Process for processing PVC waste water using automatic brush type filter and ultrafilter

A technology of polyvinyl chloride and automatic brushing, which is applied in the direction of fixed filter elements, ultrafiltration, filtration separation, etc., and can solve problems such as ultrafiltration clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

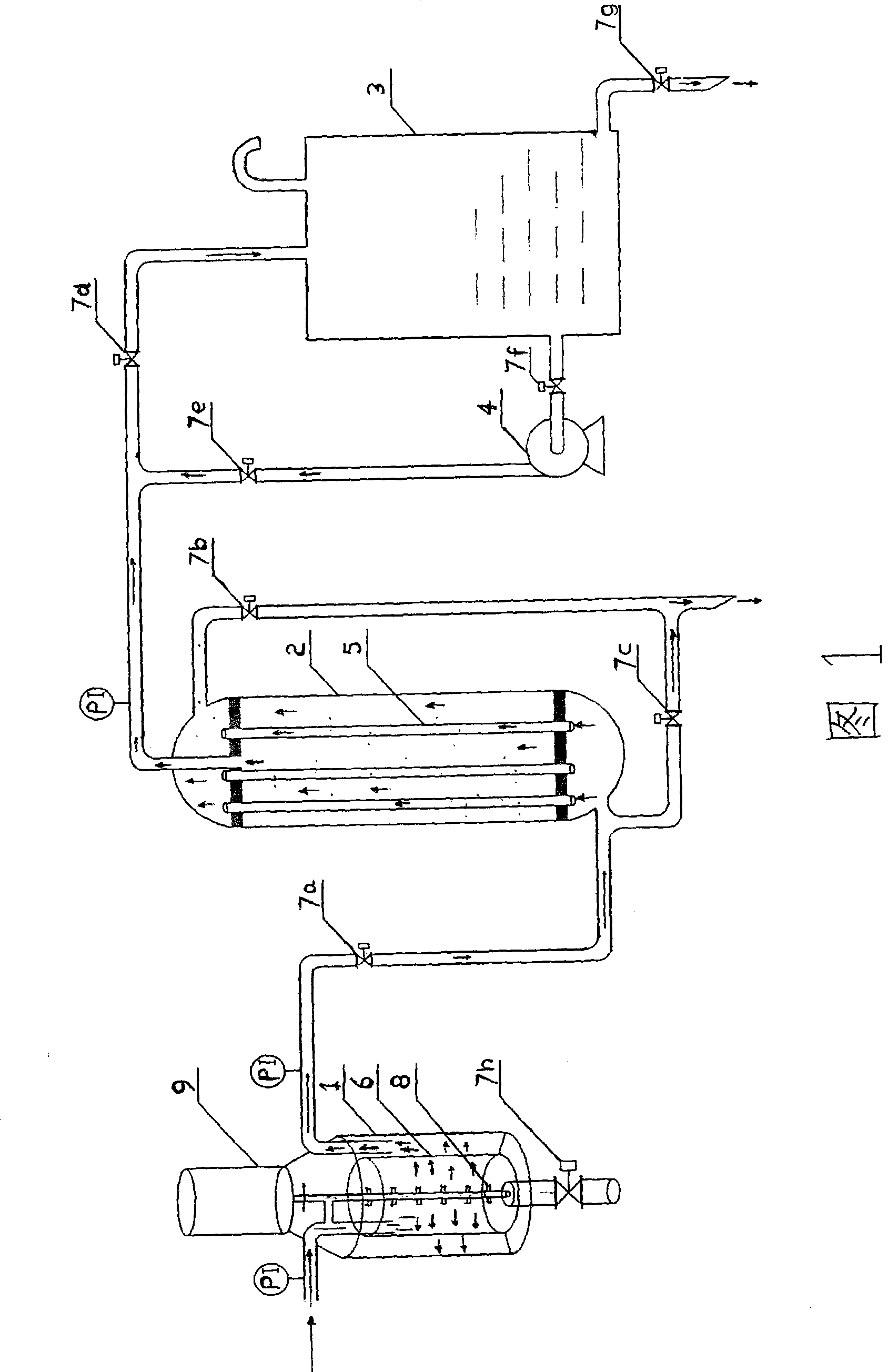

Embodiment 1

[0027] The polyvinyl chloride wastewater including domestic wastewater is adjusted and neutralized, oxidized and precipitated, and after biochemical treatment, 22g of ferric chloride flocculant is added, pumped into the filter cartridge of the automatic brush filter [1], and passed through the stainless steel mesh [1]. 6] Filtration to remove solid particles with a particle size greater than 0.13mm, and enter the hollow fiber membrane [5] tube of the ultrafilter [2] through the valve [7a], and the filtered water from the side of the hollow fiber membrane tube is collected in the outlet pipe, Through the valve [7d] into the water storage tank [3], the water quality after ultrafiltration is pH 7.9, turbidity 0mg / l, total dissolved solids 5200mg / l, conductivity 4500μS, chemical oxygen consumption 75mg / lO 2 , Ultra-filtered water is used for concentration and desalination, and finally reaches zero discharge. In order to ensure that the ultrafilter [2] can operate for long-term tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com