Device for transporting grain used on feeding-wheel device

A technology of conveying device and feeding wheel, which is applied in application, agricultural machinery and implements, harvesters, etc. It can solve the problems of troublesome replacement and maintenance, easy aging, and many contact surfaces, so as to achieve less replacement and maintenance and less failure rate , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

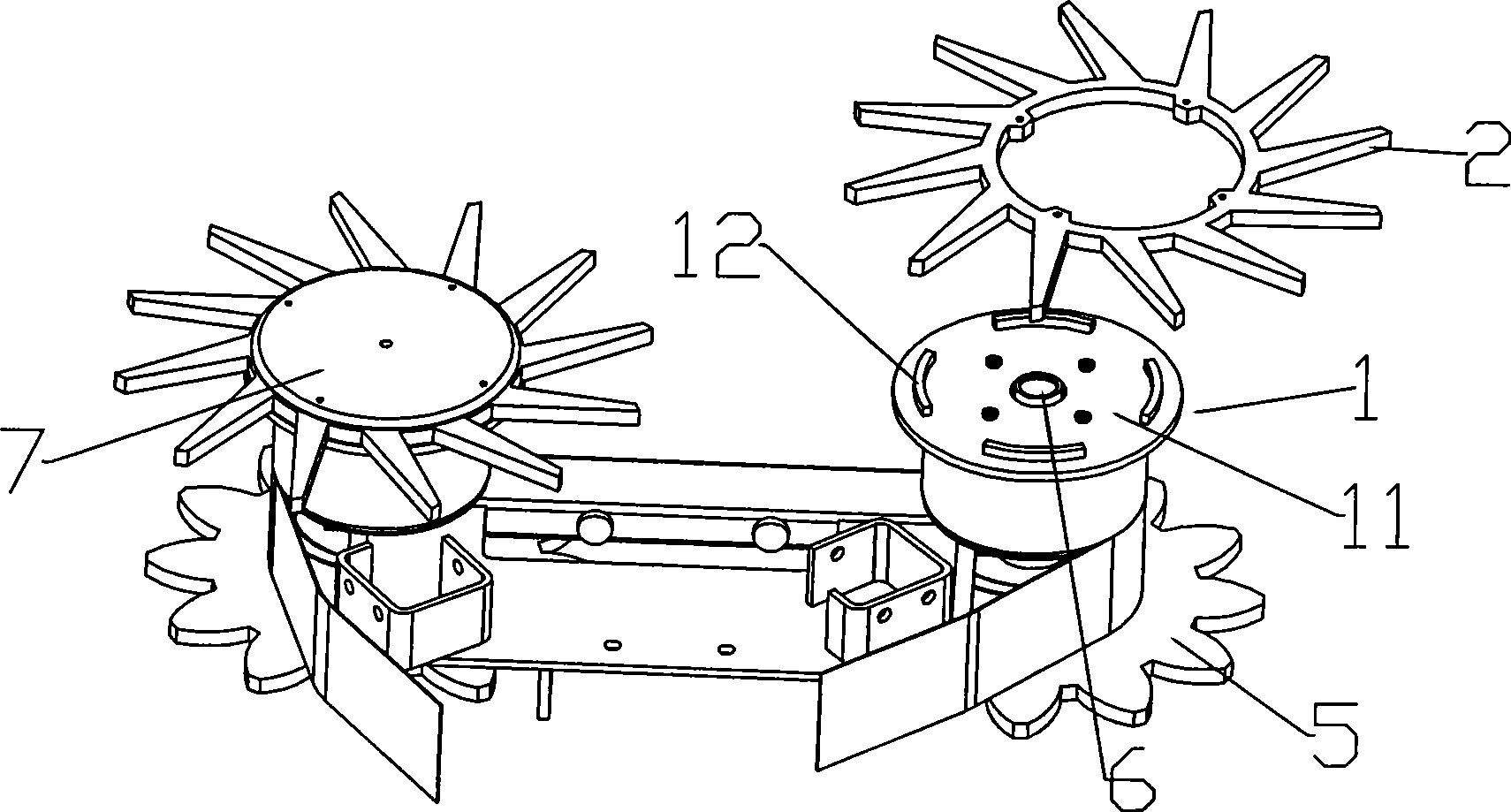

[0018] Below in conjunction with accompanying drawing the present invention is used for the ear conveying device on the feeding wheel device to be further described:

