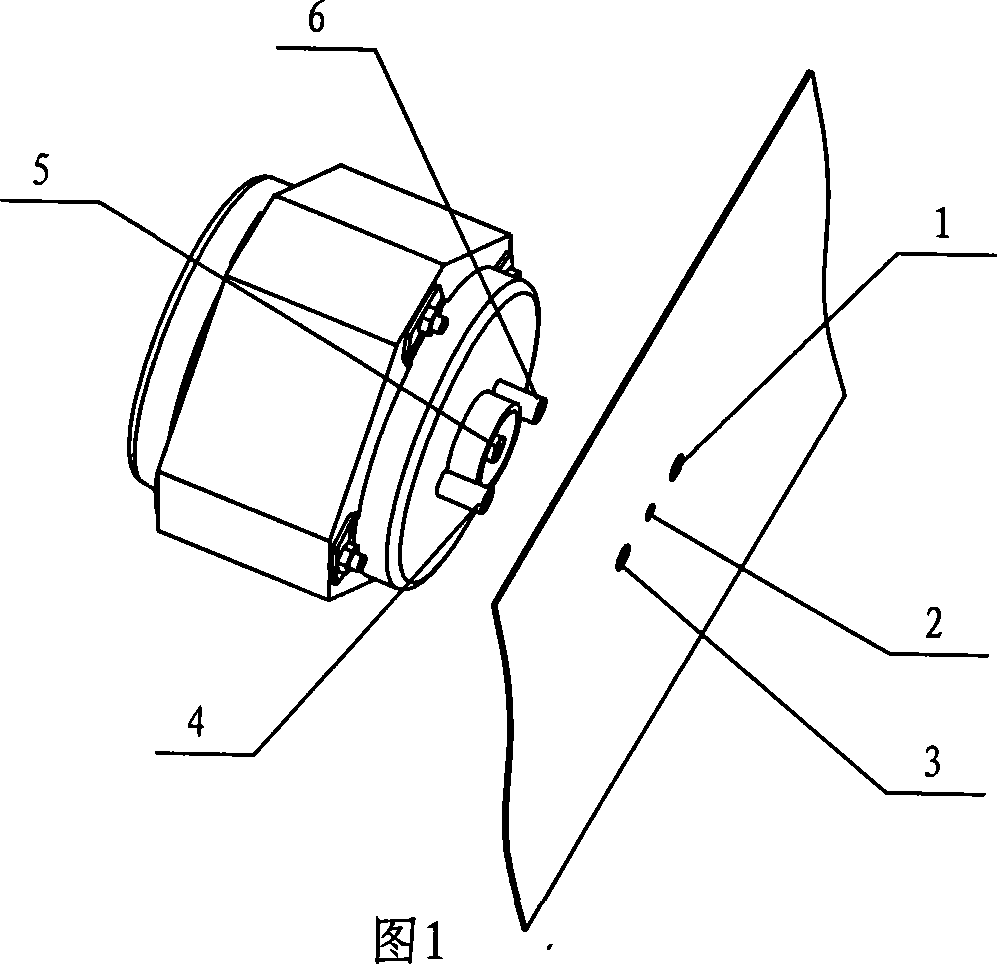

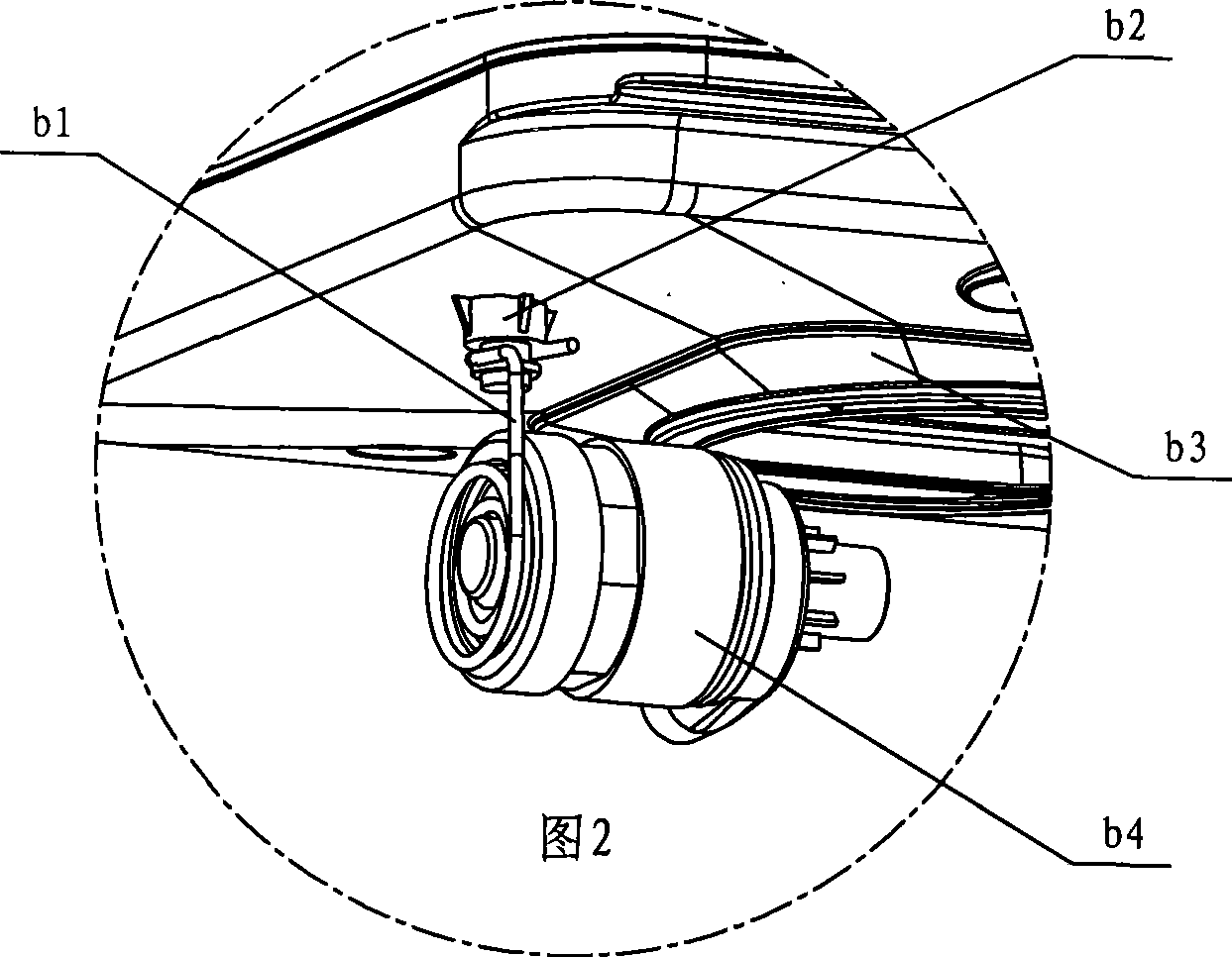

Electric machine mounting structure of bowl washer

An installation structure, a dishwasher technology, applied in the direction of washing machine/rinsing machine parts of tableware, etc., can solve the problems of washing motor damage, dislocation, easy detachment of the motor, etc., to improve reliability and stability, and reduce production costs. , the effect of improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

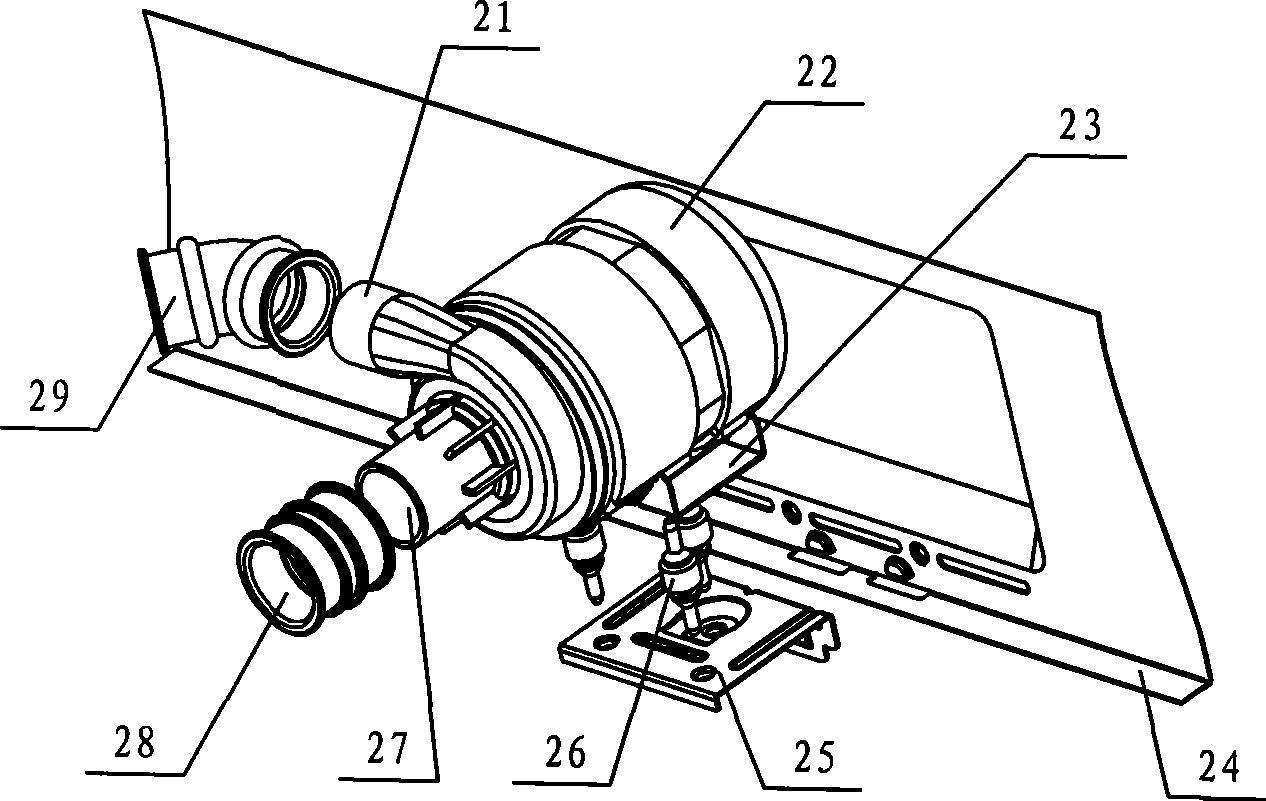

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] see image 3 , the motor installation structure of the dishwasher includes a motor 22 arranged in the fuselage, a mount 23 is arranged on the motor, the mount is arranged under the motor 22, and an inverted U-shaped support 25 is arranged on the fuselage . Three elastic pieces 26 are arranged between the mounting base 23 and the support 25, the middle of the elastic piece is large, and the two ends are small. The plates 24 are rigidly connected, and the elastic members 26 are evenly distributed on the mounting base 23 . The motor 22 is provided with a water inlet 27 and one or more water outlets 21 . The water inlet 27 and the water outlet 21 are respectively connected with the elastic connecting pipes 28 and 29 to the water cup or other water flow paths directly or indirectly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com