Rotary foundation support arm crank bidirectional balancing double-well pumping unit

A technology of rotating base and pumping unit, which is applied in the direction of mechanical equipment, wellbore/well components, production fluid, etc. It can solve the problems of the length of the beam and the limitation of the workover operation range, so as to reduce the weight of the whole machine and shorten the beam The effect of length and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

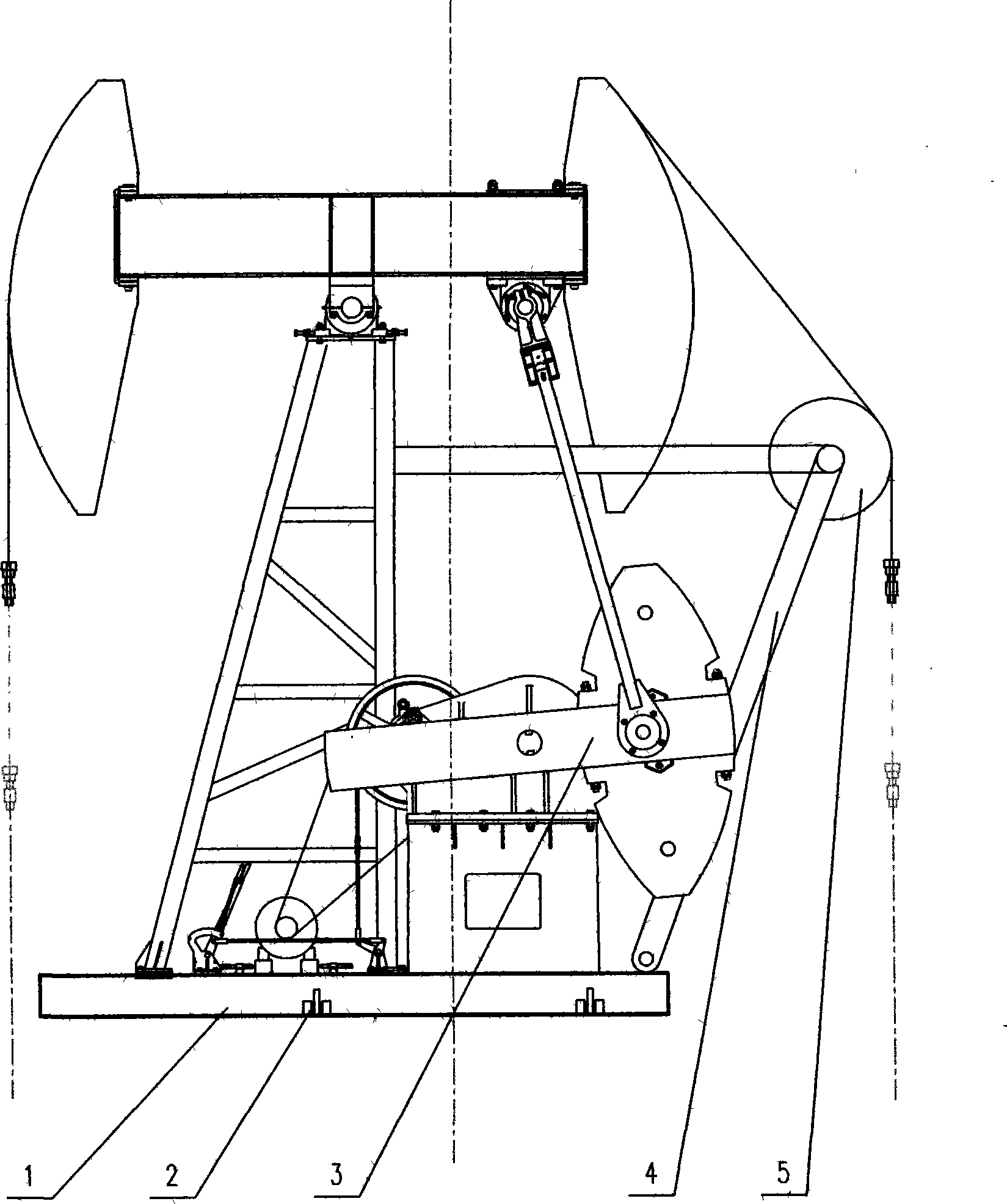

[0012] Now in conjunction with accompanying drawing and specific embodiment the present invention is further described as follows:

[0013] As can be seen from the accompanying drawings, the rotary base (1) of the present invention is achieved through the following technical proposals. There are four sets of rollers (2) on both sides of the double well pumping unit base (1). When the rotary pumping unit First fix the center of rotation, loosen the fixing bolts of the base (1), support the rollers (2), the four sets of rollers (2) roll on the ring track on the cement foundation to rotate the double well pumping unit 180 degrees, turn the The two ends of the double well pumping unit are interchangeable.

[0014] As can be seen from the accompanying drawings, the support arm (4) with the runner (5) of the present invention is realized through the following technical proposals, on the double well pumping unit base (1) near the crank (3) side A support arm (4) has a runner (5) on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com