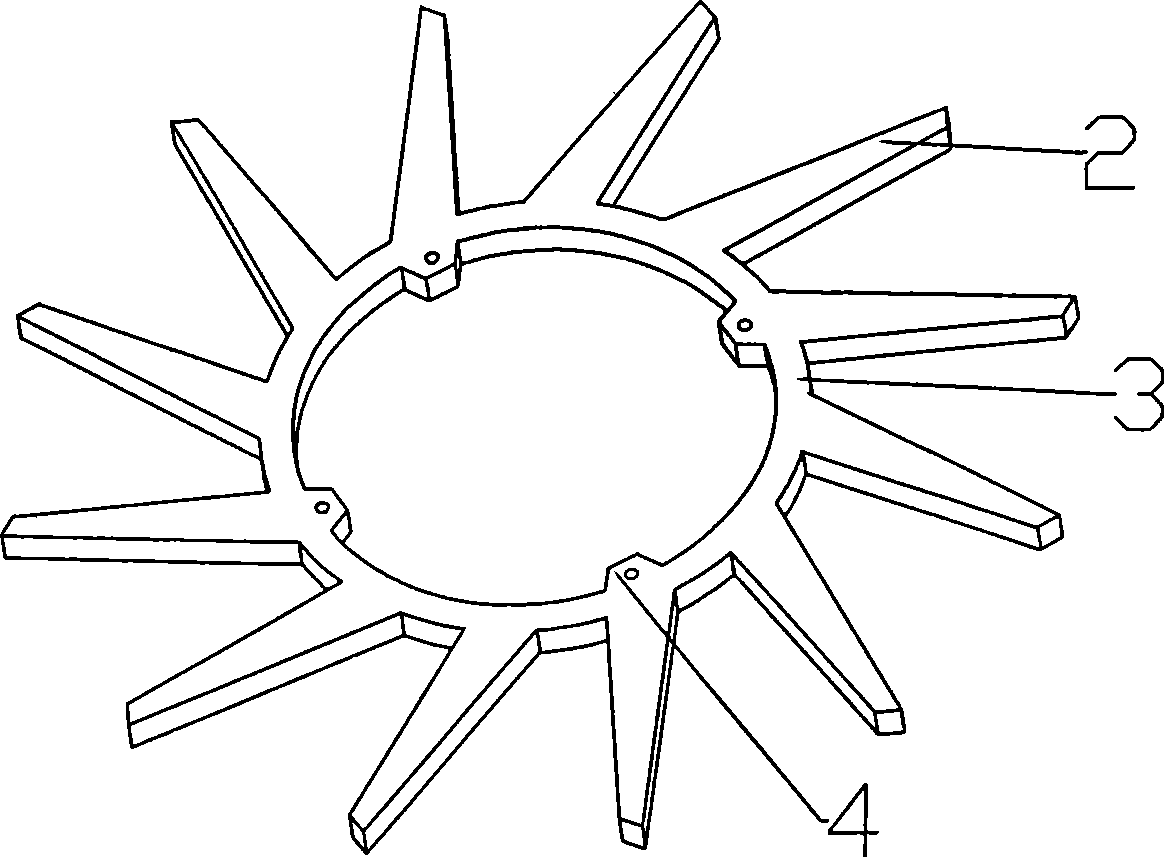

[0019] Such as figure 1 , figure 2 As shown, the present invention is used for the ear conveying device on the feeding wheel device, including a belt guide wheel 1 coaxially installed on the feeding wheel shaft 6 with the toothed feeding wheel 5, a conveying protruding claw 2, and a belt guide wheel 1 Coaxial disc 11 is provided on the top, and conveying protruding claw 2 is fixed on the disc 11 of belt guide wheel 1, and each conveying protruding claw 2 takes the rotating shaft center of belt guide wheel 1 as the center of symmetry and is distributed in a divergent shape at equal intervals. Each conveying claw 2 can also be fixed on the disc 11 of the belt guide wheel 1 by the belt 3, and each conveying claw 2 and the belt 3 are integrally made of the same piece of material. The belt 3 is annular, and each c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com