A hybrid primary optical component for optical concentrators

An optical component and hybrid technology, applied in the direction of optical components, optics, condenser mirrors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention described below are not intended to be exhaustive or to limit the invention to the precise forms disclosed in the following detailed description. Rather, these embodiments were chosen and described for the purpose of helping others skilled in the art to more easily evaluate and understand the principles and practice of the present invention.

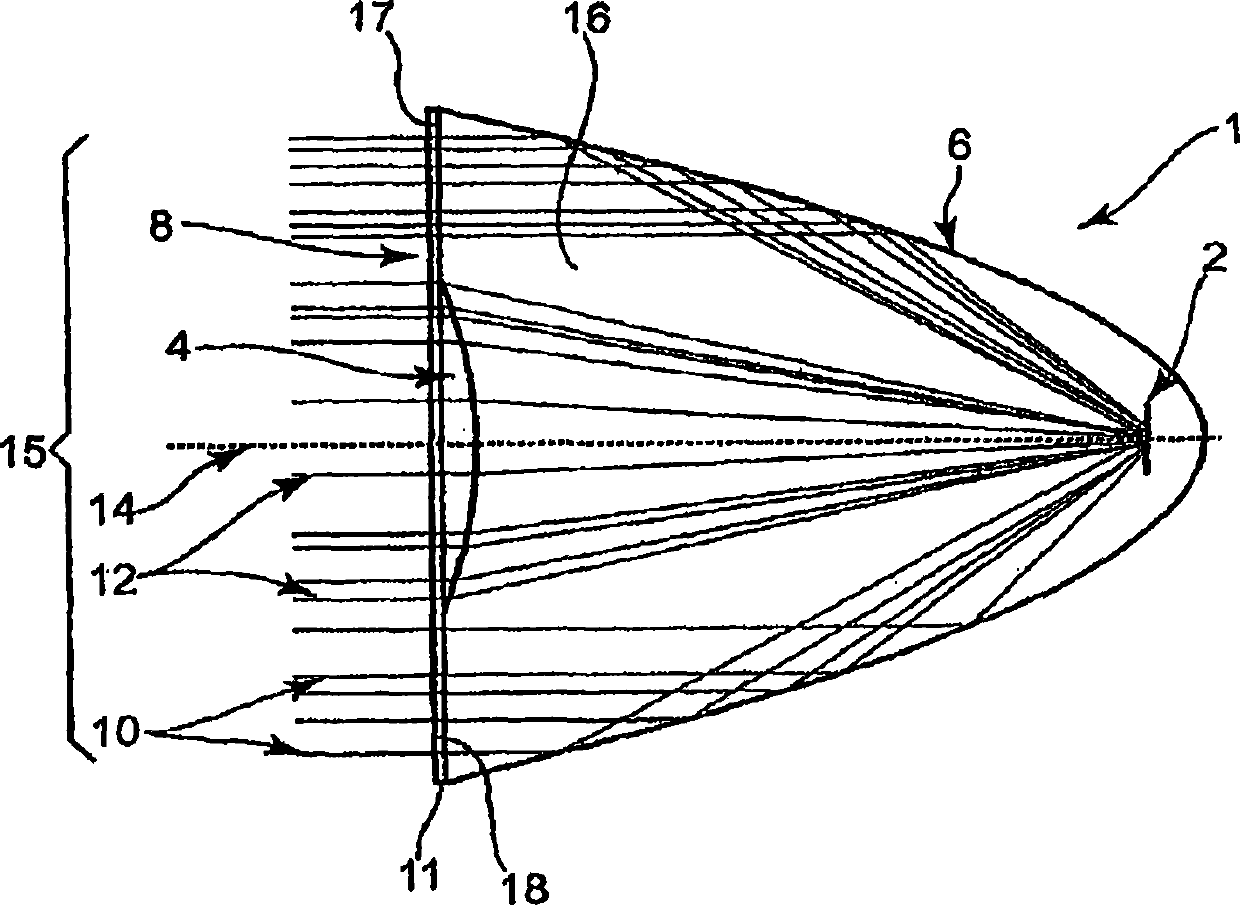

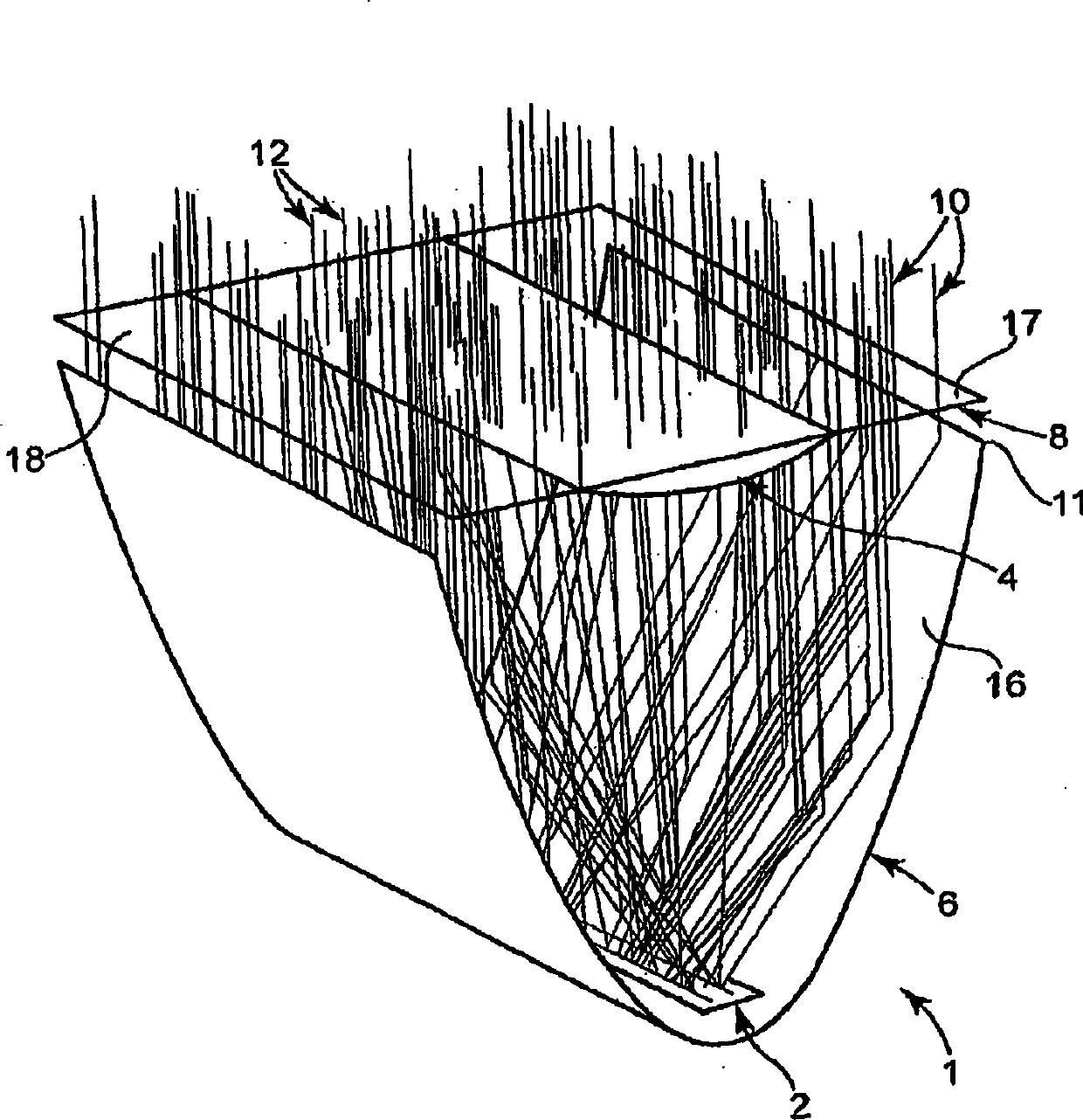

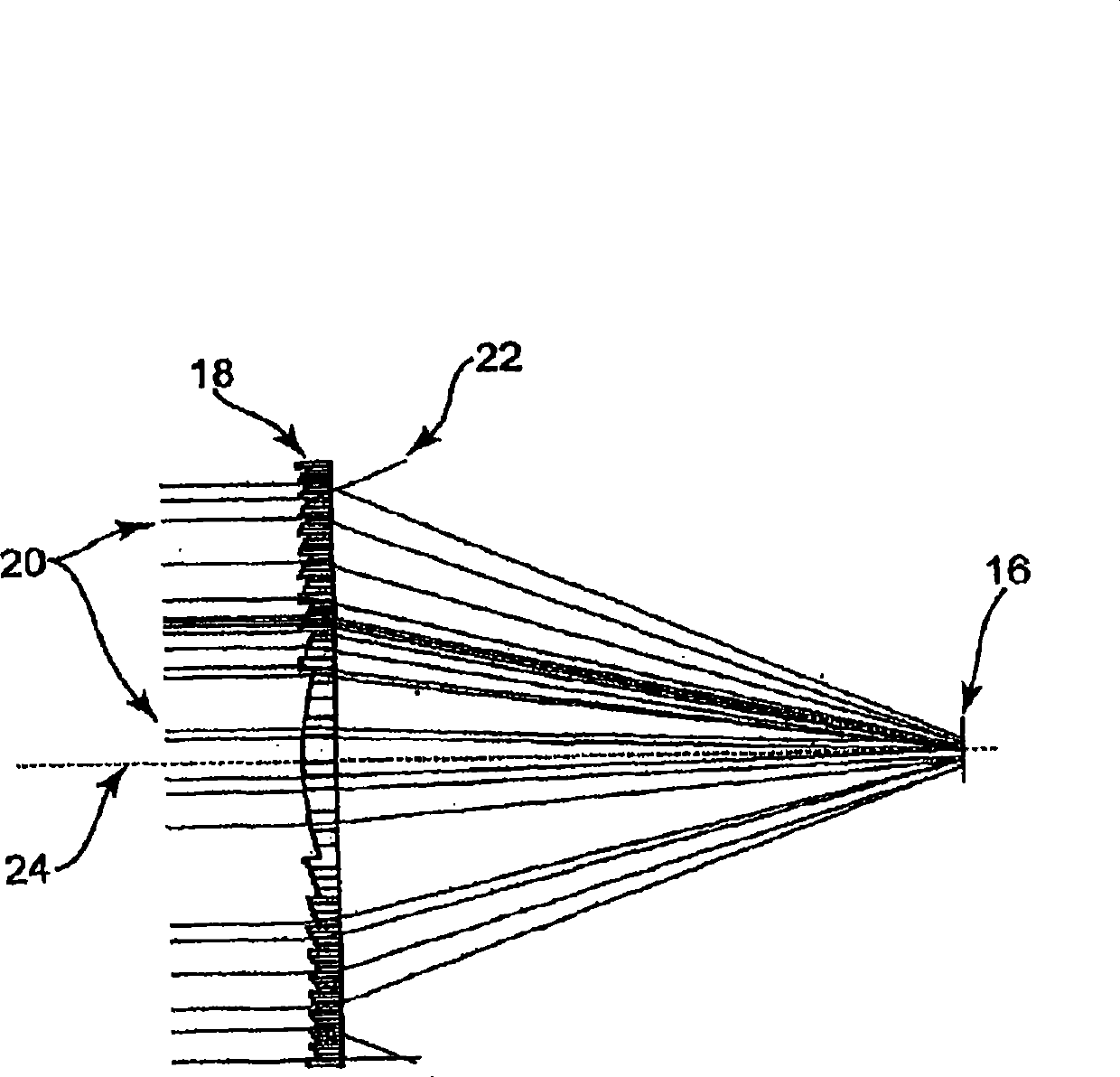

[0033] Figure 1a, Figure 1b and Figure 7 A preferred embodiment of the hybrid primary optic 1 of the invention is shown. For illustration purposes, the optical component 1 is in the form of a linear concentrator. The full aperture 15 of the component 1 spans the width (in the case of a line concentrator) or the diameter (in the case of a point concentrator) of the light receiving end 11 of the reflective element in the form of a bottom focusing dish 6 . This hybrid primary optic 1 includes a top cover 8 fitted onto a light receiving end 11 . The top cover 8 and tray 6 together provide a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com