Method for controlling coating alloying homogeneity

An alloying and uniform technology, applied in coatings, manufacturing tools, hot dipping processes, etc., can solve the problems of uneven soaking temperature and cooling rate of alloying, insufficient consideration of problems, and no countermeasures to improve, etc. Achieve the effect of improving stability, ensuring uniformity, and uniform coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0050] The plan adopted is:

[0051] (1) Optimize the process parameters of the air knife to obtain a coating with a more uniform thickness;

[0052] (2) The touch roll device is used to stabilize the strip.

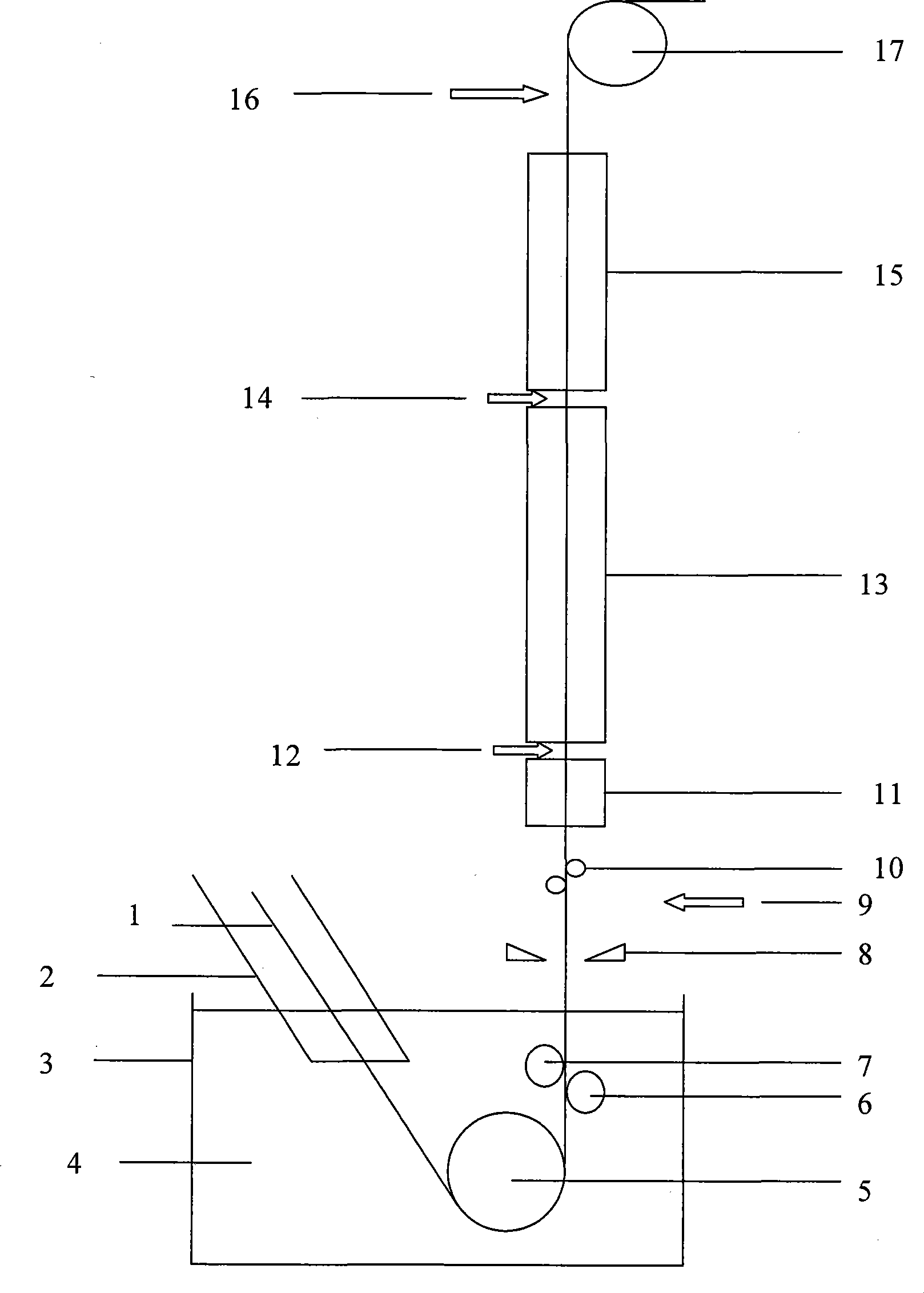

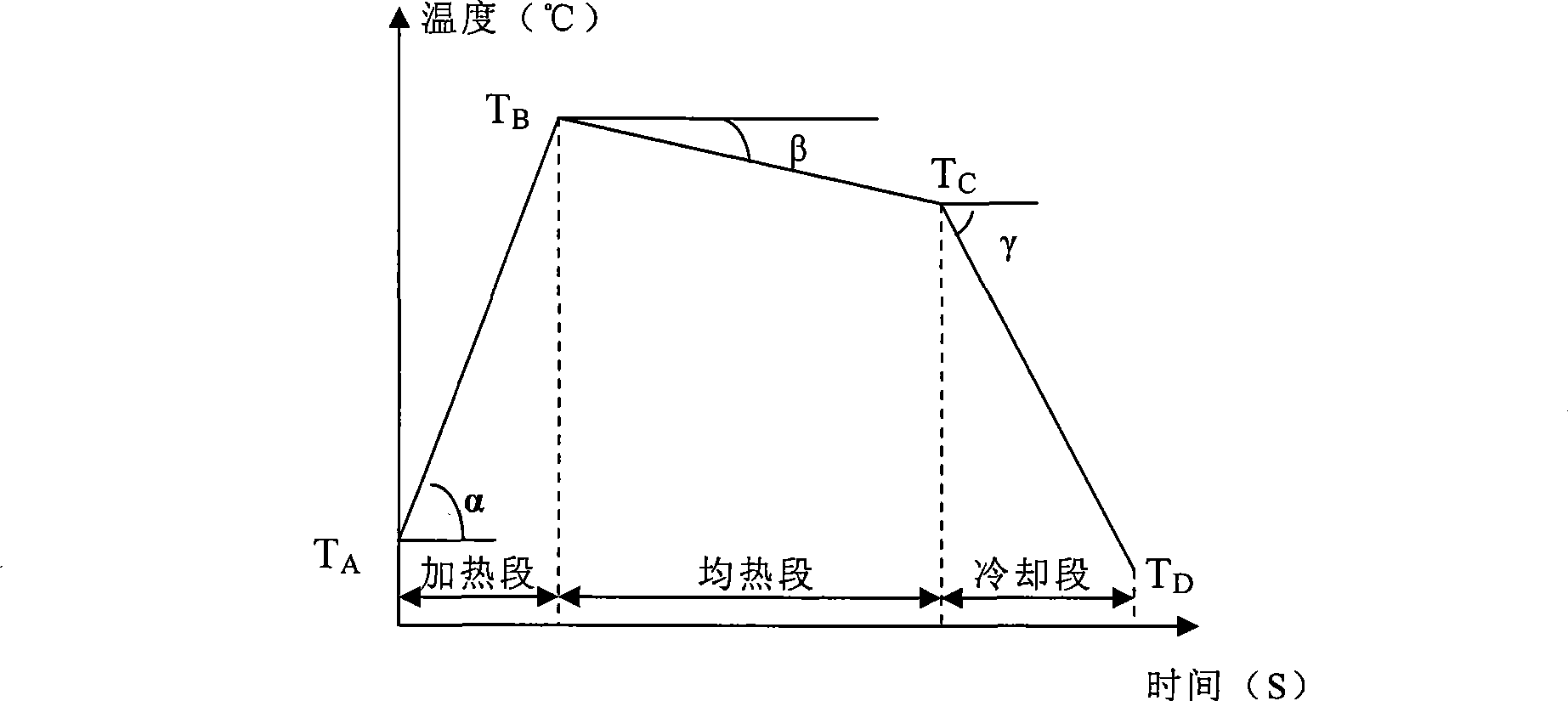

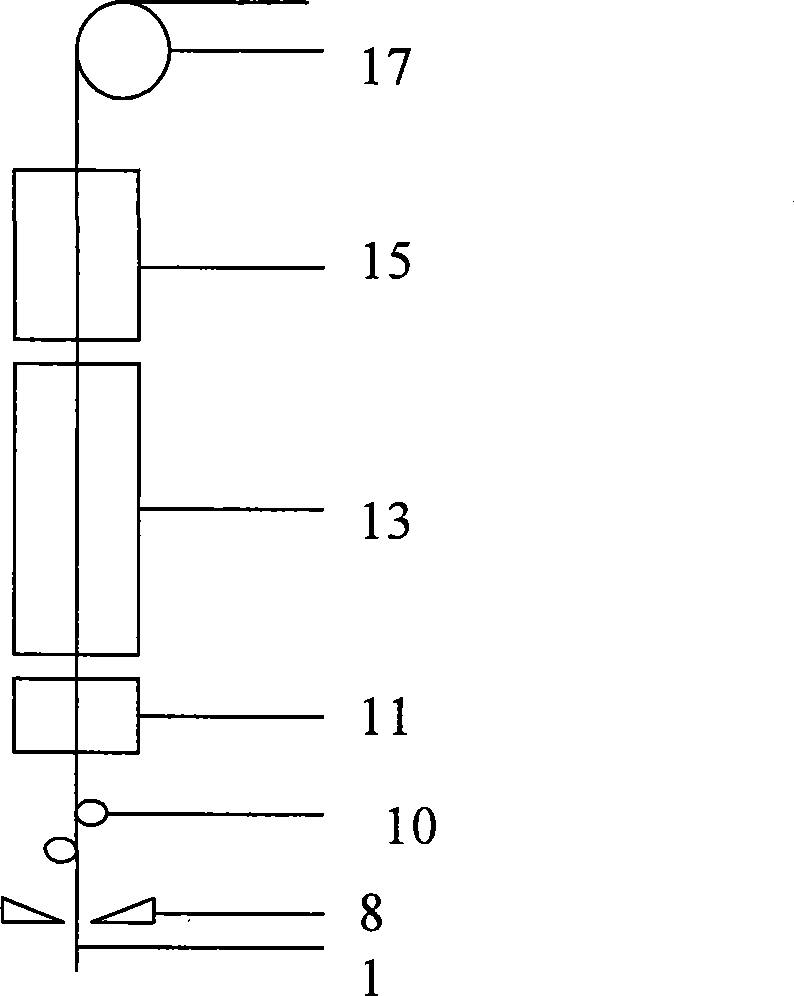

[0053] A hot-dip galvanizing unit optimizes the process parameters of the air knife, and adopts image 3 In the contact roll device shown, the strip steel 1 is purged by the air knife 8 and stabilized by the touch roll 10, then enters the heating section 11, the soaking section 13 and the cooling section 15 of the alloying furnace for annealing treatment of the coating alloy coating. Table 