Bunker for collecting solid castoff in industrial production process and operation method thereof

A solid waste collection hopper technology, applied to the operation of the collection hopper, in the field of solid waste collection hoppers in industrial production processes, can solve problems that have not been solved well, improve environmental cleanliness, reduce labor intensity, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: The opening and closing structure of the gate.

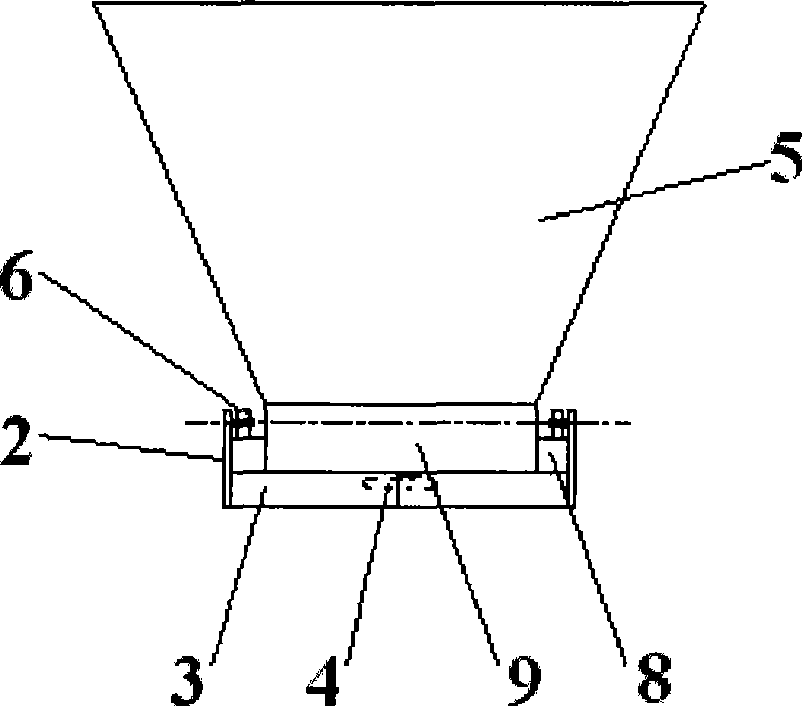

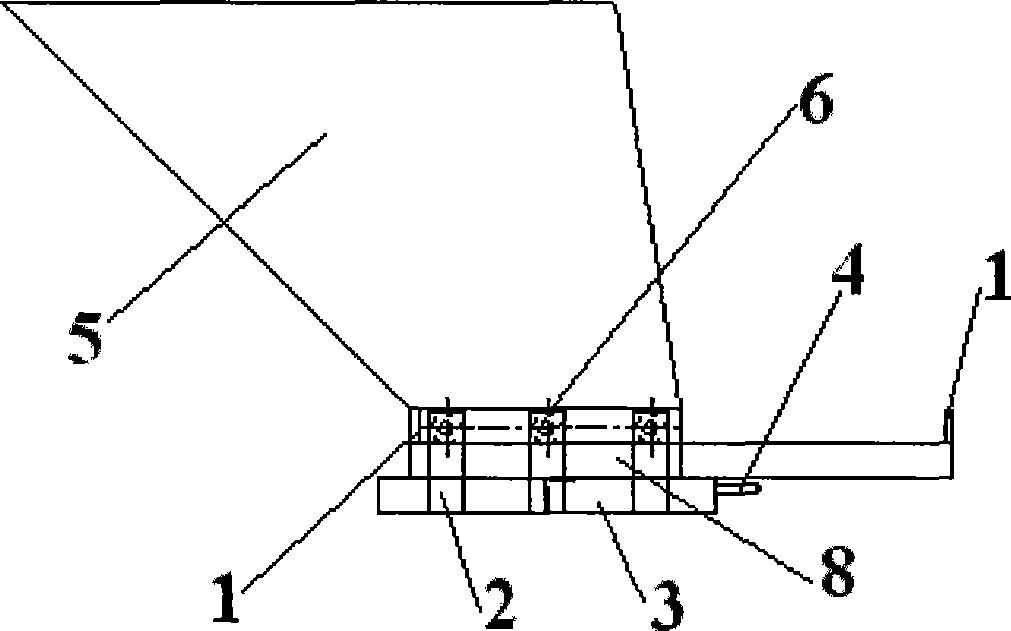

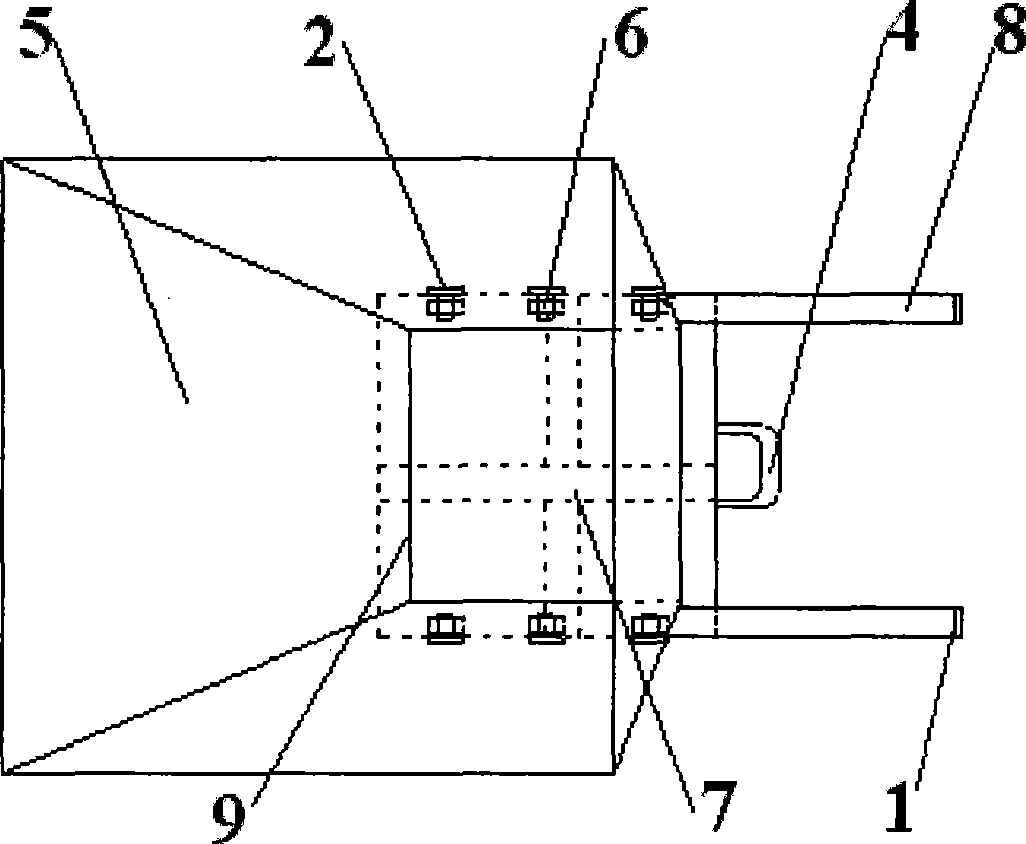

[0046] Such as figure 1 and figure 2 As shown, the gate 3 adopts a sliding switch device, which makes the gate 3 slide horizontally in the process of opening or closing. A rail-shaped rolling wheel platform 8 is arranged in the horizontal direction, and the described rolling wheel 6 rolls in the length direction of the rolling wheel platform 8 .

[0047] Due to the heavy weight of the waste in the collection hopper, in order to reduce the sliding resistance of the gate 3, the above-mentioned opening and closing structure is adopted. Its structure is that two rolling wheel platforms 8 are welded horizontally on both sides of the funnel neck 9, so the rolling wheels 6 connected to the gate 3 can roll on the rolling wheel platforms 8 to realize horizontal movement with very little frictional resistance. The lower mouth of the collecting hopper can be opened and closed very conveniently. As long as the oper...

Embodiment 2

[0048] Embodiment 2: Gate handle structure.

[0049] Such as Figure 1 to Figure 3 As shown, the gate 3 is provided with a gate handle 4 on one side of the opening direction, and when opening or closing, it is carried out through the gate handle 4 . In this way, the gate 3 is more convenient to operate.

Embodiment 3

[0050] Embodiment 3: Gate strengthening structure.

[0051] Because the gate is made of thin board material, in order to make it bear a certain weight, such as image 3 As shown, the gate 3 is provided with a gate reinforcement rib 7 on its downward facing side and is connected to its frame.

[0052] The gate reinforcing rib 7 is arranged on the lower surface of the gate 3 in order to increase the strength of the gate 3, increase the load-bearing capacity and prevent deformation. Its structure can be the same as that in the figure, adopting the rib form of " ten "; If the area of gate 3 is bigger, also can adopt " well " shape, or adopt the structure of " rice " shape. Or adopt other layout forms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com