Semiconductor chip pickup apparatus and pickup method

A pick-up device and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of semiconductor chip damage, maintaining sheet peeling residue, damage to semiconductor chips, etc., to achieve the effect of easy picking up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

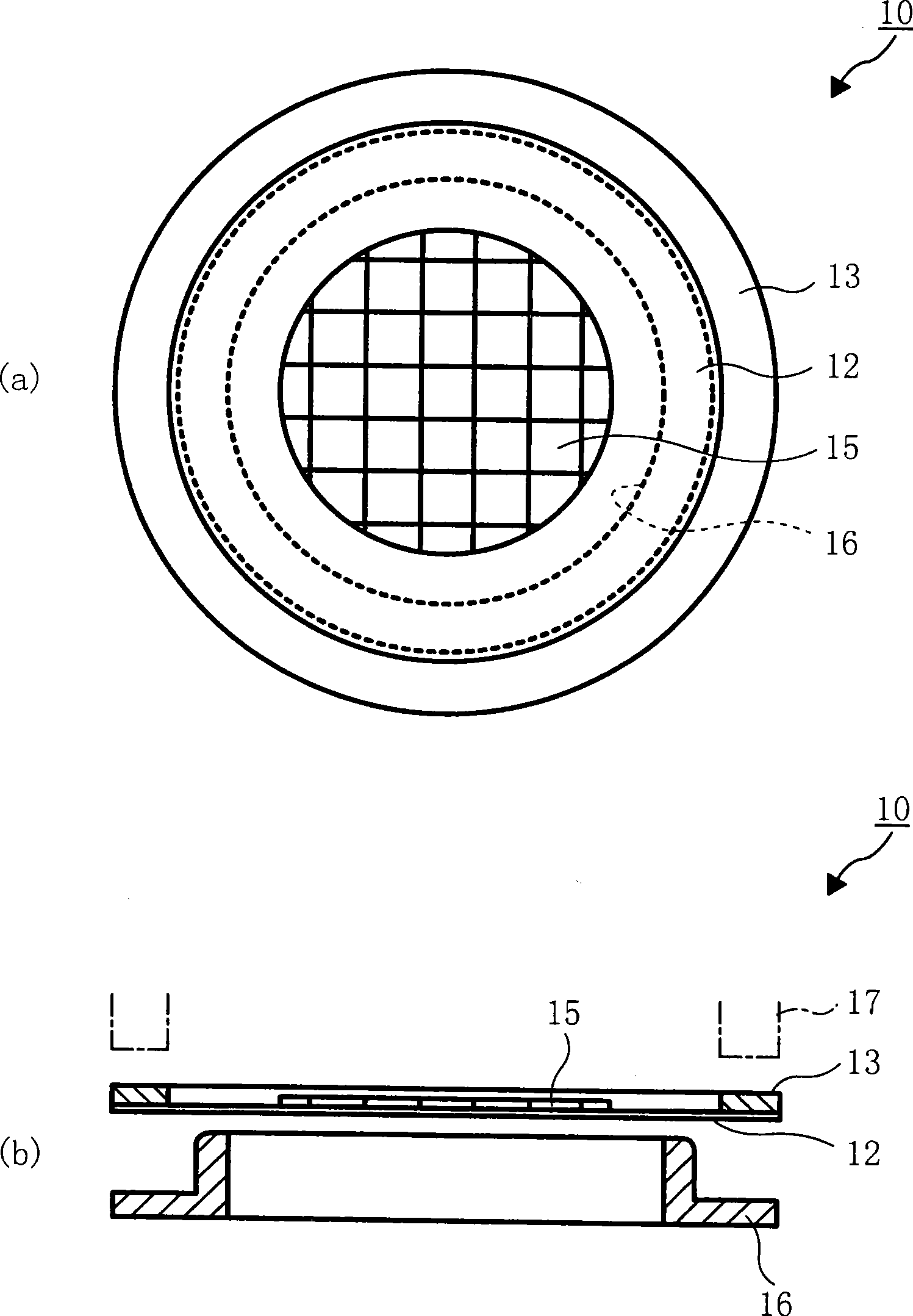

[0082] Hereinafter, suitable embodiments of the present invention will be described with reference to the accompanying drawings. In the following embodiments, although various limitations are made to constituent elements, types, combinations, shapes, relative arrangements, etc., these are merely examples, and the present invention It is not limited to this.

[0083] Before describing the semiconductor chip pick-up device of the present invention, the wafer and the wafer holder will be described first.

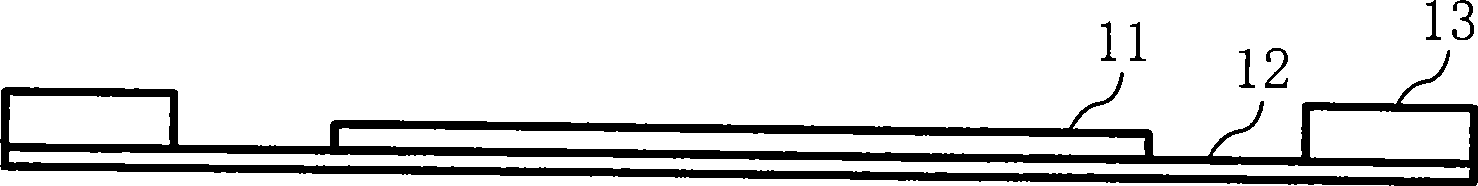

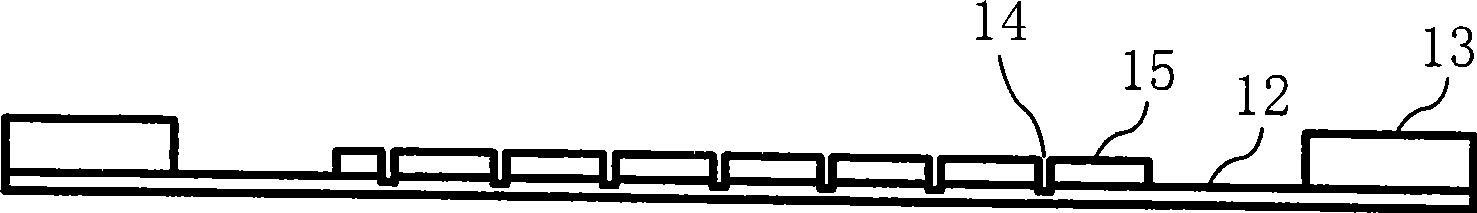

[0084] Such as figure 1 As shown, an adhesive holding sheet 12 is pasted on the back of the wafer 11 , and the holding sheet 12 is attached to a metal ring 13 . In this way, the wafer 11 is conveyed while being attached to the metal ring 13 via the holding sheet 12 . Then, if figure 2 As shown, in the cutting step, the wafer 11 is cut from the front side by a cutting blade or the like to form individual semiconductor chips 15 . Cut-in gaps 14 formed during dicing are form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com