Closestool for directly flushing with tap water

A tap water and toilet technology, applied in flushing equipment with water tanks, water supply devices, buildings, etc., can solve the problems of wasting materials, wasting water, occupying space, etc., and achieving the effect of saving materials and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

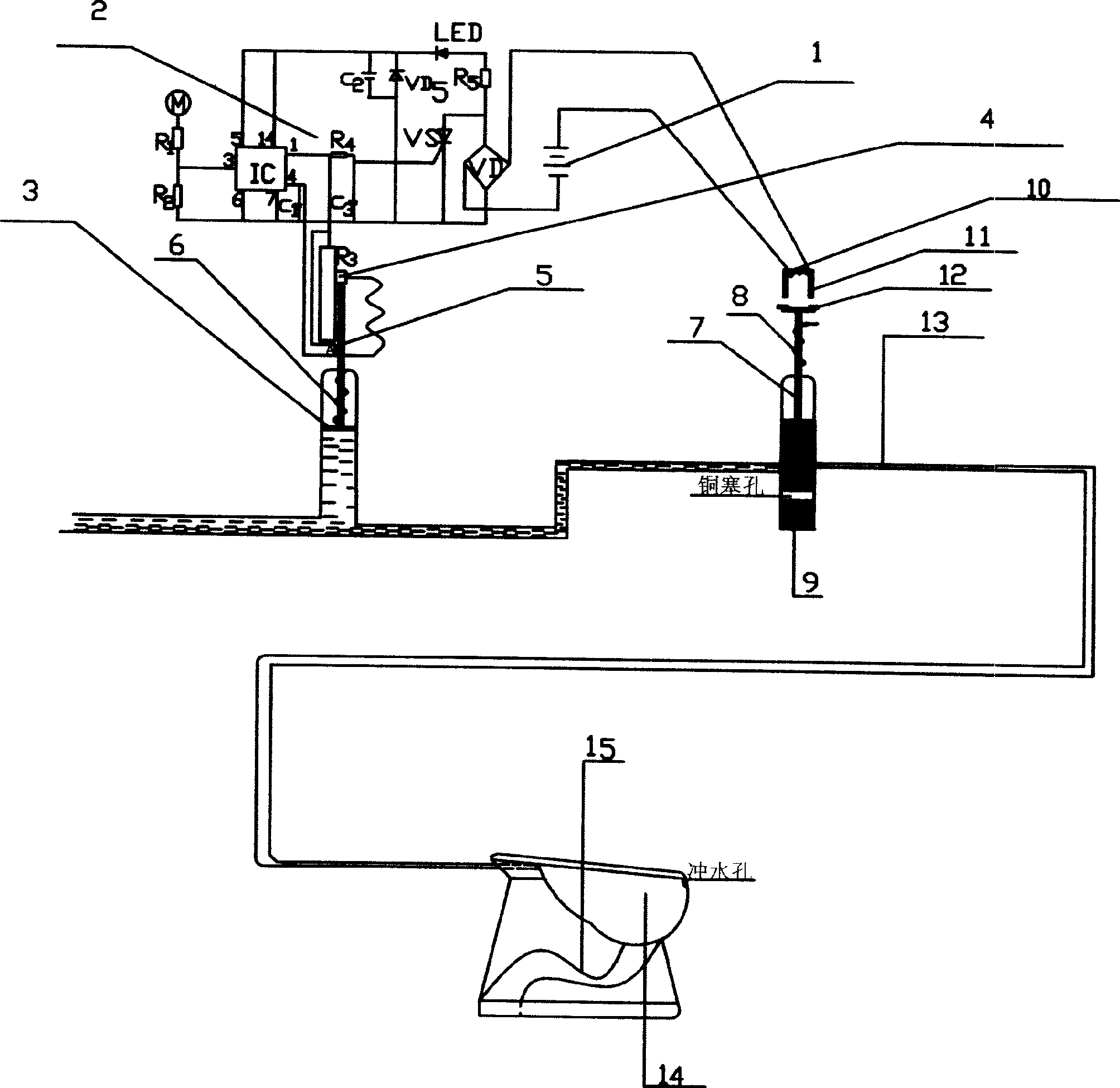

[0008] The invention consists of the following parts: power supply (1), touch delay switch (2), rubber sheet (3), contact head (4), plastic rod (5), spring (6), plastic rod (7), spring (8), copper plug (9), coil (10), iron core (11), the control system of the control tap water switch that soft iron (12) forms, water pipe (13), toilet seat (14), has trap The flushing system that downpipe (15) forms.

[0009] In the figure, the rubber sheet (3) is connected to the plastic rod (5) covered with the spring (6), and the plastic rod (5) is connected to the contact head (4). Resistance R3, wire head A and contact head (4) form sliding resistance, according to the negative pressure of running water, no pressure and the pressure size when there is pressure control the delay length of touch delay switch (2). A closed circuit composed of a power supply (1), a touch delay switch (2) and a coil (10) controls the opening and closing of an electromagnet composed of an iron core (11) and a so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com