FFS type TFT-LCD array substrate structure and manufacturing method thereof

A technology of array substrate structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, photoengraving process of pattern surface, instruments, etc., and can solve problems such as yield reduction, gate line-transparent electrode short circuit, quality problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

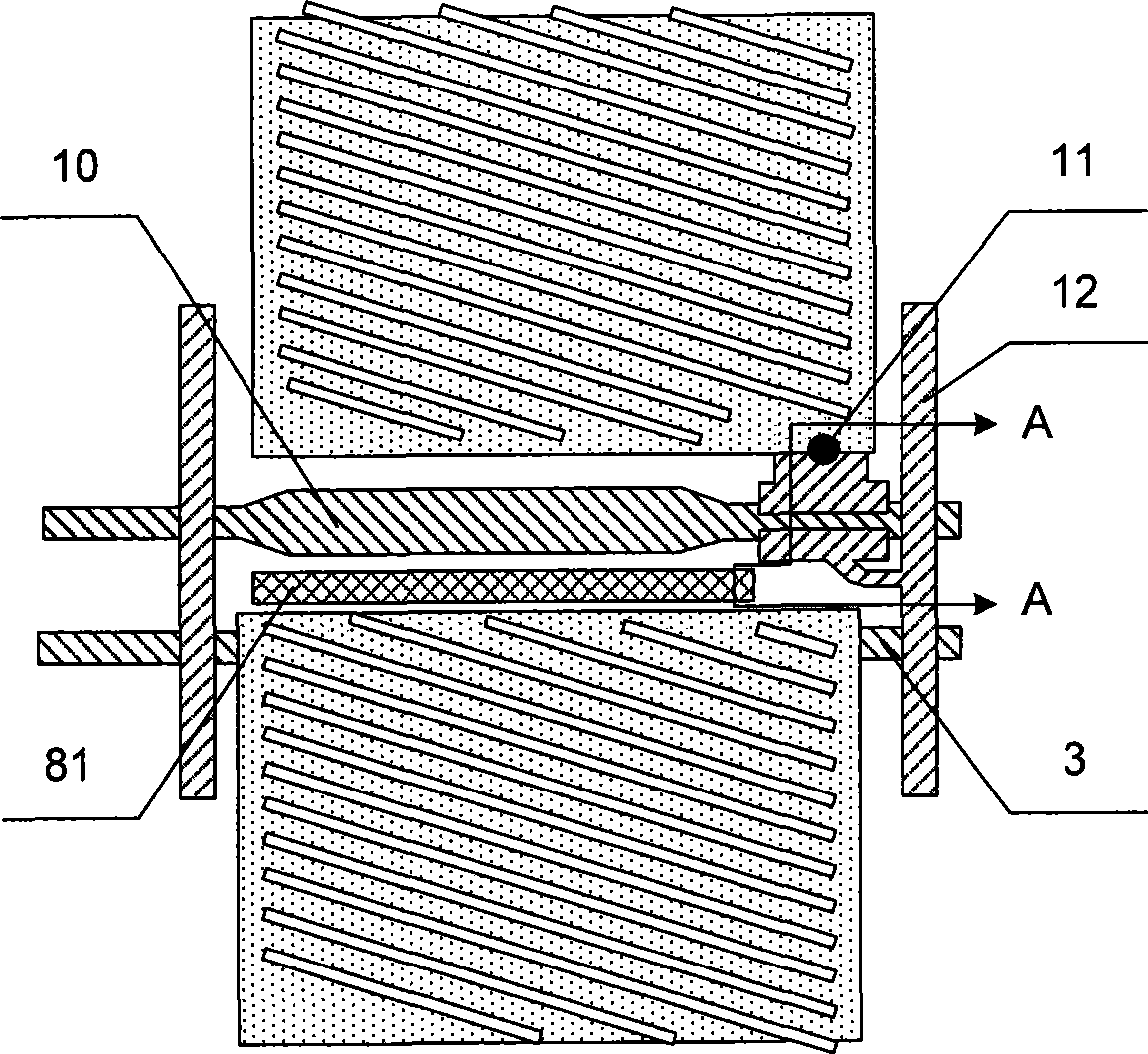

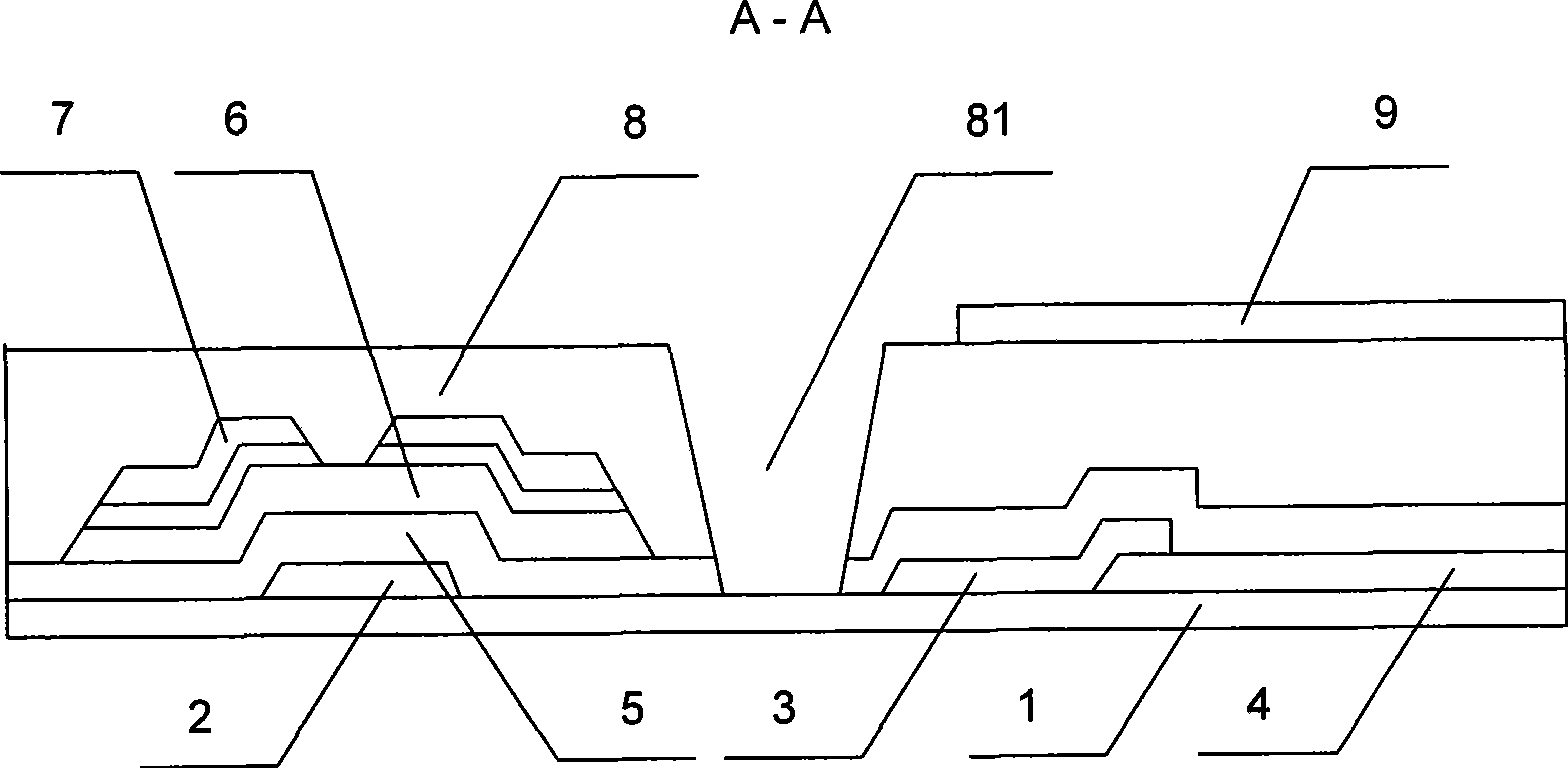

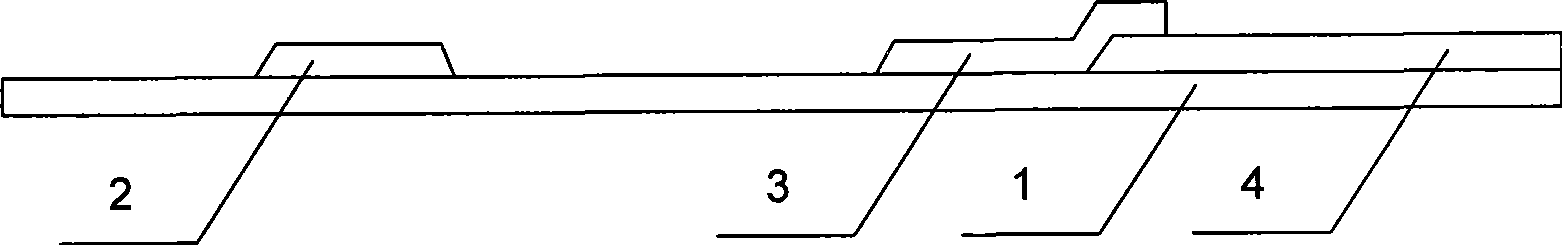

[0037] figure 1 It is a schematic diagram of the structure of the FFS type TFT-LCD array substrate of the present invention, figure 2 for figure 1 Middle A-A sectional view. like figure 1 , figure 2 As shown, the array substrate structure of the present invention includes a glass substrate 1, and gate electrodes 2, gate lines 10, common electrode lines 3 and transparent electrodes 4 are formed on the glass substrate, and the gate lines 10 and common electrode lines 3 are arranged in isolation. It is connected with the transparent electrode 4 to form a common electrode. The gate insulating layer 5 is formed on the glass substrate and covers the gate electrode 2, the gate line 10, the common electrode line 3 and the transparent electrode 4. The active layer 6 and the source-drain electrode layer 7 are sequentially formed on the On the glass substrate and above the gate electrode 2, the source-drain electrode layer 7 includes the source electrode, the drain electrode and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com