Silencer for automobile

A technology for mufflers and vehicles, applied in mufflers, machines/engines, mechanical equipment, etc., can solve the problems of reducing the muffler effect and increasing the exhaust back pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

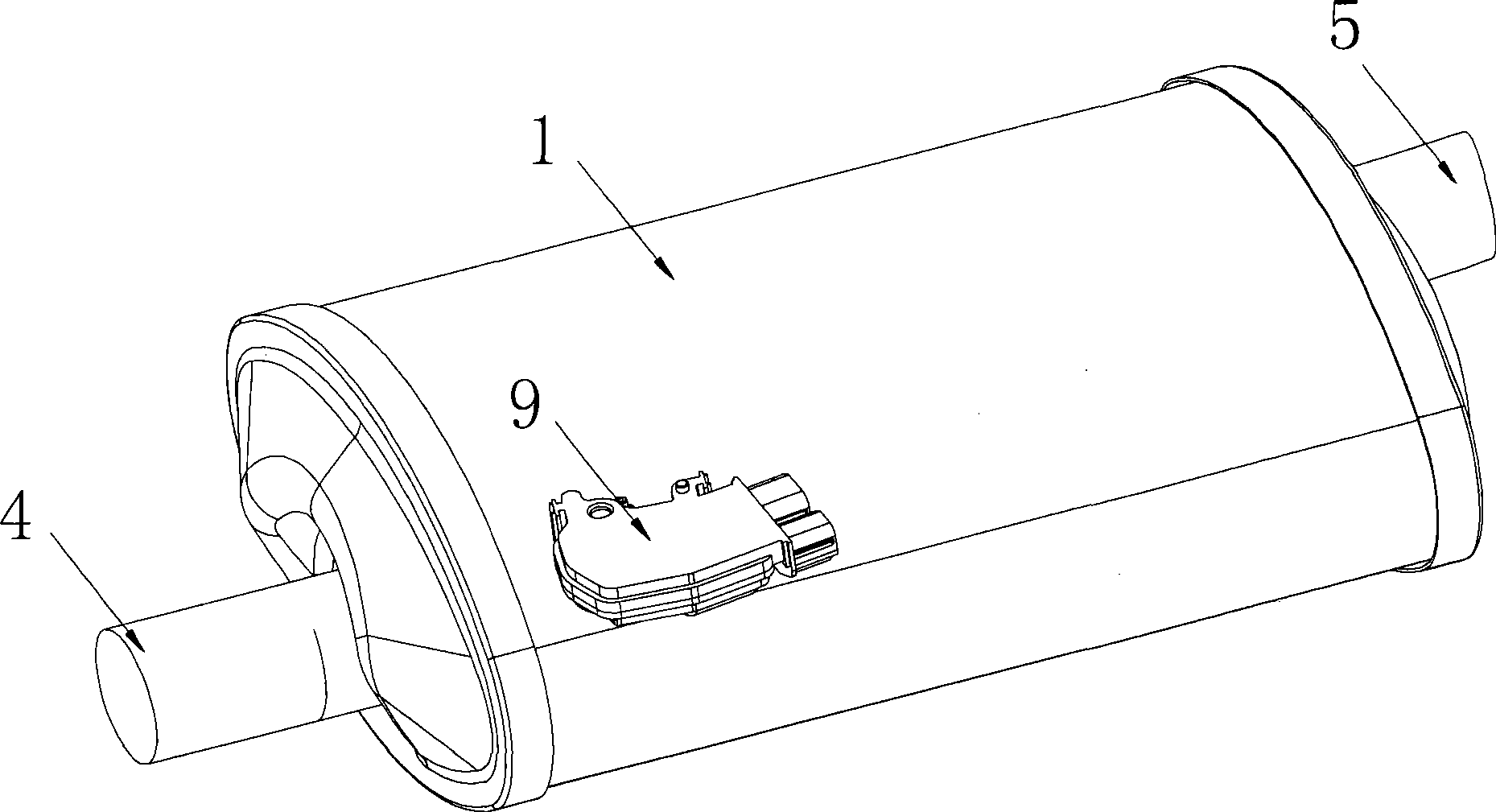

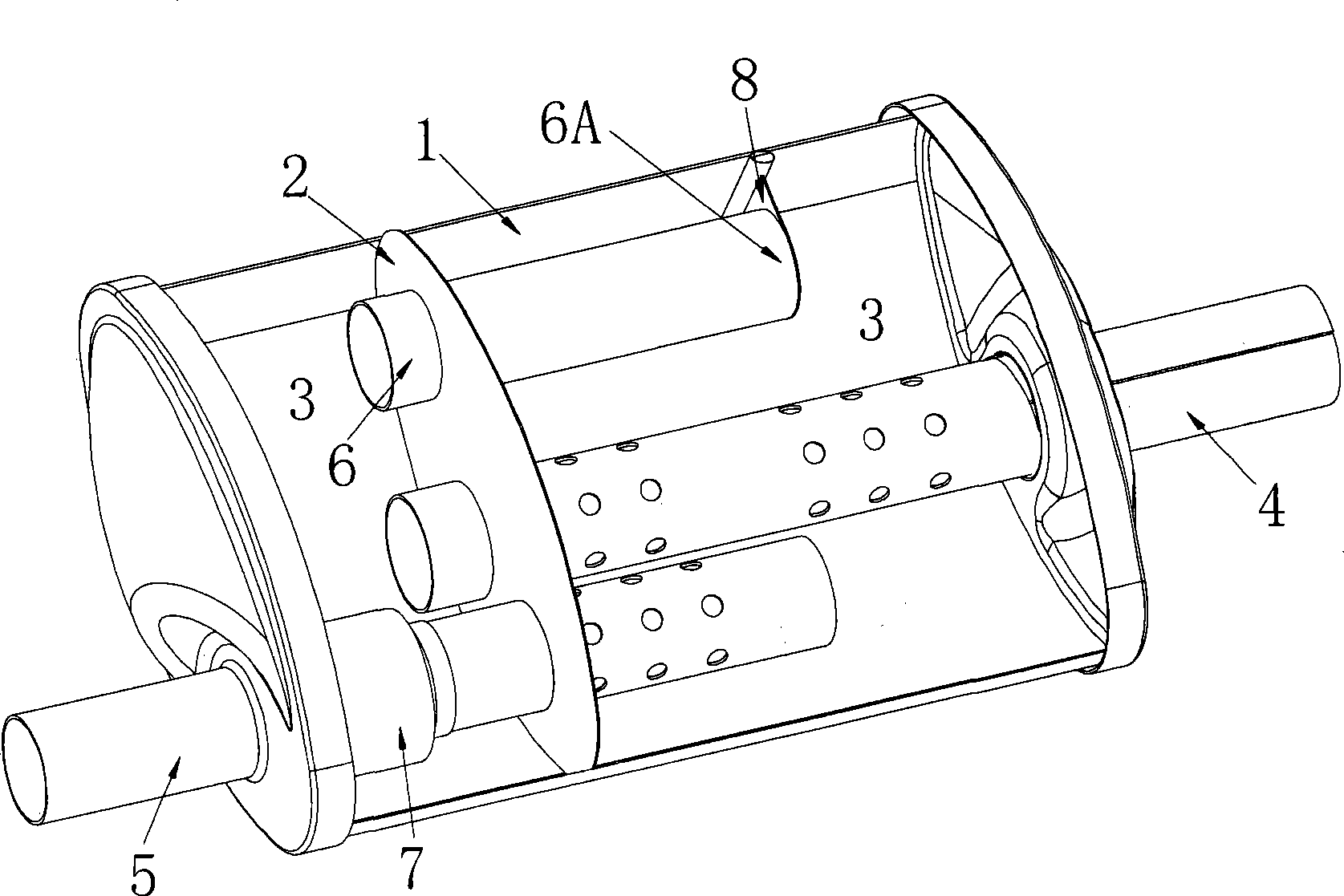

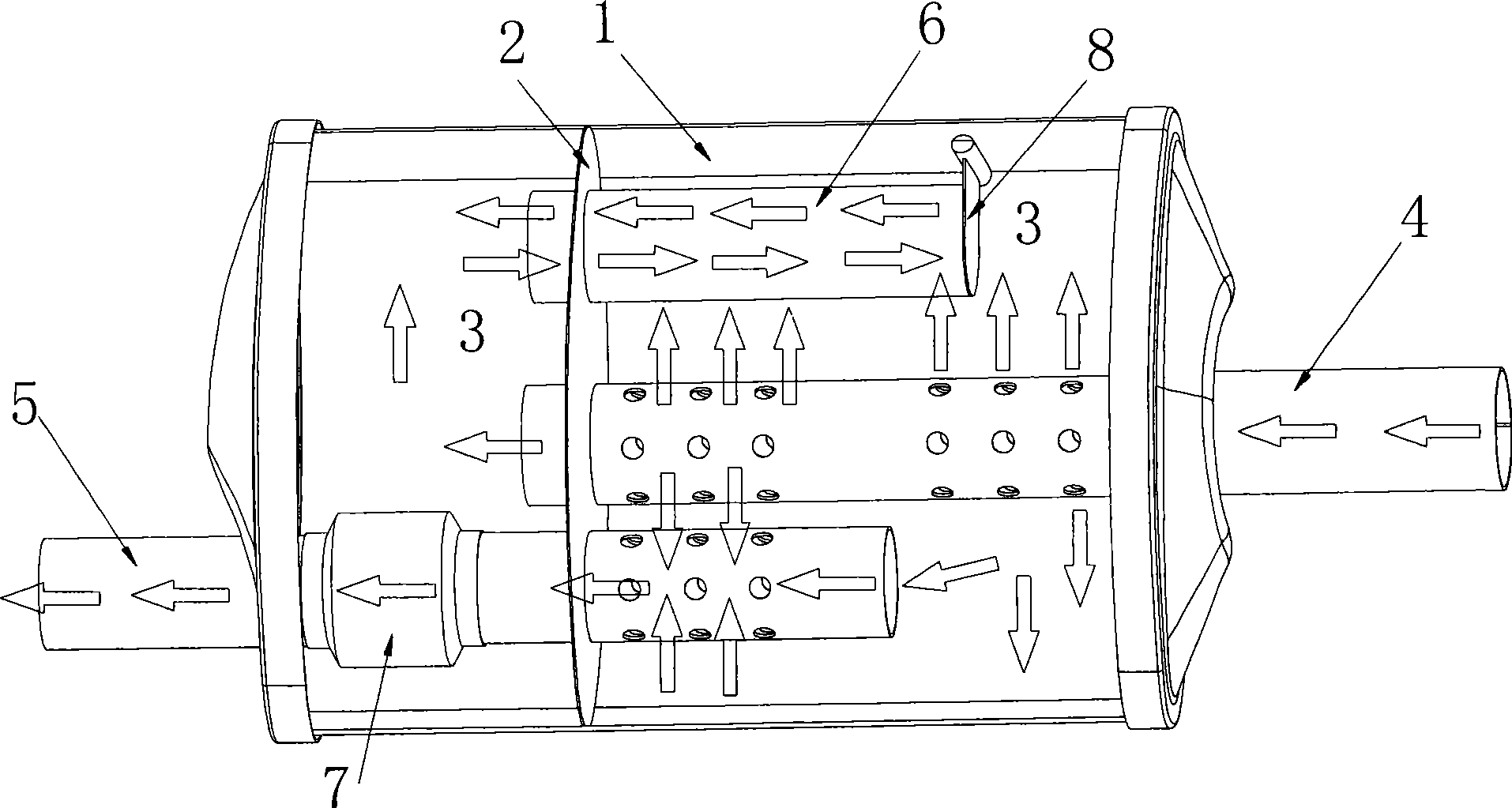

[0017] Such as figure 1 As shown, a vehicle muffler provided by the present invention includes a housing 1, an air intake pipe 4 and an air outlet pipe 5; wherein, the vehicle muffler also includes at least one partition plate 2, a resonance tube 6, a valve 8 and a valve control device 9; the outer edge of the at least one partition 2 is airtightly connected with the inner wall of the housing 1, and divides the interior of the housing 1 into at least two chambers 3 that are not communicated with each other; the The air inlet pipe 4 is inserted from one end of the housing 1, and passes through at least one chamber 3, and at least extends to the next chamber 3; the air outlet pipe 5 is inserted from the other end of the housing 1, and passes through at least one chamber 3, at least Extend to the next chamber 3; the inlet pipe 4 port located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com