Spray paining control method on mineral wool sound-absorbing panel and control system thereof

A mineral wool sound-absorbing panel and a control method technology, which are applied to the device for coating liquid on the surface, the electric fluid pressure control, the flow control using the electric device, etc., can solve the problem of large deviation between the actual flow and the set flow, The actual flow fluctuates greatly, and it takes a long time to reach stability, so as to shorten the response time, improve the control accuracy, and eliminate the fluctuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

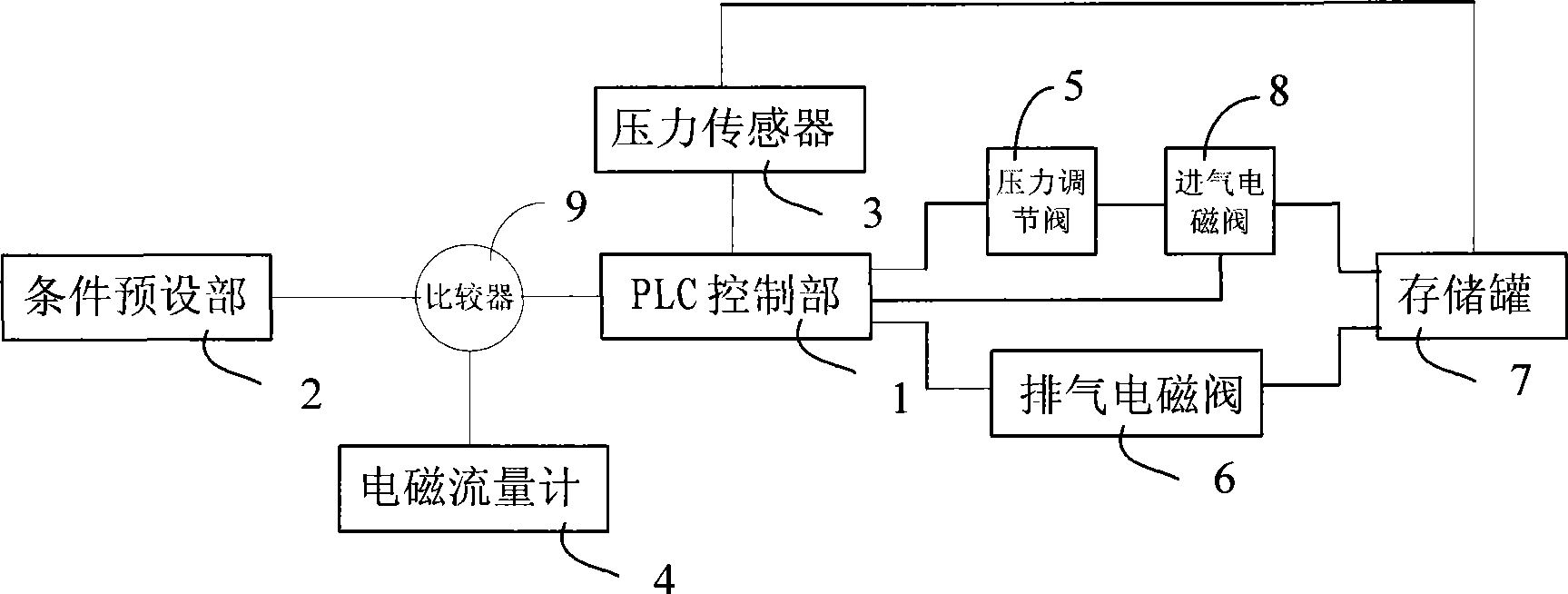

[0018] The method for controlling the surface of the sprayed plate of the present invention is specifically as follows: First, the worker pre-sets a given amount of spraying flow in the condition presetting part 2, and the given amount of spraying can achieve the best spraying effect. Before starting to spray the surface of the sheet, the initial spraying pressure must be set in the condition preset part 2. The pressure sensor 3 first detects the pressure in the storage tank 7 and inputs the detection result to the PLC control part 1. The PLC control unit 1 compares the aforementioned initial spraying pressure with the detection result, and adjusts the opening degree of the pressure regulating valve 5 installed on the storage tank 7 and the opening and closing status of the exhaust solenoid valve 6 to control the initial pressure in the storage tank 7. By controlling the initial pressure in the storage tank 7 within an appropriate range, the response time for the actual spraying f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com