1 is the combination process parameters of air knife pressure, strip steel speed and air knife distance. Through the combination of parameters in Table 1, and the use of air knife edge baffles and touch rolls, alloyed hot-dip galvanized products with very good coating uniformity can be produced.

example 2

[0055] The plan adopted is:

[0056] (1) Electromagnetic stabilization device is used to stabilize the strip steel;

[0057] (2) In the cooling section of the alloying furnace, adopt Figure 7 Shown is the jet cooling device to obtain uniform cooling for plating alloying.

[0058] Figure 4 It is a schematic diagram of the implementation of stabilizing strip steel with an electromagnetic stabilizing device. After the strip steel 1 is purged by the air knife 8 and stabilized by the electromagnetic stabilizing device 33, it enters the heating section 11, the soaking section 13 and the cooling section 15 of the alloying furnace for coating alloying Coating annealing treatment. At the cooling section 15 of the alloying furnace, the Figure 7 In the air jet cooling device shown, the nozzles on the upper and lower surfaces of the strip steel 1 are divided into five sections, and the gas injection speed of each section is adjustable. Horizontal uniform band temperature. In this...

example 3

[0060] The plan adopted is:

[0061] (1) Use contact rolls to stabilize the strip;

[0062] (2) The air knife edge baffle device is used to obtain a more uniform thickness of the coating;

[0063] (3) The strip edge burner is adopted to make the strip enter the alloying heating furnace at a more uniform transverse temperature;

[0064] (4) In the soaking section, use the device shown in Figure 8 with the heat preservation furnace wall that can be moved horizontally to adjust the thermal insulation performance or heat dissipation performance of the soaking section, so as to achieve uniform soaking of the coating alloying.

[0065] Figure 5 It is a schematic diagram of the touch roll and the edge burner for industrial application. After the strip steel 1 is stabilized by the touch roll 10, before entering the heating section 11 of the alloying furnace, the edge burner 43 is used for flame heating to compensate the heat of the edge of the strip steel. loss. A total of 8 burner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com