Cardboard box structure

A box structure, carton technology, used in rigid containers, containers, packaging and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following will clearly illustrate the spirit of the present invention with the accompanying drawings and detailed descriptions. After those skilled in the art understand the preferred embodiments of the present invention, they can be changed and modified by the technology taught by the present invention without departing from the present invention. The spirit and scope of the invention.

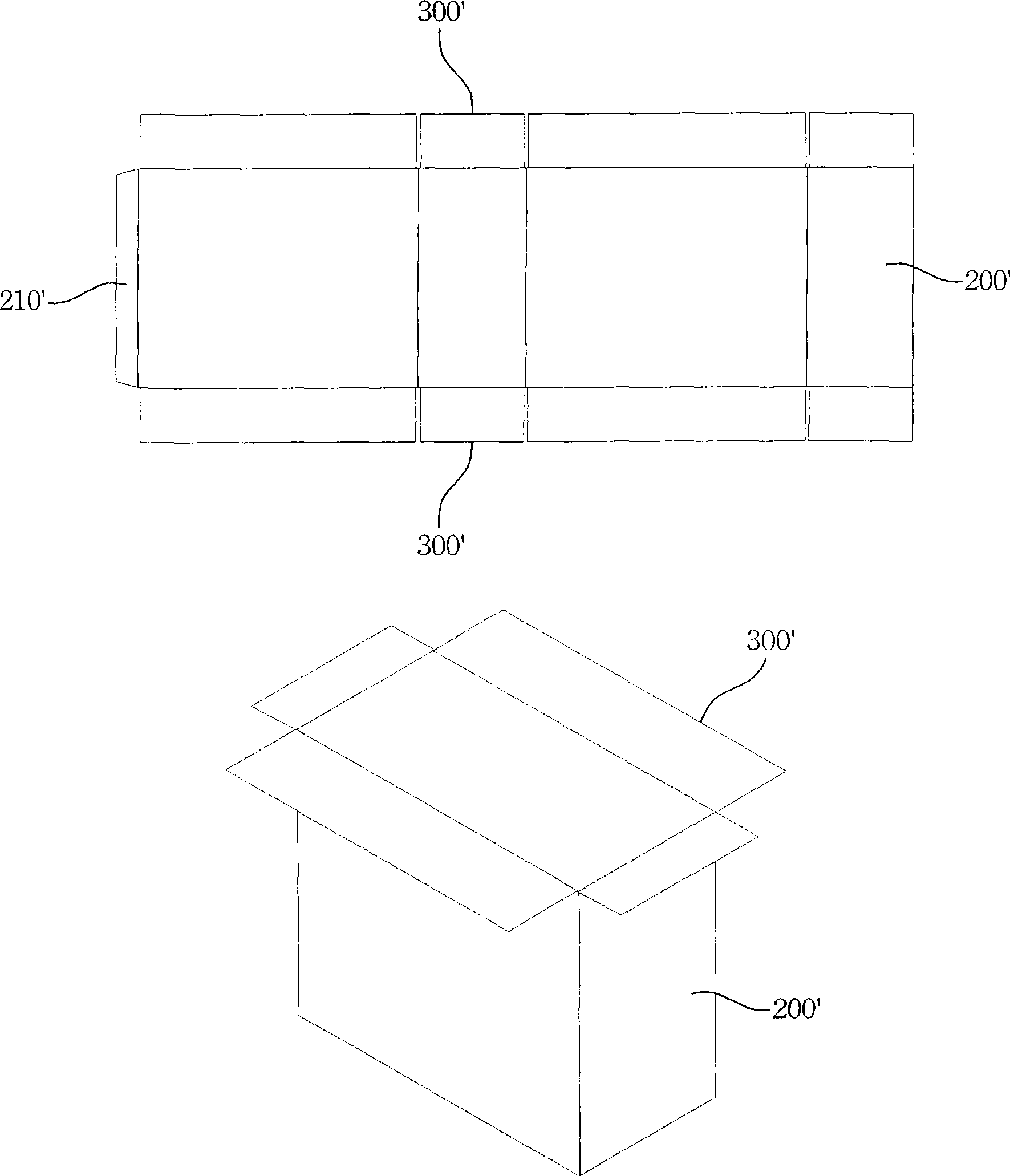

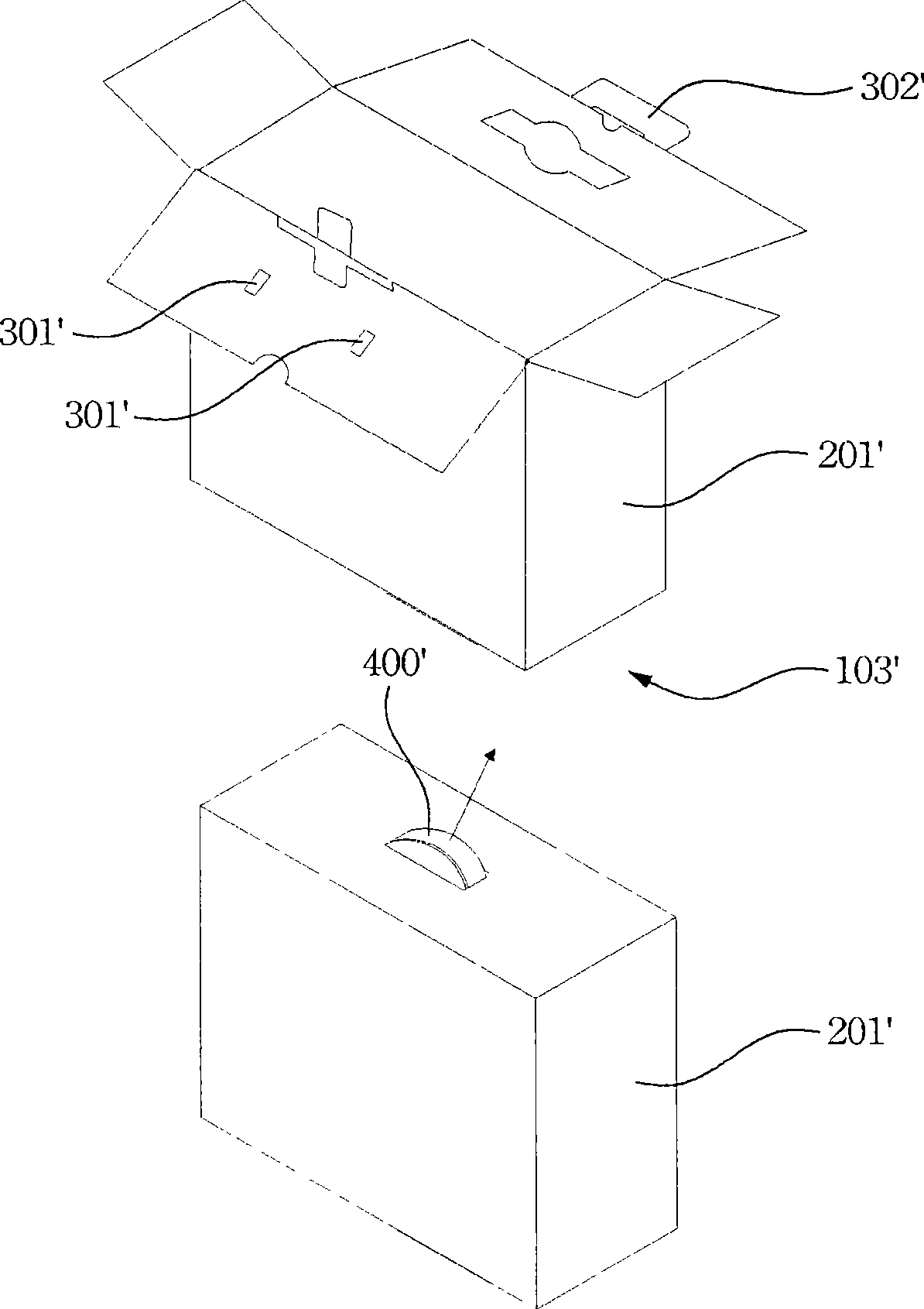

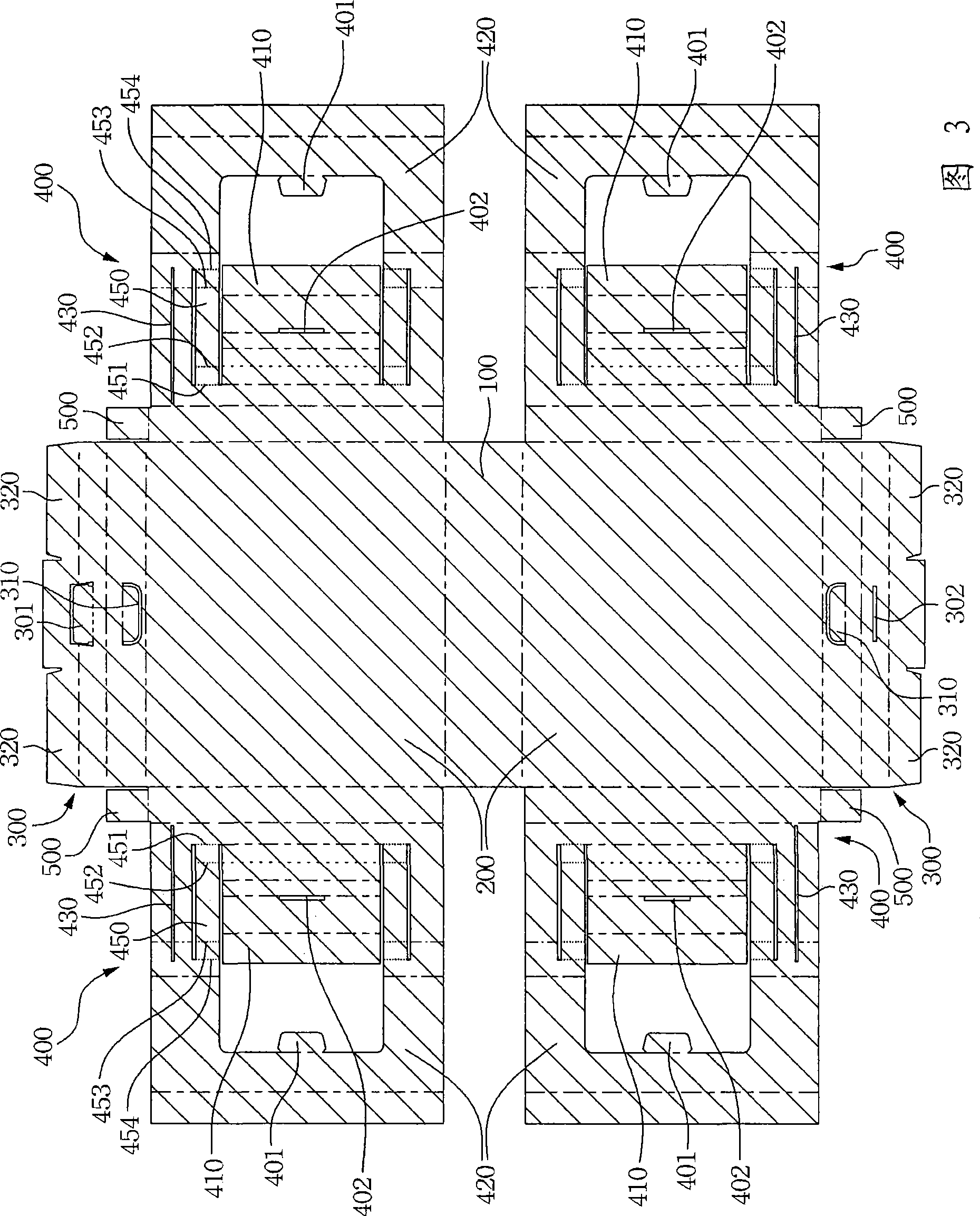

[0040] Fig. 3 shows the unfolded view of the sheet material of the carton structure of the present invention, the line segment shown in the figure is the mountain line folding (the sheet material on both sides of this line segment is folded toward the depth direction of the drawing, so that this line segment Protrusion), the ------ line segment shown in the figure is valley line folding (fold the sheet material on both sides of this line segment toward the floating direction of the drawing to make this line segment concave), as shown in the figure. ...The line segment can be folded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com