Cart for storing tire second stage building tire blank

A technology for storing vehicles and green tires, which is applied in the field of storage and transportation of second-stage formed tire blanks for tires and giant engineering tires. Affect tire quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

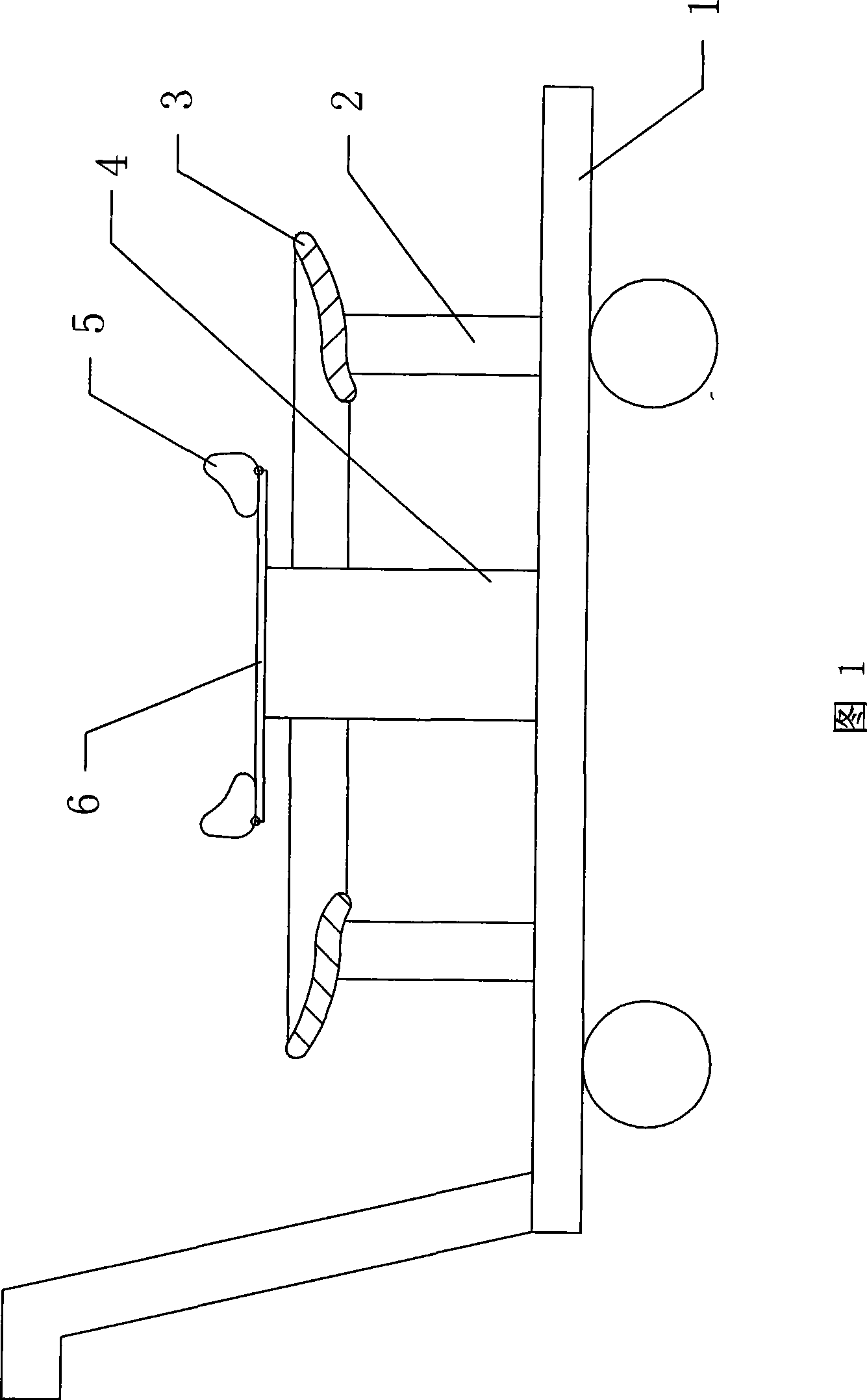

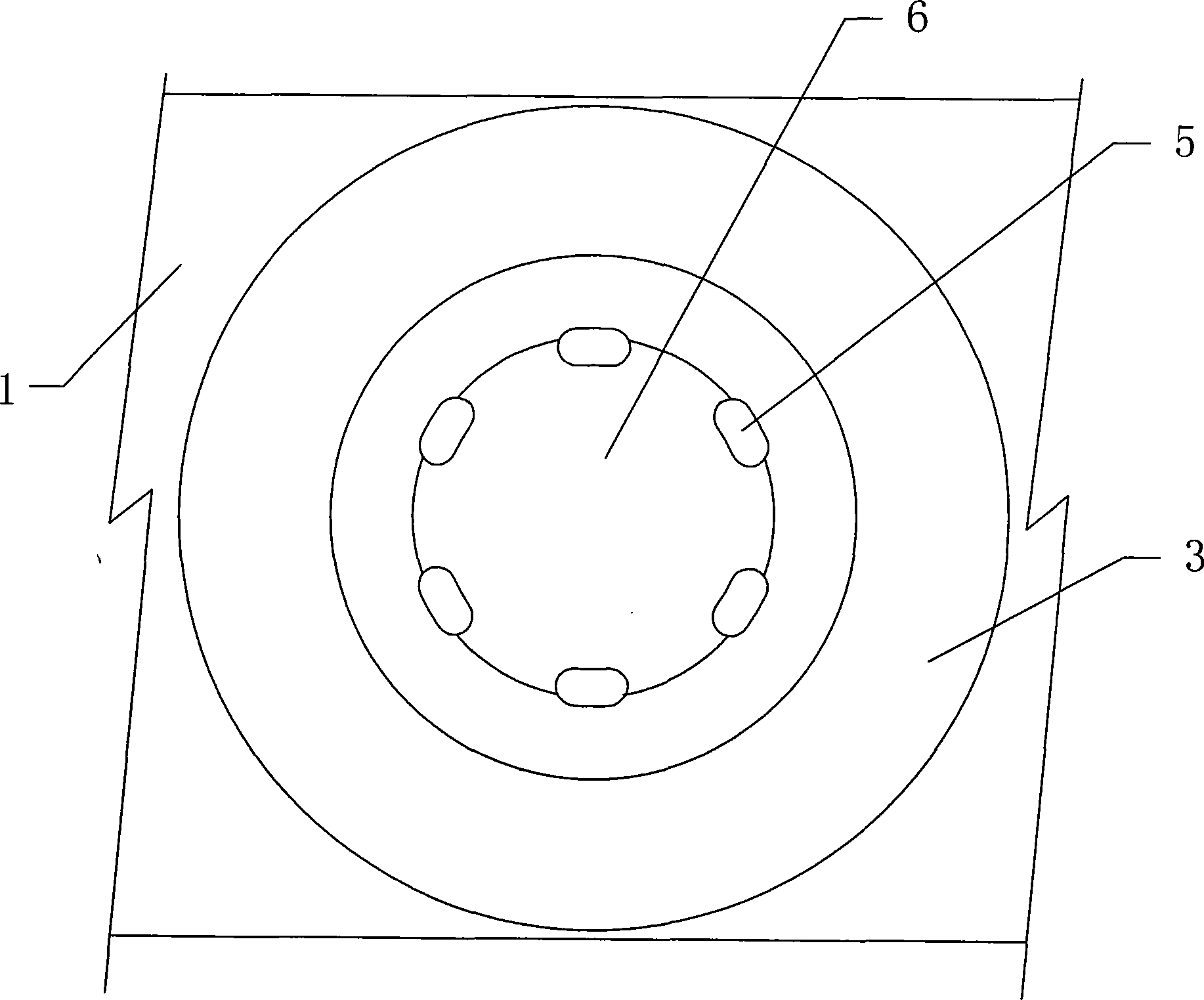

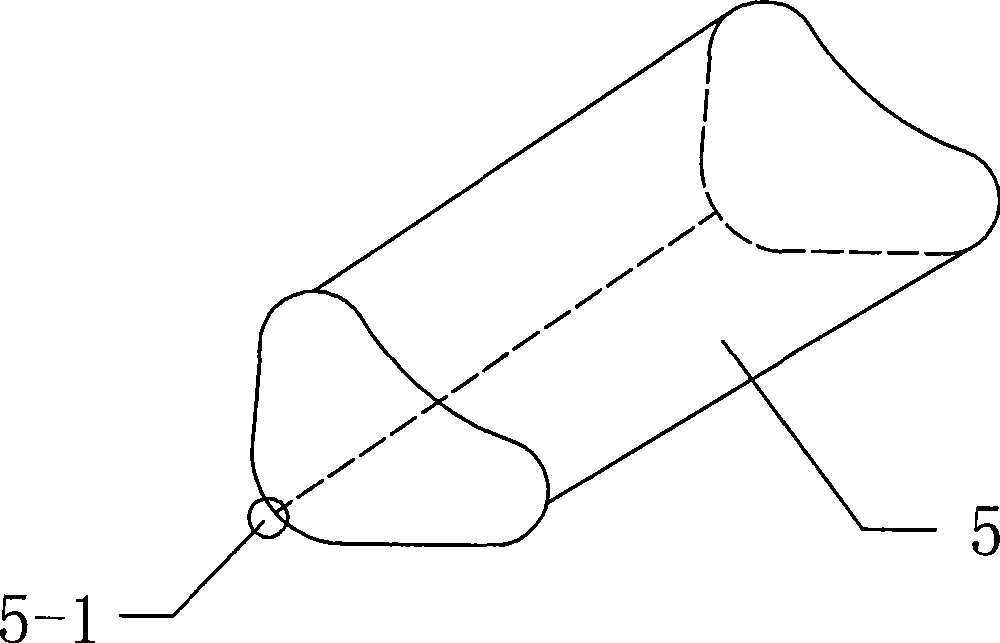

[0016] The structure of the embodiment of the two-segment molded tire storage vehicle of the present invention is shown in Figures 1 and 2. The vehicle body 1 equipped with the pneumatic tire walking roller is fixedly equipped with a bracket 2, and the bracket 2 is fixed to and supports the annular tray 3 on it. , The diameter of the inner hole of the tray 3 is greater than the diameter of the green tire bead, and its outer diameter is equal to or greater than the outer diameter of the green tire. The height of the bracket 2 is greater than the height of the lower spigot of the green tire. The bracket 2 is composed of 4 pillars, and the inner diameter of the ring formed by the pillars is larger than the diameter of the bead of the green tire 7. A lifting mechanism 4 is installed on the car body 1 under the inner hole of the tray 3. The lifting mechanism 4 is a hydraulic mechanism. The top of the piston rod is fixed with a circular bracket 6. The diameter of the bracket 6 is smalle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com