Cantilever beam external anchor stayed-cable bridge

A technology for cable-stayed bridges and suspension beams, applied in the direction of cable-stayed bridges, bridges, bridge parts, etc., can solve the problems of unfavorable long-term development and utilization of river hydraulic power, increased investment costs of bridge construction materials, difficulty in selection and construction operations, etc., to achieve Conducive to long-term development and utilization, saving bridge construction materials, reducing materials and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific structure of the suspension beam external anchor cable-stayed bridge of the present invention is further described in conjunction with the accompanying drawings and embodiments, and its features and advantages are more clear.

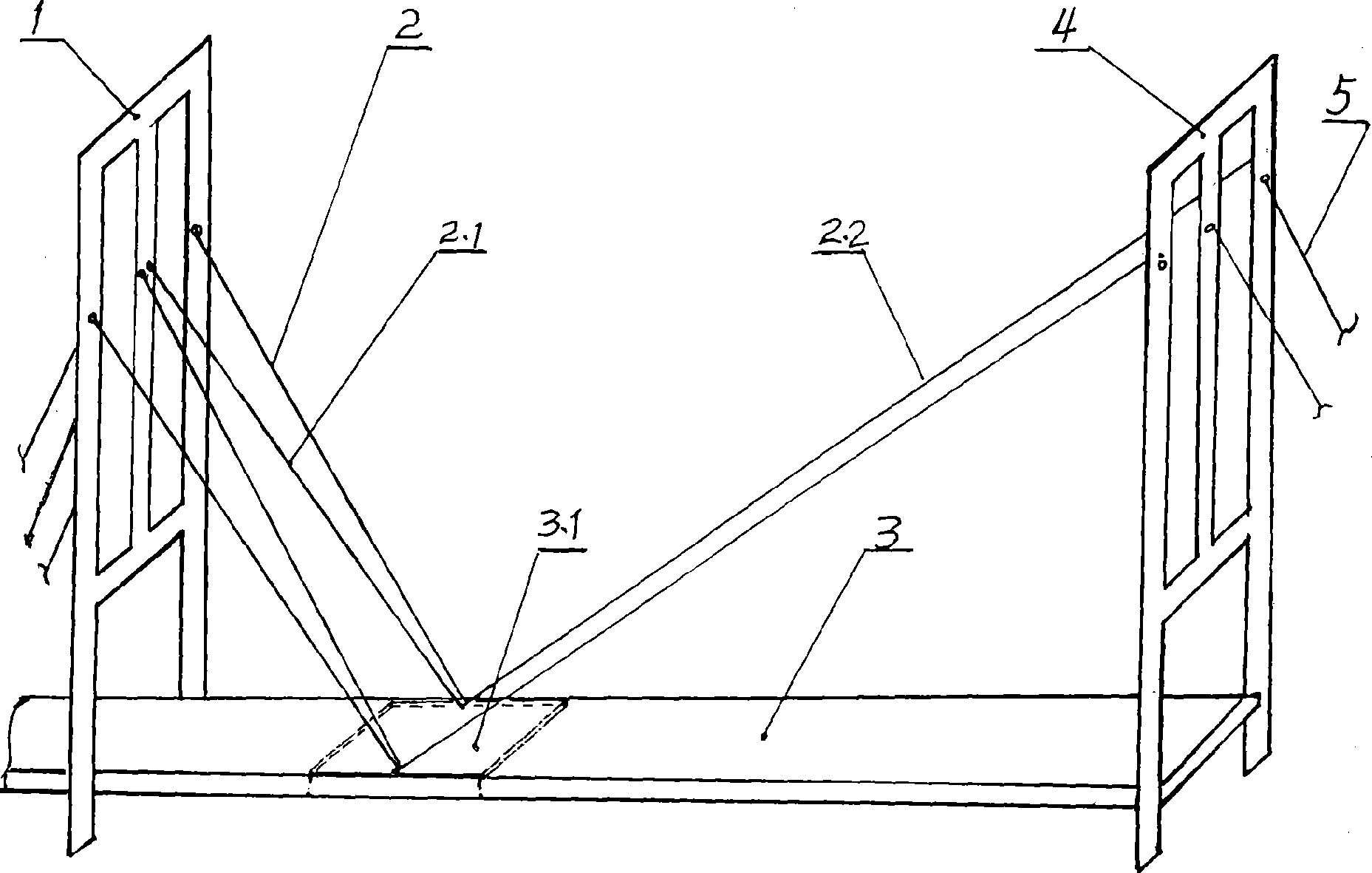

[0011] Embodiment 1 of the suspension beam external anchor cable-stayed bridge of the present invention, see figure 1 , its structure includes: cable tower 1, stay cable 2, main beam 3, each middle cable tower 1 is connected to main beam 3 on both sides through stay cable 2 on both sides, and each unit main beam 3.1 is respectively connected to the adjacent Stay cables are involved between the two pair of cable towers 1 and 4, and outer anchor cables 5 are set on the outermost two pair of cable towers 4 for connecting with ground anchor piles (not shown) at the bridge head.

[0012] Embodiment 2 of the suspension beam external anchor cable-stayed bridge of the present invention, see figure 1 , its structure includes: in the structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com