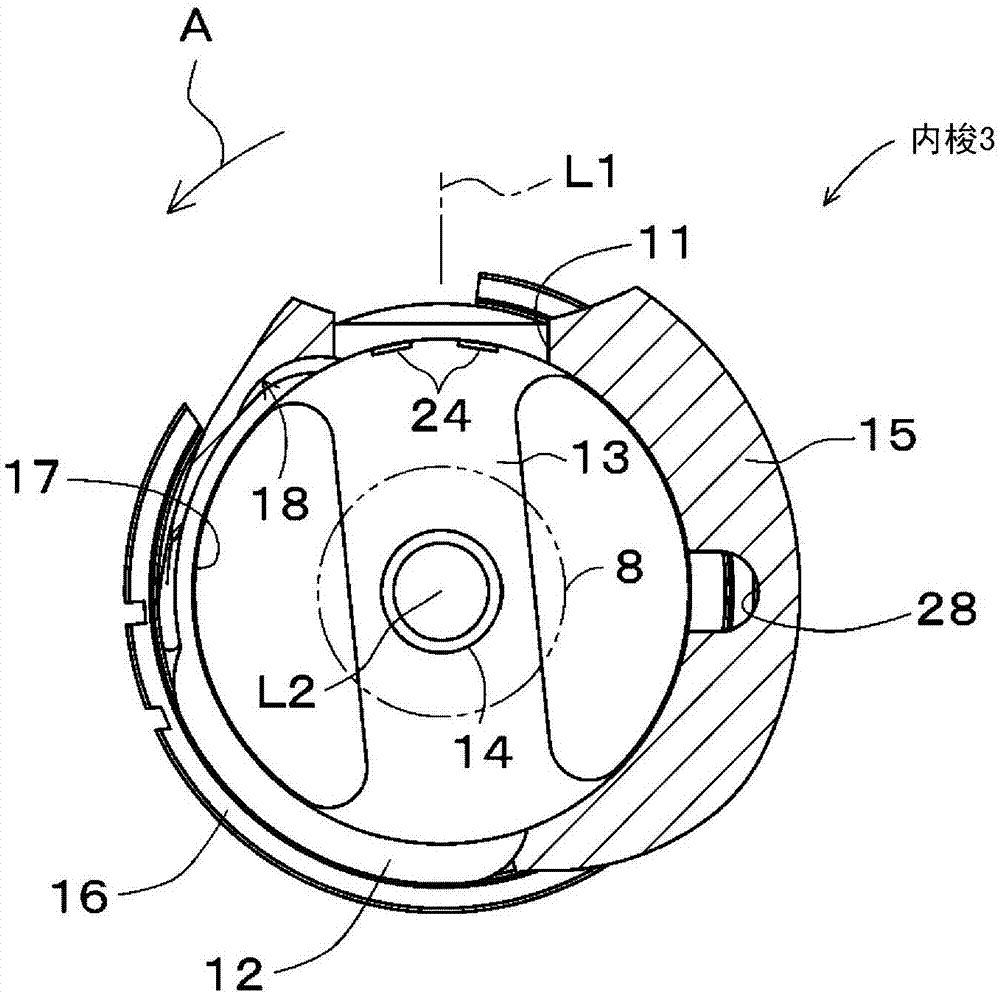

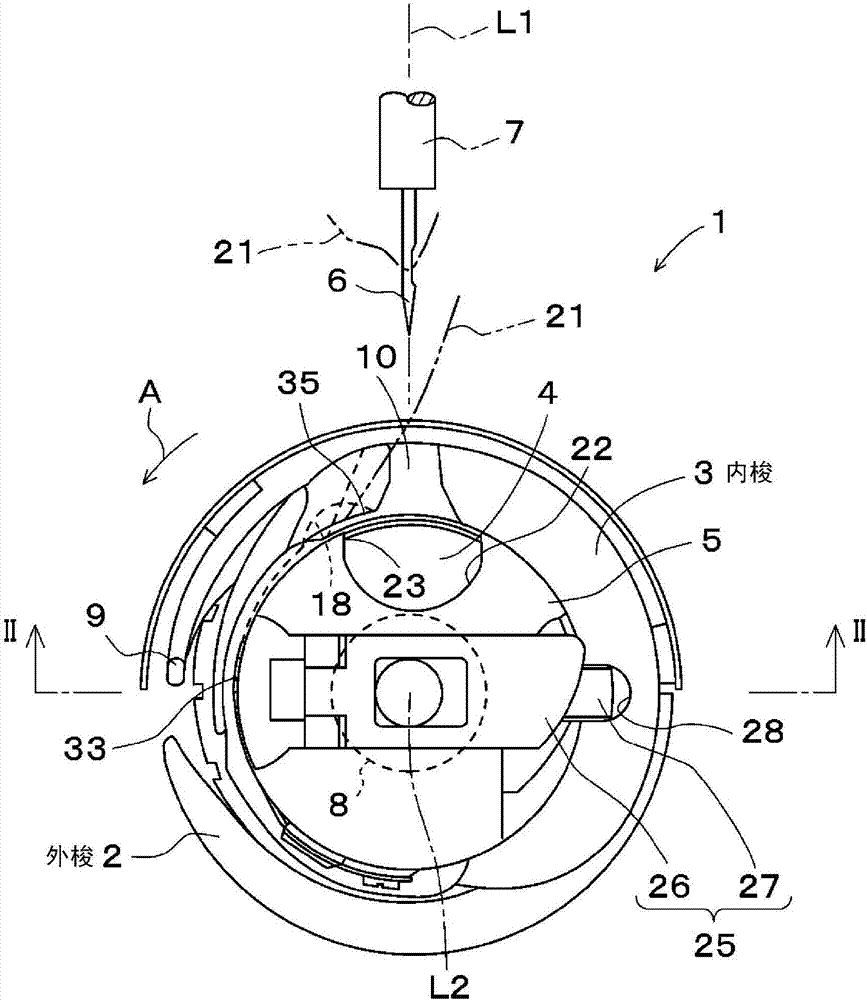

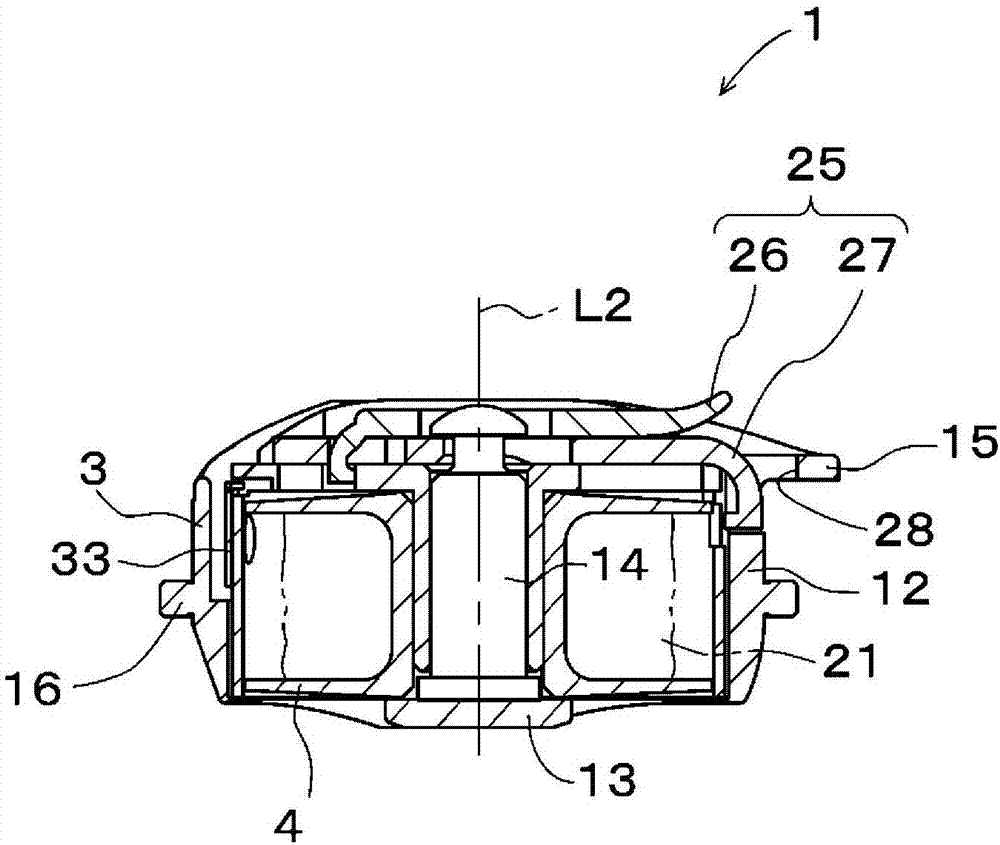

[0052] figure 1 It is a cross-sectional view of the inner hook 3 included in the vertical full rotary hook 1 according to one embodiment of the present invention viewed from the front side, figure 2 is the front view of vertical rotary hook 1, image 3 for from figure 2 The sectional view of the vertical full rotary hook 1 is seen on the section line II-II. Figure 4 It is a three-dimensional view of inner shuttle 3, Figure 5 It is the left side view of inner shuttle 3. figure 1 means from Figure 5 The section line I-I of the section line I-I sees the section of inner shuttle 3.

[0053] The vertical full-rotating hook 1 of this embodiment includes an outer hook 2 , an inner hook 3 , a bobbin 4 and a bobbin case 5 . The outer shuttle 2 is fixed to a lower shaft 8 that is rotationally driven in the direction of arrow A around a rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com