Method and device for forming internal gear

An internal gear and tooth profile technology, applied in the field of internal gear forming and forming devices, can solve the problems of poor strength and durability of parts, unqualified, and high degree of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

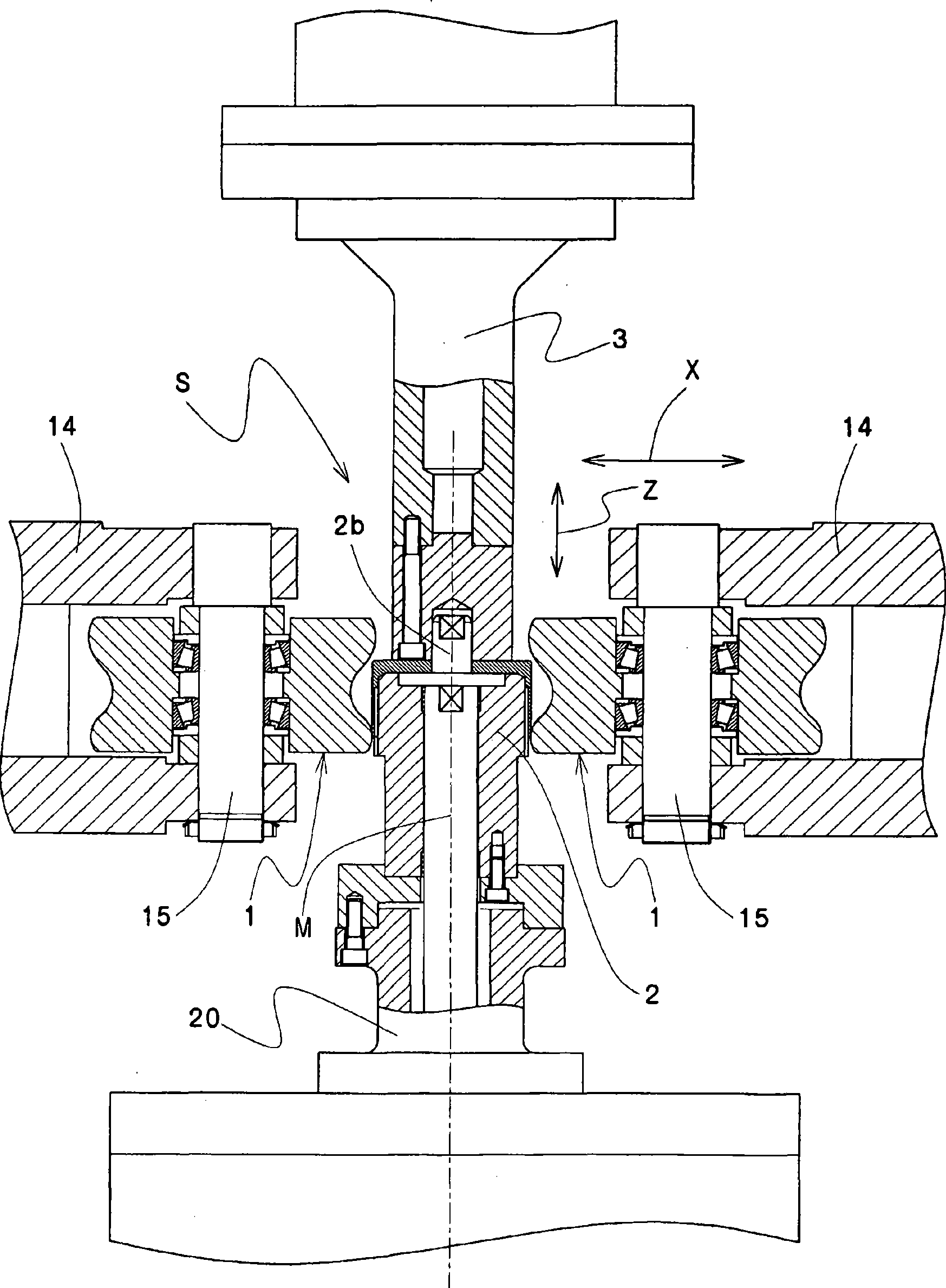

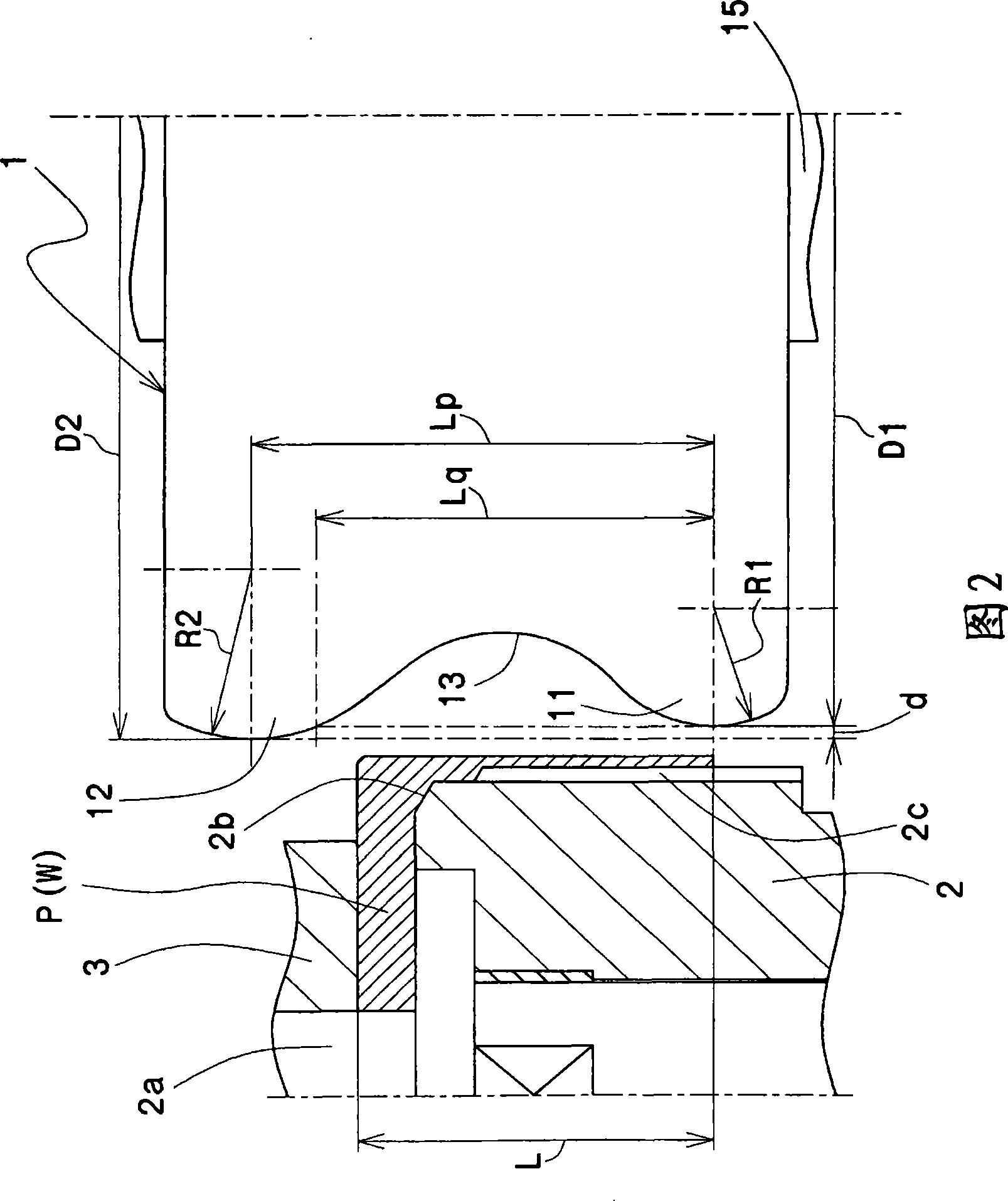

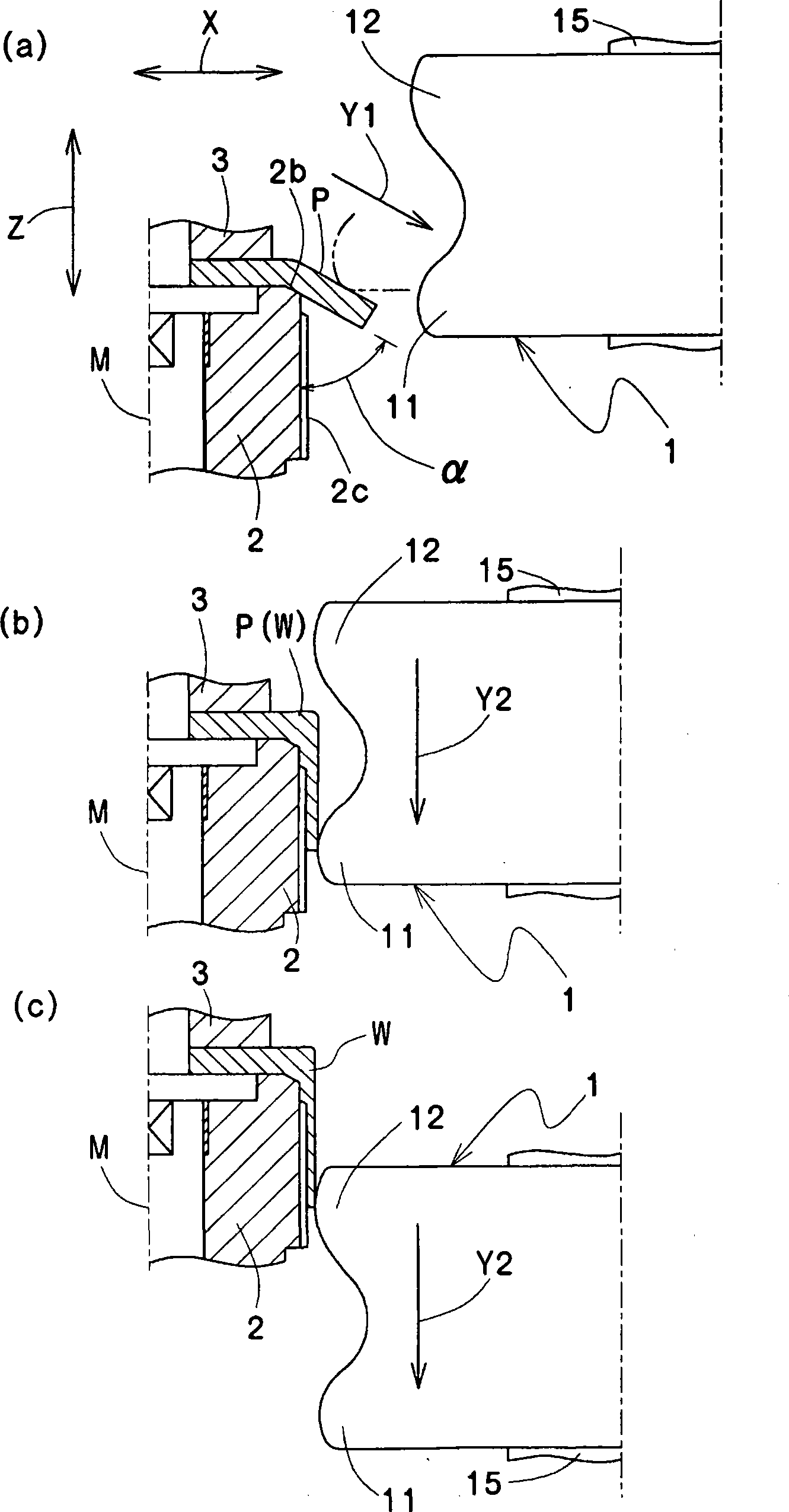

[0021] Figure 1 ~ Figure 3 An example of the forming method and forming apparatus of the internal gear of the present invention is shown.

[0022] This internal gear forming device installs a disc-shaped blank P on a mandrel 2 having a tooth profile 2c on the peripheral surface, and uses circular arc portions R1, R2, and Compared with the outer diameter D1 of the arc portion R1 that first contacts with the disc-shaped blank P, the drawing roll 1 whose outer diameter D2 of the arc portion R2 in contact with the latter is increased, so that the drawing roll 1 is in contact with the mandrel. 2 moves in a direction parallel to the axis center to form a cylindrical internal gear W.

[0023]This internal gear shaping device S consists of a spindle 2 having a tooth shape 2c on the outer peripheral surface provided on the front end of a rotating main shaft 20, a pressing member 3 provided opposite to the spindle 2, and a pair of shafts mounted on the spindle. The shaft 2 is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com