Active matrix driven grating light modulator

An optical modulator and active matrix technology, which is applied in the field of grating optical modulators, can solve the problems of low light utilization and low contrast, and achieve the effects of improving contrast, eliminating cross effects, and reducing dynamic response time requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

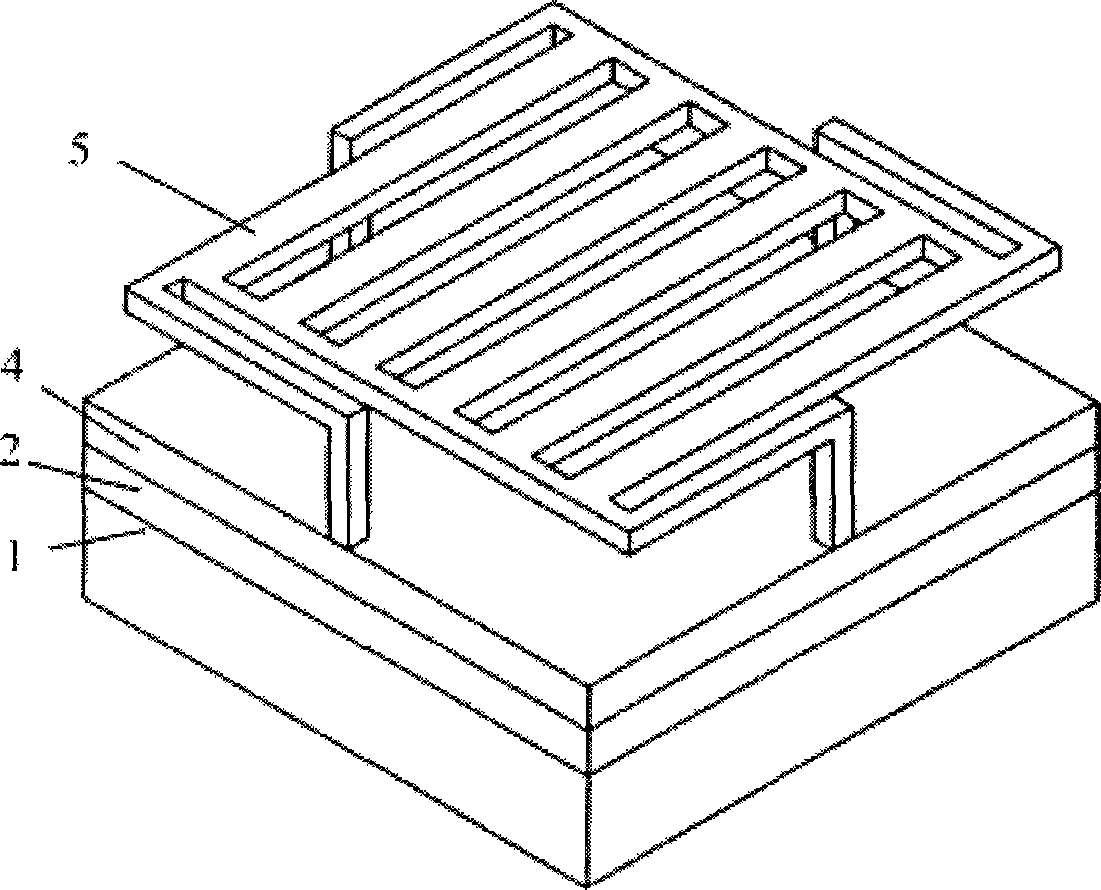

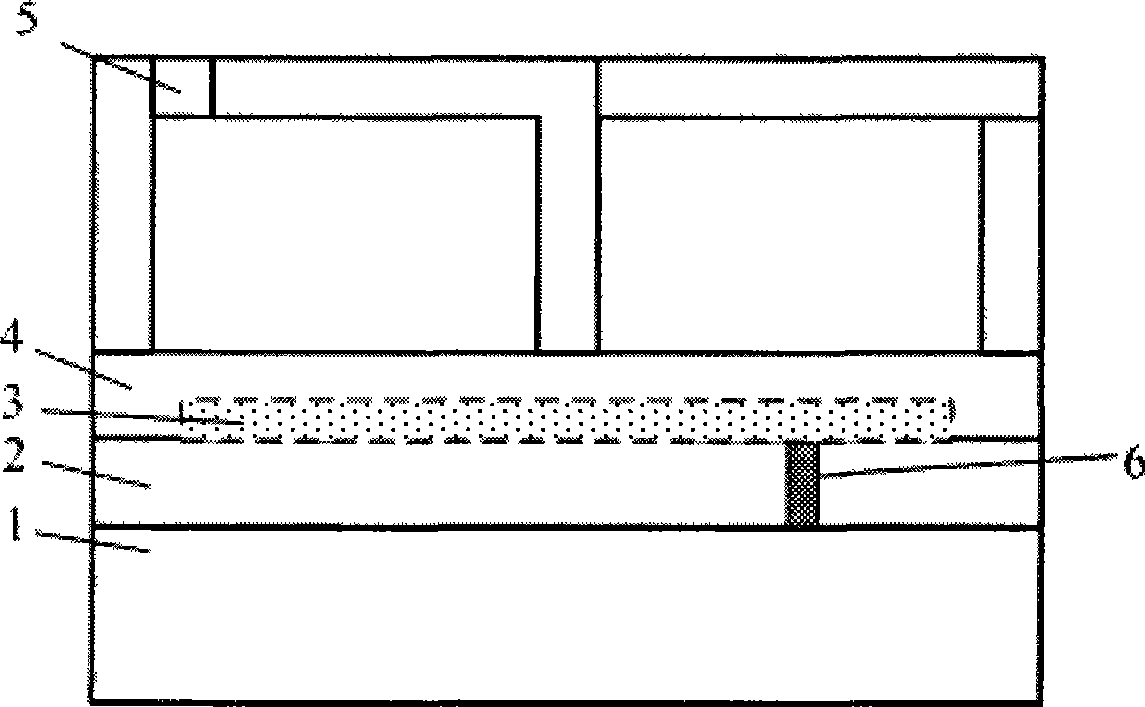

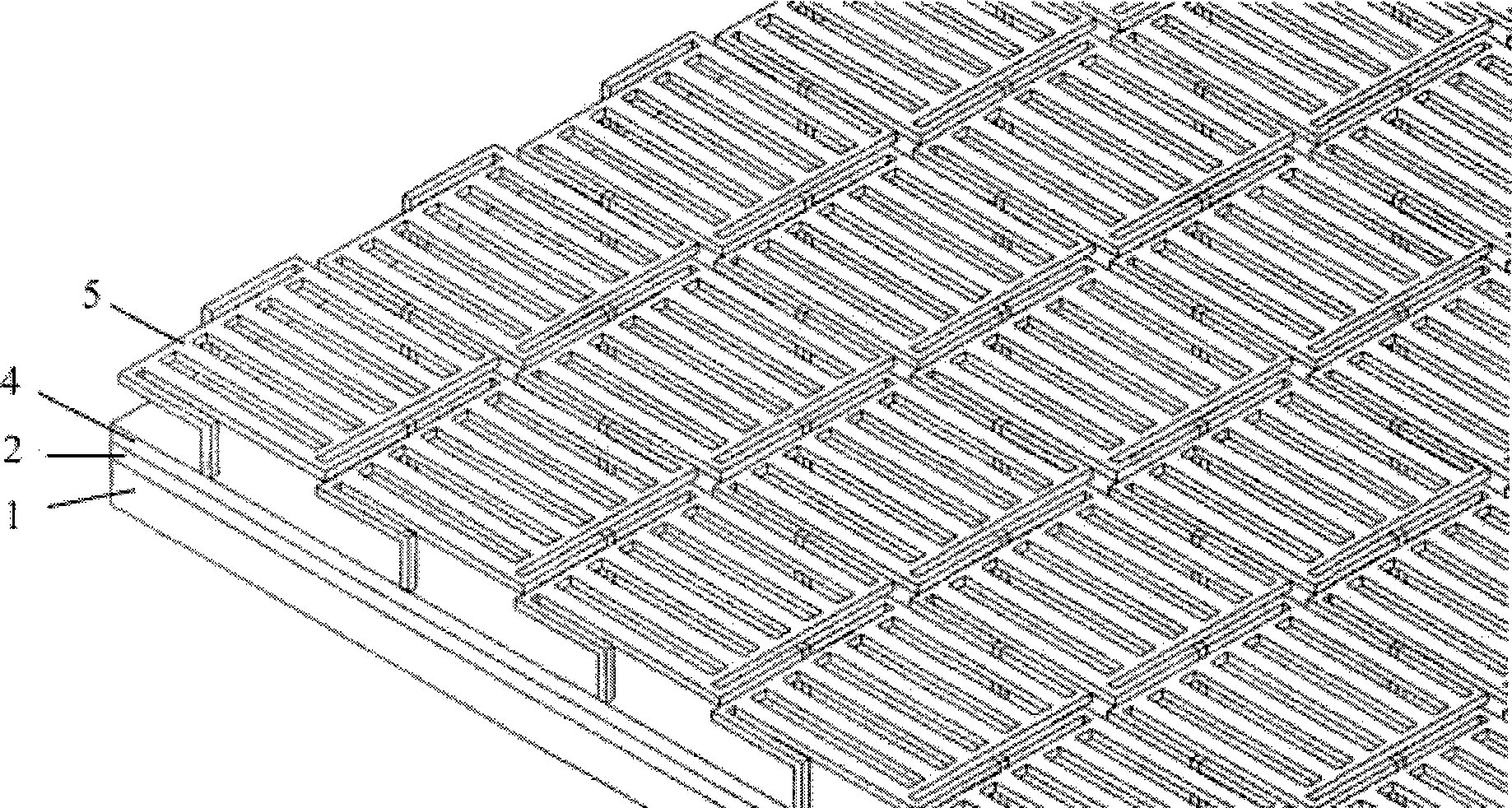

[0022] In Figure 1(a) and Figure 1(b), the processing technology of the grating light modulator driven by the active matrix: first, the active matrix unit 1 is processed on the silicon substrate by using the CMOS process; then the oxide layer 2 is deposited , etch the through hole 6; then use chemical mechanical polishing technology (CMP) to polish, deposit and etch the lower electrode 3 of the grating light modulator; then deposit the insulating layer 4; finally, use the surface micromachining technology to form a movable upper layer Grating 5. The through hole 6 connects the upper layer MEMS grating light modulator and the lower layer active matrix unit 1, so that independent control of each grating light modulator can be realized. The active matrix driven grating light modulator eliminates the cross effect existing in the passive matrix driven grating light mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com